Metal container

A metal container and container technology, applied in the direction of containers, rigid containers, packaging, etc., can solve the problems that the items cannot be taken out at one time and taken out in layers, and the particles are inconvenient to take out, so as to achieve stability, structural stability, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

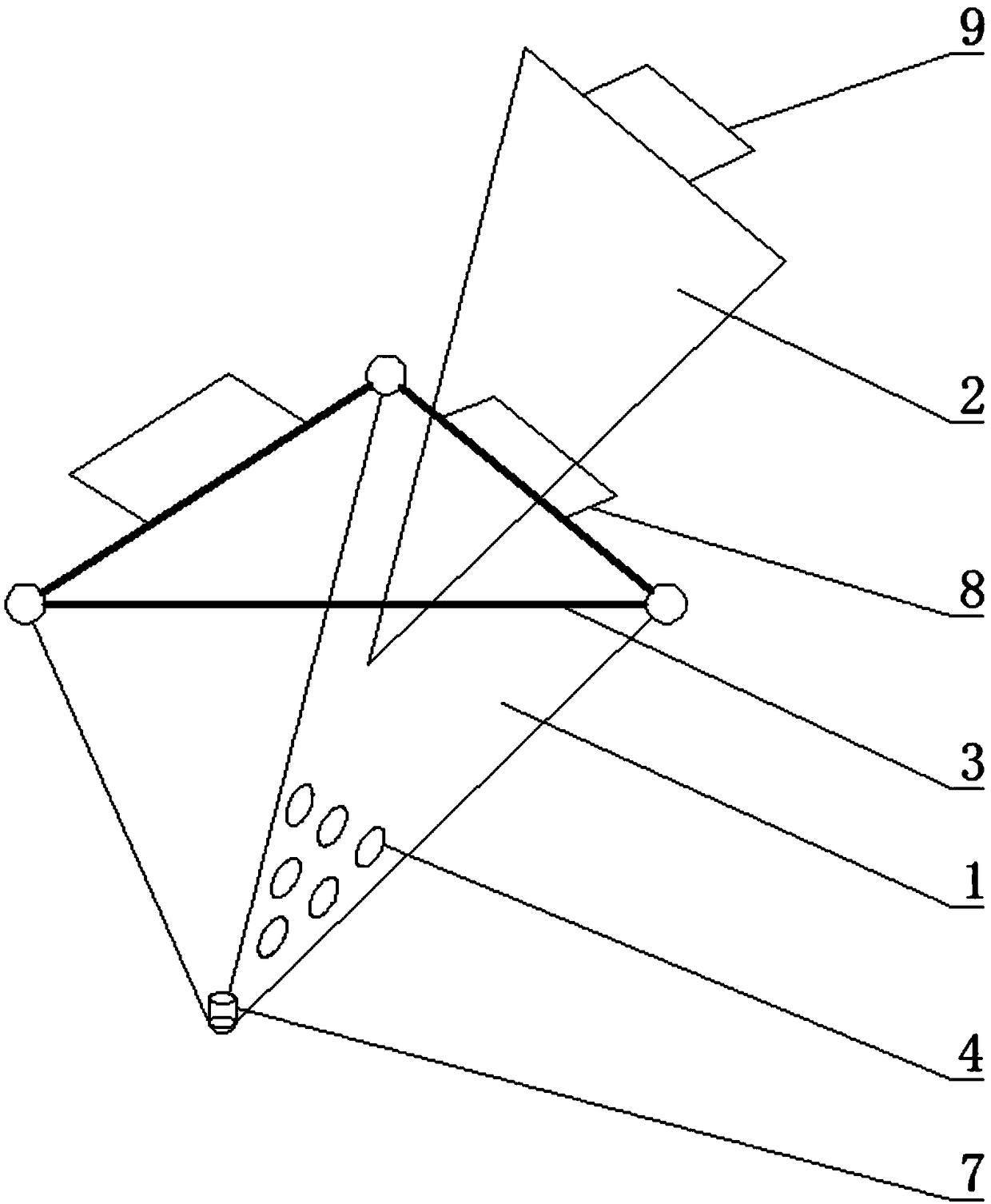

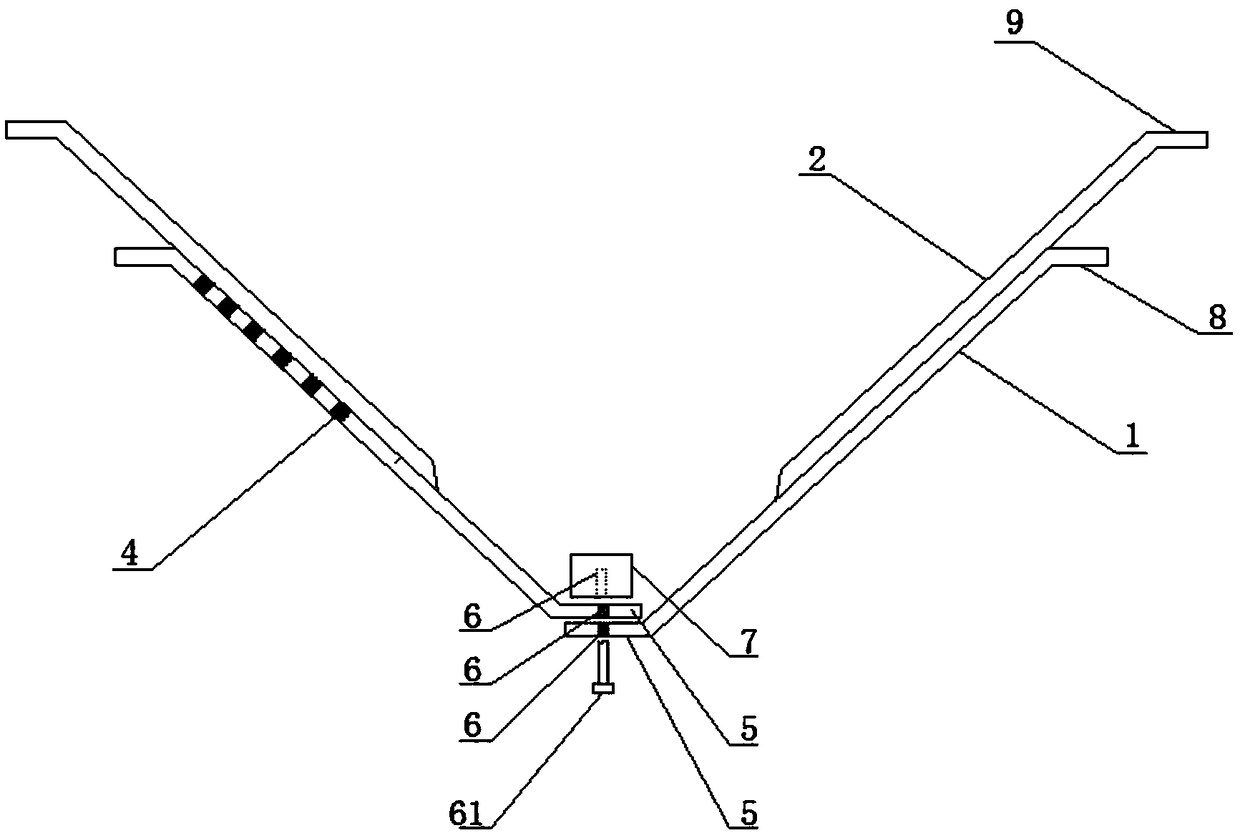

[0019] Such as figure 1 with figure 2 As shown, a metal container includes three triangular plates 1 and three triangular plug-in plates 2; the three triangular plates 1 are matched in size and shape, and the three triangular plates 1 are spliced into a prism container with a triangular prism structure; The container of the prism structure is placed upside down, and its upper end is set as an open end after being placed upside down; and the upper ends of the three triangular plates 1 are hinged and installed into one body through the hinge shaft 3 provided; and the intersection of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com