Mounting bracket for engine room of electric motor coach

An engine compartment and mounting bracket technology, applied in electric power units, power units, vehicle components, etc., can solve problems such as poor stability, difficult hole alignment, engine misalignment, etc., to enhance equipment performance, improve stability, Avoid misplaced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

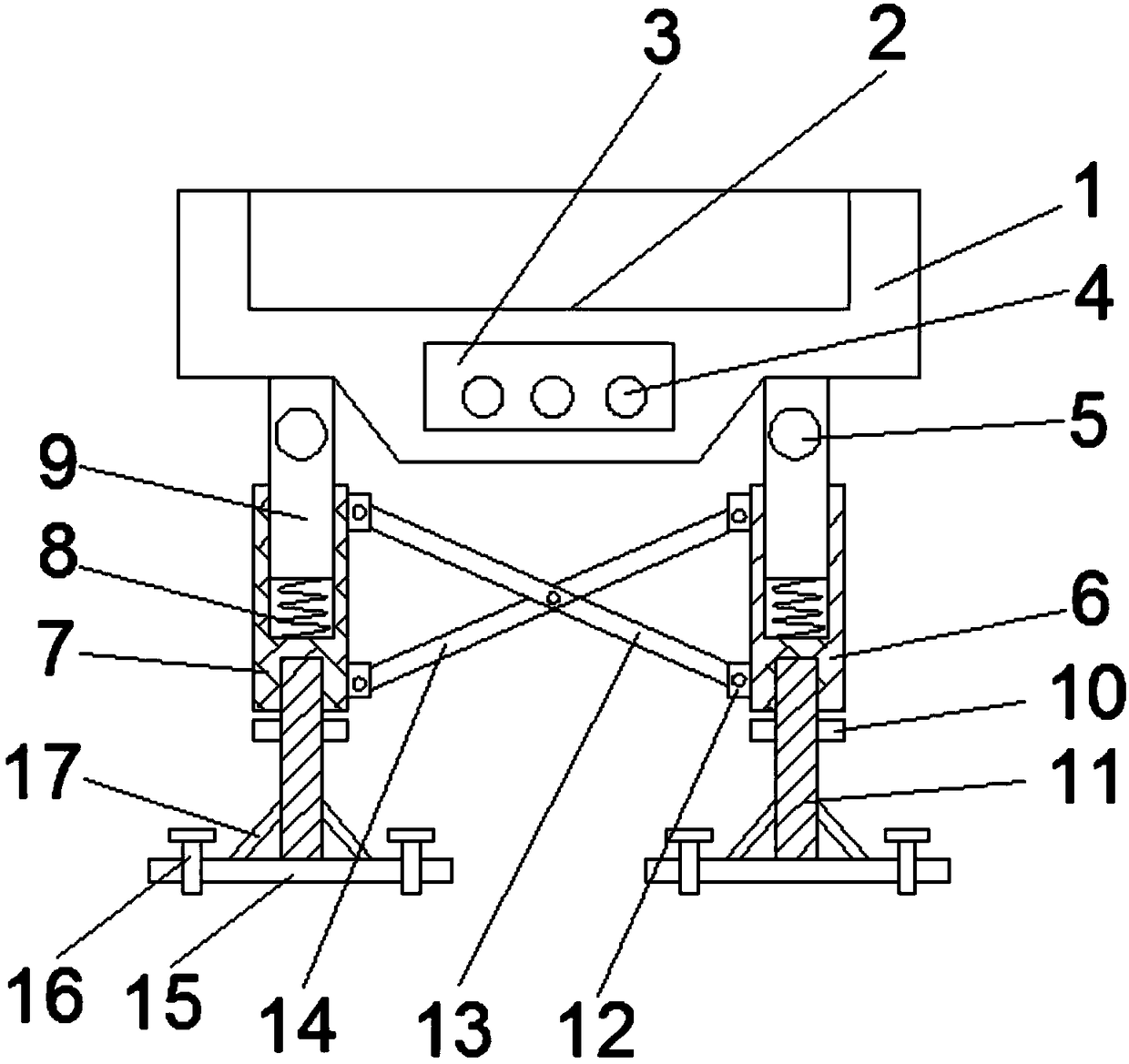

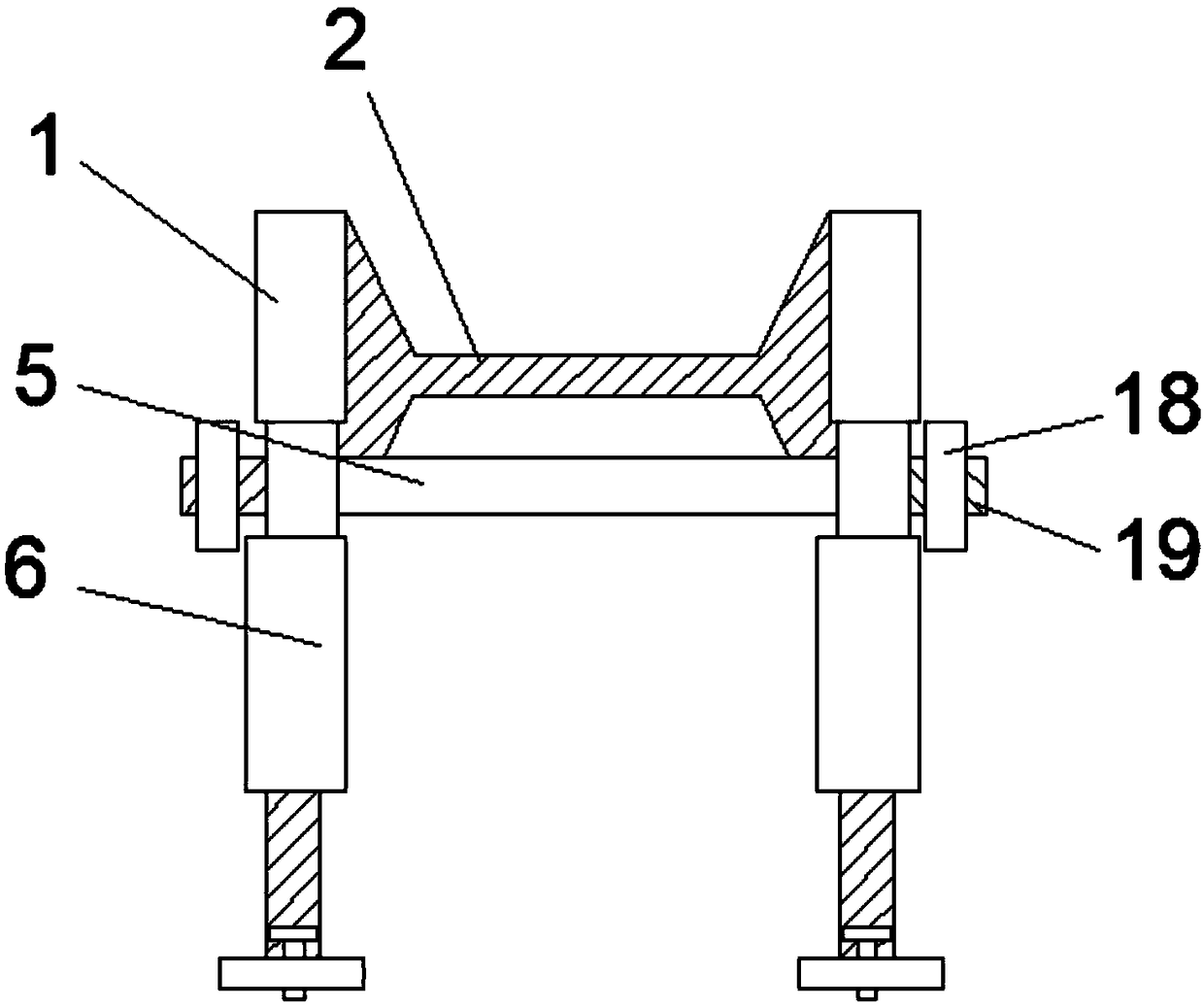

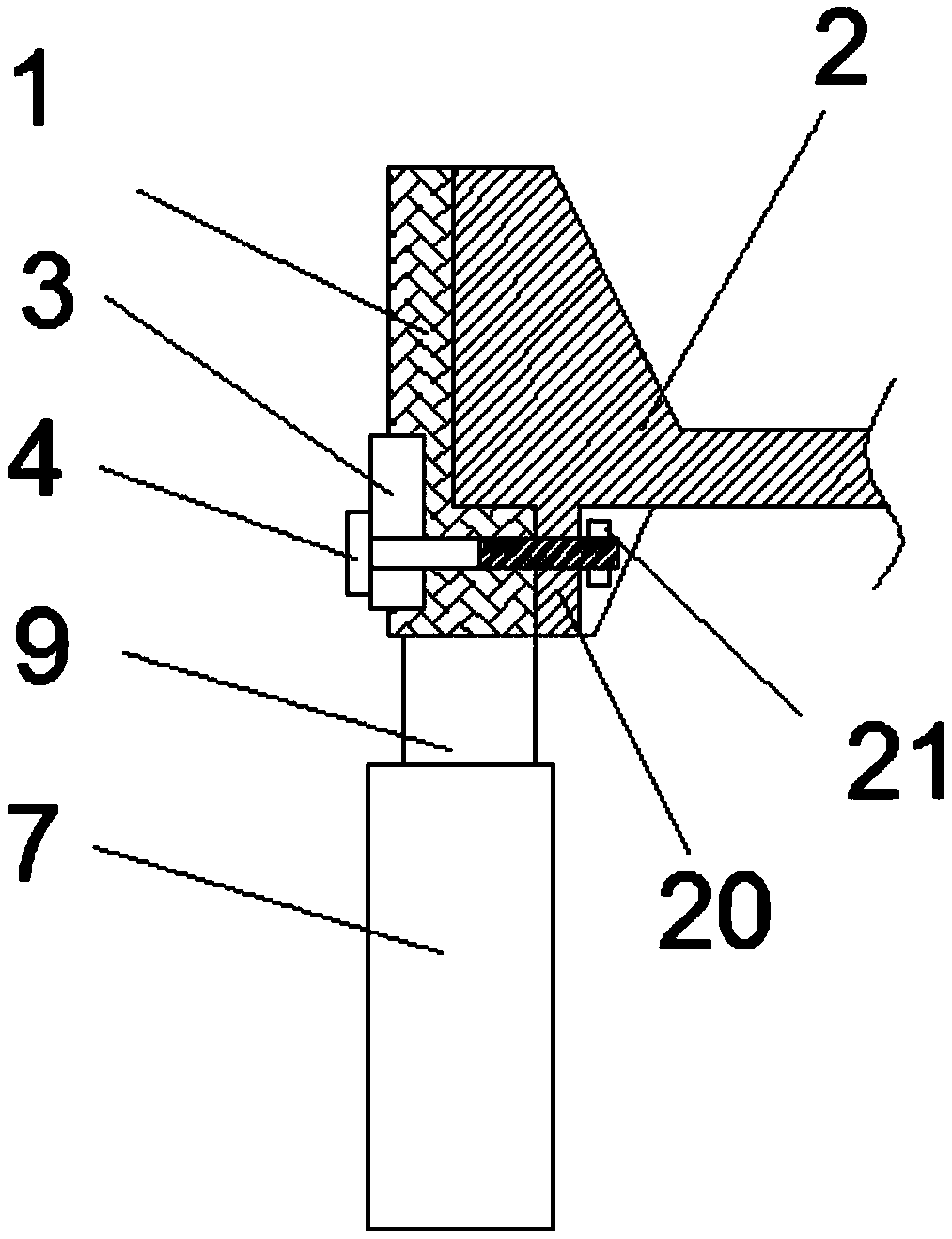

[0021] Such as Figure 1-Figure 3 As shown, a mounting bracket for an engine compartment of an electric passenger car proposed by the present invention includes a mounting plate 1, an engine compartment 2, and a base 15, an engine compartment 2 is provided on the upper inner side of the mounting plate 1, and mounting plates are provided at the front and rear ends of the mounting plate 1. The fixing block 3 is provided with a plurality of engine compartment fixing bolts 4 inside the mounting plate fixing block 3, and engine compartment fixing seats 20 are arranged on the front and rear sides of the lower end of the engine compartment 2;

[0022] The left and right sides of the lower end of the mounting plate 1 are provided with support columns 9, and the upper end of the support column 9 is provided with a connecting cross bar 5. The lower end of the right support column 9 is fixedly connected with the first buffer seat 6 by a spring 8, and the left side support column 9 lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com