A rare earth ore screening machine

A technology of rare earth ore and sieving machine, which is applied in the fields of filtration and sieving, solid separation, chemical instruments and methods, etc. It can solve problems such as fatigue, inconvenient access to rare earth ore, and labor-intensive sieving, so as to reduce work burden and improve The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

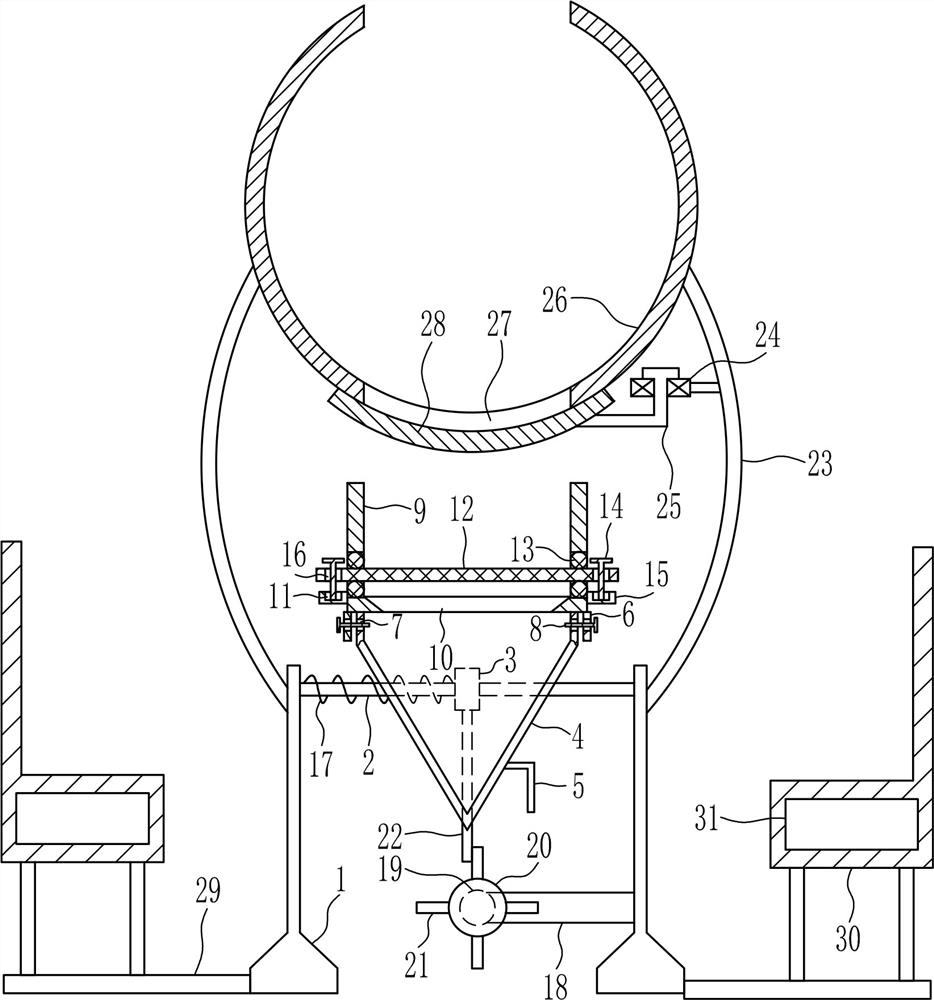

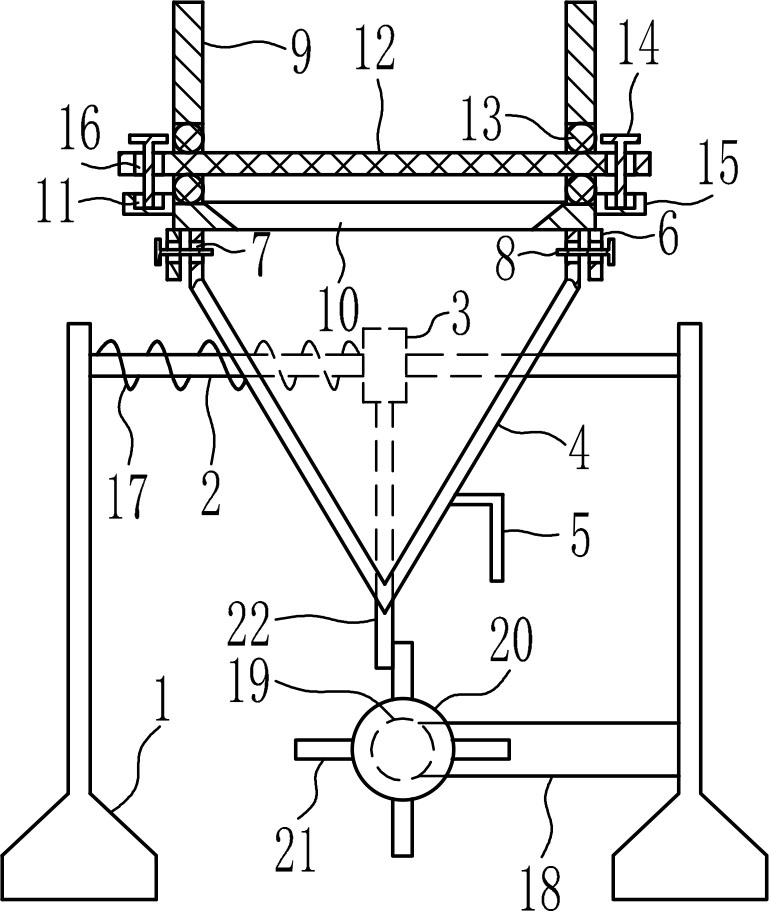

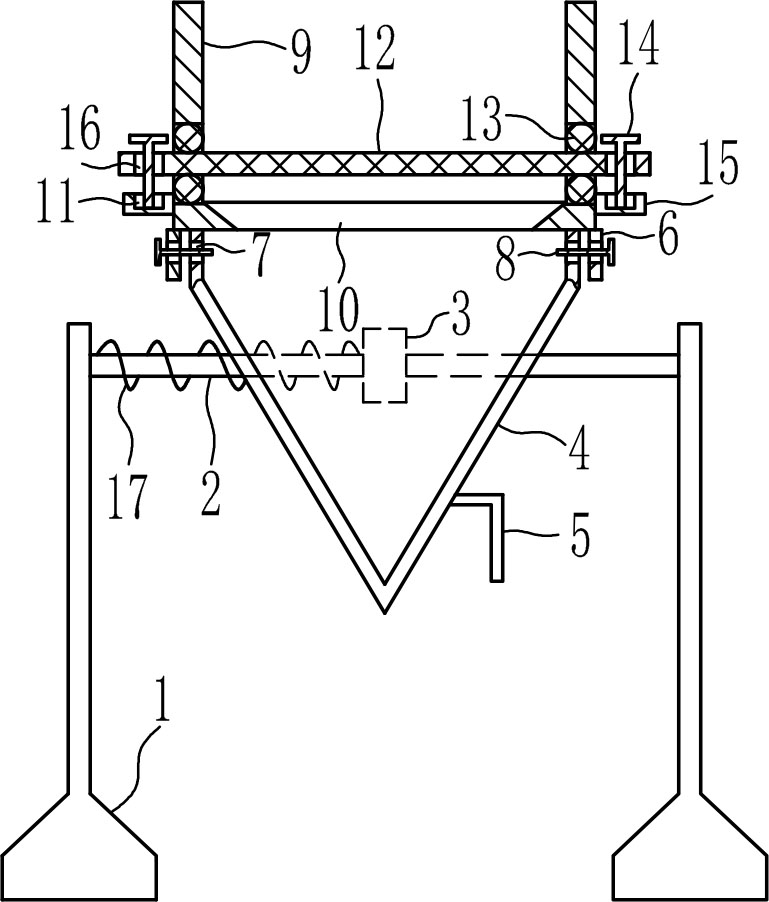

[0025] A rare earth ore screening machine, such as Figure 1-5 As shown, it includes installation column 1, guide rail 2, sliding sleeve 3, collection frame 4, handle 5, support rod 6, bolt 8, screen frame 9, filter plate 12, sealing ring 13, screw rod 14, fixing block 15 and the first spring 17, a guide rail 2 is connected between the inner upper parts of the two installation columns 1, a sliding sleeve 3 is slidably connected on the guide rail 2, and a sliding sleeve 3 is connected between the left side of the sliding sleeve 3 and the upper right side of the left installation column 1. The first spring 17, the guide rail 2 passes through the first spring 17, the front side of the sliding sleeve 3 is connected to the collection frame 4, the top of the collection frame 4 is connected to the sieve frame 9, and the bottom wall of the sieve frame 9 has a first through hole 10, The lower part of the sieve frame 9 is provided with a filter screen plate 12, the filter screen plate 1...

Embodiment 2

