Wind tunnel test section replacement method

A wind tunnel test and replacement method technology, which is applied in the field of aerospace wind tunnel tests, can solve the problems of inconvenient steering, inaccurate positioning, and the need to turn the running mechanism, etc., to improve preparation efficiency, reduce infrastructure costs, and reduce test costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

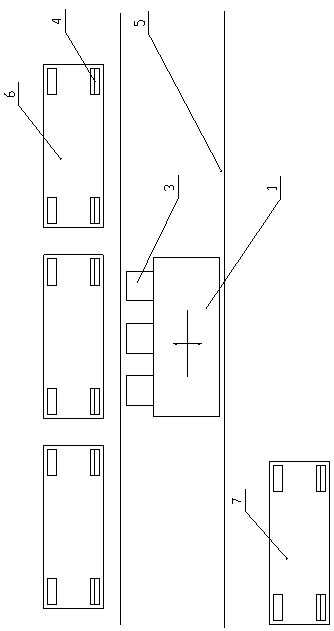

[0054] (1) The following process is the transfer process of the wind tunnel test section from the working station inside the wind tunnel to the parking station outside the wind tunnel. At this time, the wind tunnel test section has been disconnected from other sections, and the relevant pipelines have also been disconnected .

[0055] Its operation steps are as follows.

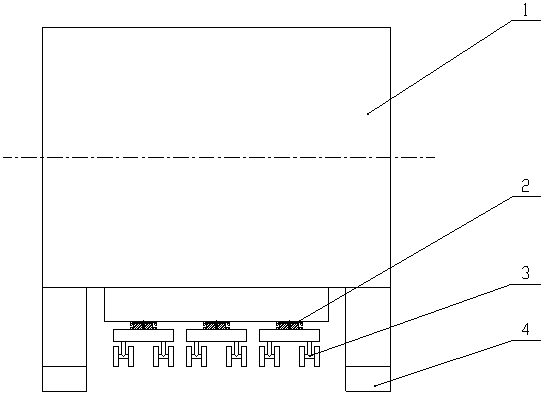

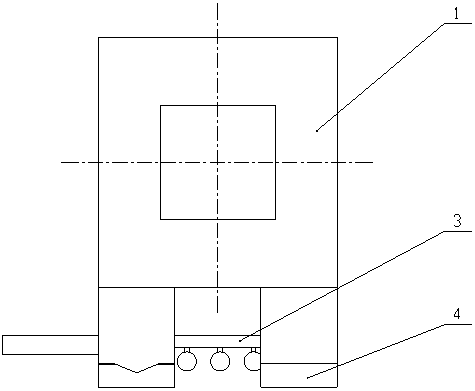

[0056] a. According to the weight of the wind tunnel test section, select the number of vehicles in parallel (that is, the number of transport vehicles), and the remote control transport vehicle drives under the wind tunnel test section at the working station in the wind tunnel.

[0057] b. The height adjustment unit of the remote control transport vehicle rises, so that the V-flat guide rail used for positioning and loading is separated from the wind tunnel test section.

[0058] c. The transport vehicle and the wind tunnel test section leave the working station in the wind tunnel together and move to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com