Baler side exit hatch

A technology of a baler and a hatch door, applied in the field of balers, can solve the unreasonable design of the position of the bag outlet and the opening and closing structure of the hatch door, the difficulty of implementing and breaking through the baler packaging process, and the inability to apply the structural design of the side outlet, etc. problems, to achieve the effect of facilitating promotion and application, optimizing and adjusting the operation area, and facilitating collaborative operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

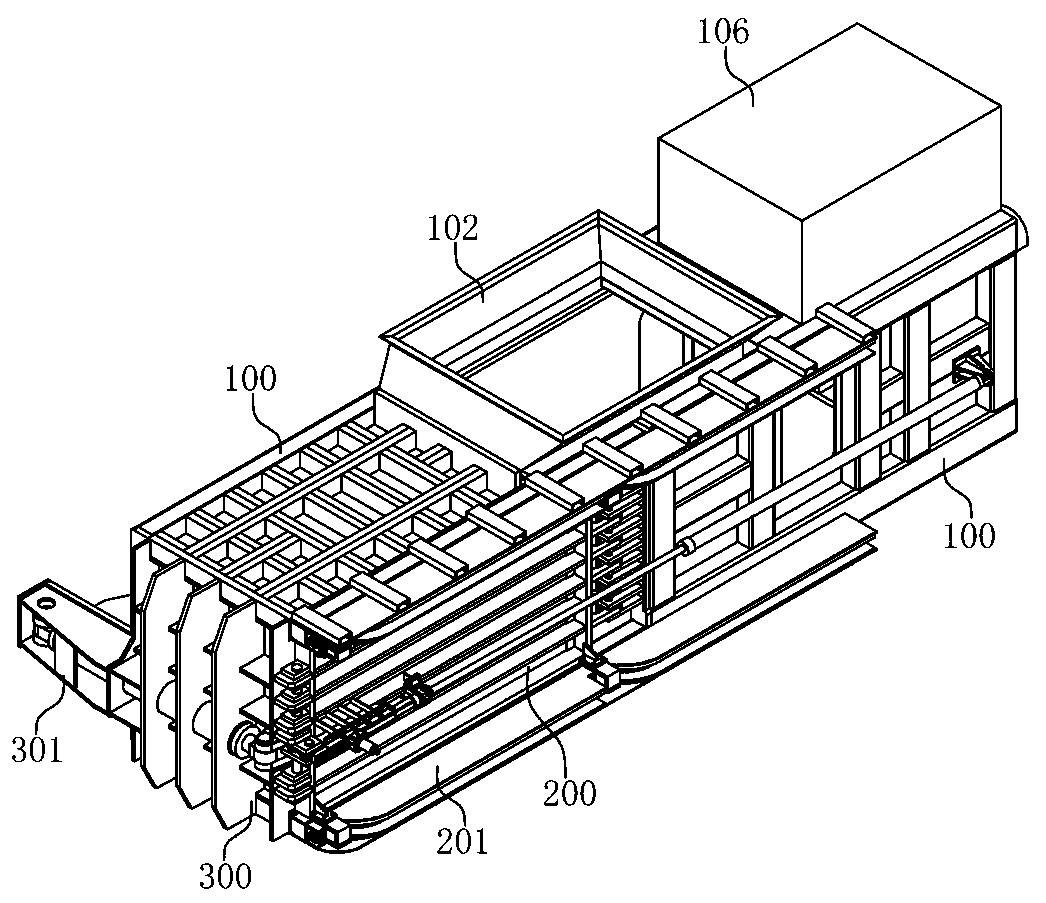

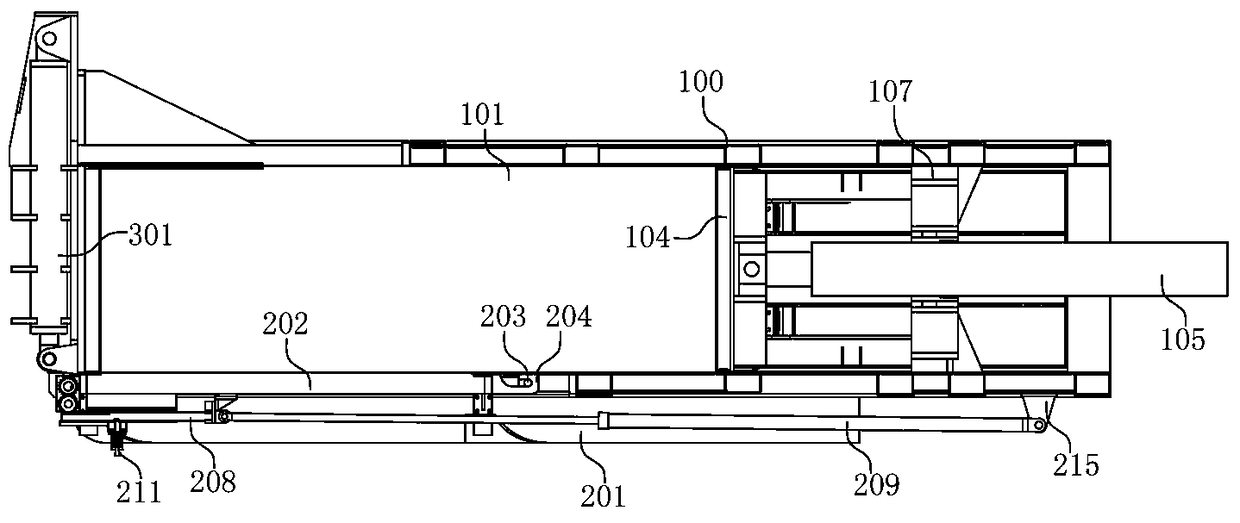

[0039] Embodiment 1: This embodiment discloses a side discharge bag hatch of a baler, which is correspondingly assembled on a side discharge horizontal baler, such as figure 1 As shown, the side discharge horizontal baler includes a frame 100, a bag outlet 103, a hatch 200 and a tailgate 300. A packing chamber 101 is provided inside the frame 100, and a feeding chamber 101 is provided at the front end of the packing chamber 101. Port 102 and push plate assembly, wherein the push plate assembly includes push plate 104, push plate oil cylinder 105 and pump station group 106; bag outlet 103 is arranged on the side of the rear end of packing chamber 101; hatch 200 is set corresponding to bag outlet 103 The