[0027] A rare earth ore screening machine, such as Figure 1-5As shown, it includes installation column 1, guide rail 2, sliding sleeve 3, collection frame 4, handle 5, support rod 6, bolt 8, screen frame 9, filter plate 12, sealing ring 13, screw rod 14, fixing block 15 and the first spring 17, a guide rail 2 is connected between the inner upper parts of the two installation columns 1, a sliding sleeve 3 is slidably connected on the guide rail 2, and a sliding sleeve 3 is connected between the left side of the sliding sleeve 3 and the upper right side of the left installation column 1. The first spring 17, the guide rail 2 passes through the first spring 17, the front side of the sliding sleeve 3 is connected to the collection frame 4, the top of the collection frame 4 is connected to the sieve frame 9, and the bottom wall of the sieve frame 9 has a first through hole 10, The lower part of the sieve frame 9 is provided with a filter screen plate 12, the filter screen plate 12...

Embodiment 3

[0030] A rare earth ore screening machine, such as Figure 1-5 As shown, it includes installation column 1, guide rail 2, sliding sleeve 3, collection frame 4, handle 5, support rod 6, bolt 8, screen frame 9, filter plate 12, sealing ring 13, screw rod 14, fixing block 15 and the first spring 17, a guide rail 2 is connected between the inner upper parts of the two installation columns 1, a sliding sleeve 3 is slidably connected on the guide rail 2, and a sliding sleeve 3 is connected between the left side of the sliding sleeve 3 and the upper right side of the left installation column 1. The first spring 17, the guide rail 2 passes through the first spring 17, the front side of the sliding sleeve 3 is connected to the collection frame 4, the top of the collection frame 4 is connected to the sieve frame 9, and the bottom wall of the sieve frame 9 has a first through hole 10, The lower part of the sieve frame 9 is provided with a filter screen plate 12, the filter screen plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com