Capsule brewing machine

A brewing machine and capsule technology, which is applied in the field of beverage preparation equipment, can solve the problems of incomplete brewing of the material to be brewed and affect the taste of the brewed beverage, and achieve the effect of ensuring the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

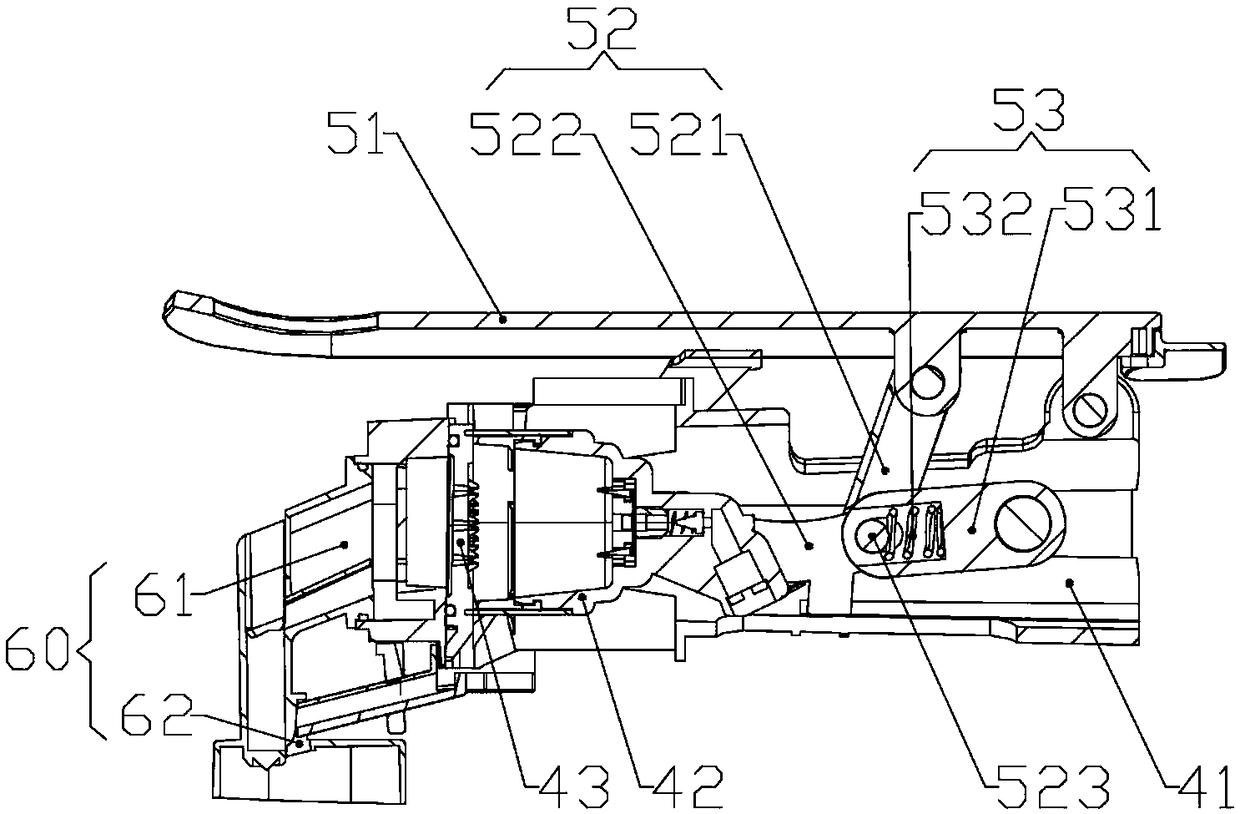

[0046] Please refer to Figure 1-8 , a brewing device of a capsule brewing machine, including a brewing mechanism 40 and a driving mechanism 50, the brewing mechanism 40 includes a mounting seat 41, and a water guide assembly 42 and a drainage assembly 43 arranged on the mounting seat 41. The water guide assembly 42 and the drainage assembly 43 cooperate to form a brewing chamber for accommodating capsules, and the water flow enters the brewing chamber from one side of the water guide assembly 42 and is discharged from the side of the drainage assembly 43, so that The drainage assembly 43 is provided with drainage holes for discharging brewing liquid.

[0047] The water guiding component 42 has a first perforation member 421 for piercing the water inlet side of the capsule, and the drainage component 43 has a second perforation member 431 for piercing the water outlet side of the capsule. The water guiding component 42 is slidably matched with the mounting seat 41, and can be...

Embodiment 2

[0058] Please refer to Figure 9-10 , a heating mechanism 30 of a capsule brewing machine, including a heating assembly 31 and a temperature sensor 32, the heating assembly 31 includes a heating chamber 311 and a heating tube 312 arranged in the heating chamber 311, the heating chamber 311 A boss 311-A protrudes into the heating chamber 311 on both the top and bottom surfaces thereof, and the heating tube 312 is arranged around the boss 311-A. The heating tube 312 generates heat in the form of electric heating, and the electric heating technology is a prior art, which is not the invention point of the present invention, so it will not be repeated here.

[0059] The heating pipe 312 heats the water flow in the heating chamber 311, and due to the setting of the boss 311-A, the water in the heating chamber 311 is located around the boss 311-A, and the The heating tube 312 surrounds the boss 311-A, so that the heating tube 312 can fully contact with the water in the heating chamb...

Embodiment 3

[0063] Please refer to Figure 7-8 , a return element 70 of a capsule brewing machine, comprising a connected collection part 71 and a flow guide part 72, the top surface of the flow guide part 72 is provided with a collection groove 711 for collecting brewing liquid, and the guide part A diversion pipe connected to the collection tank 711 is provided in the flow portion 72 , and the diversion pipe is inclined to the horizontal plane for guiding the brewing liquid into the water container.

[0064] In the embodiment, the collection part 71 has a central axis, and the collection part 71 is symmetrical about the central axis, so as to achieve the purpose of sufficient collection, and avoid the excessive collection area on one side of the collection part 71 and the collection area on one side. insufficient. The flow guiding part 72 is arranged in the middle of the collecting part 71 , so as to collect the brewing liquid collected on both sides of the collecting part 71 .

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com