rear baffle 300 is arranged at the rear of the packing chamber 101 and corresponds to the push plate 104 , and the rear baffle 300 is provided with a bag-out device 301 corresponding to the bag-out port 103 .

[0040]Concretely, the baler side delivery hatch door in this embodim...

Embodiment 2

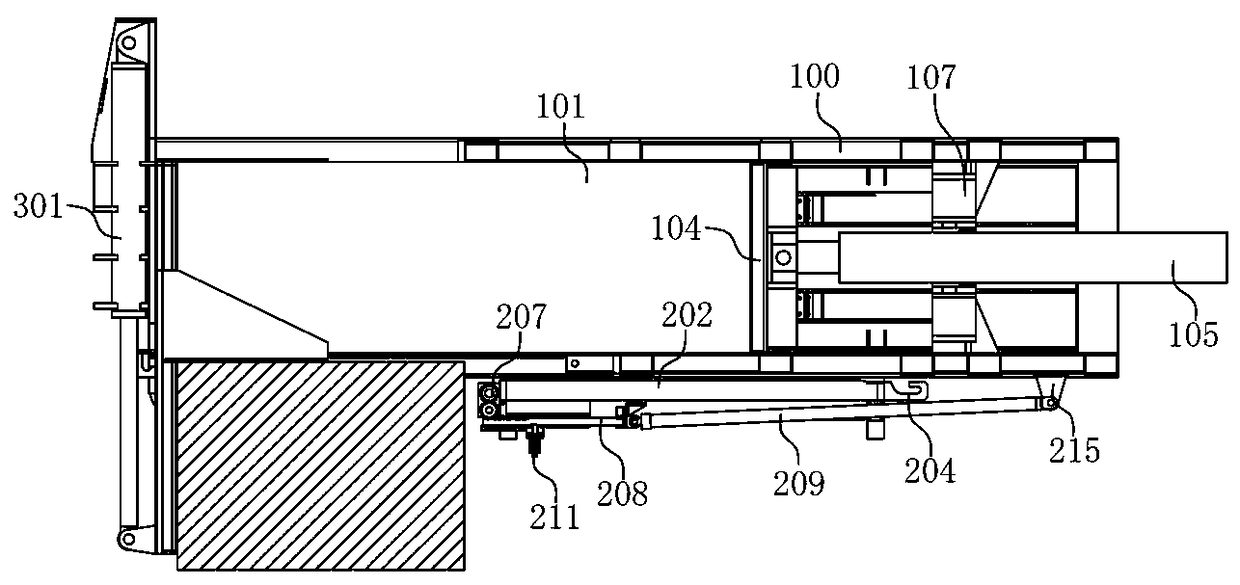

[0049] Embodiment 2: In combination with the specific positional relationship and connection relationship, the following further details are carried out for its specific structure and movement mode:

[0050] The specific door body is composed of a door frame and a fence, and a rope is left between the fences. The four jiaos of door frame are equipped with guide wheel group 214. The fixed plate 217 of the power mechanism of the door lock mechanism is housed on the fence plate, and the door-opening pull plate 212 is installed near the middle position. One set of bolt shafts and lock hooks is provided with a door lock mechanism, which is provided on the bolt shafts and lock hooks near the tailgate in this embodiment and the accompanying drawings; specifically, the bolt shaft 203 is a cylinder, There are some locking openings 205 on it. A bolt shaft gear 207 is fixed near the center of the bolt shaft 203, and the gear keeps rotating synchronously with the bolt shaft through a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com