Track gap adjustment mechanism and vehicle

A track gap and adjustment mechanism technology, which is applied to railway car body parts, transportation and packaging, etc., can solve the problems of hidden safety hazards in platform gaps, difficulty in adjustment, inflexible mechanisms, etc., achieve dynamic coverage, ensure track smoothness, and solve potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

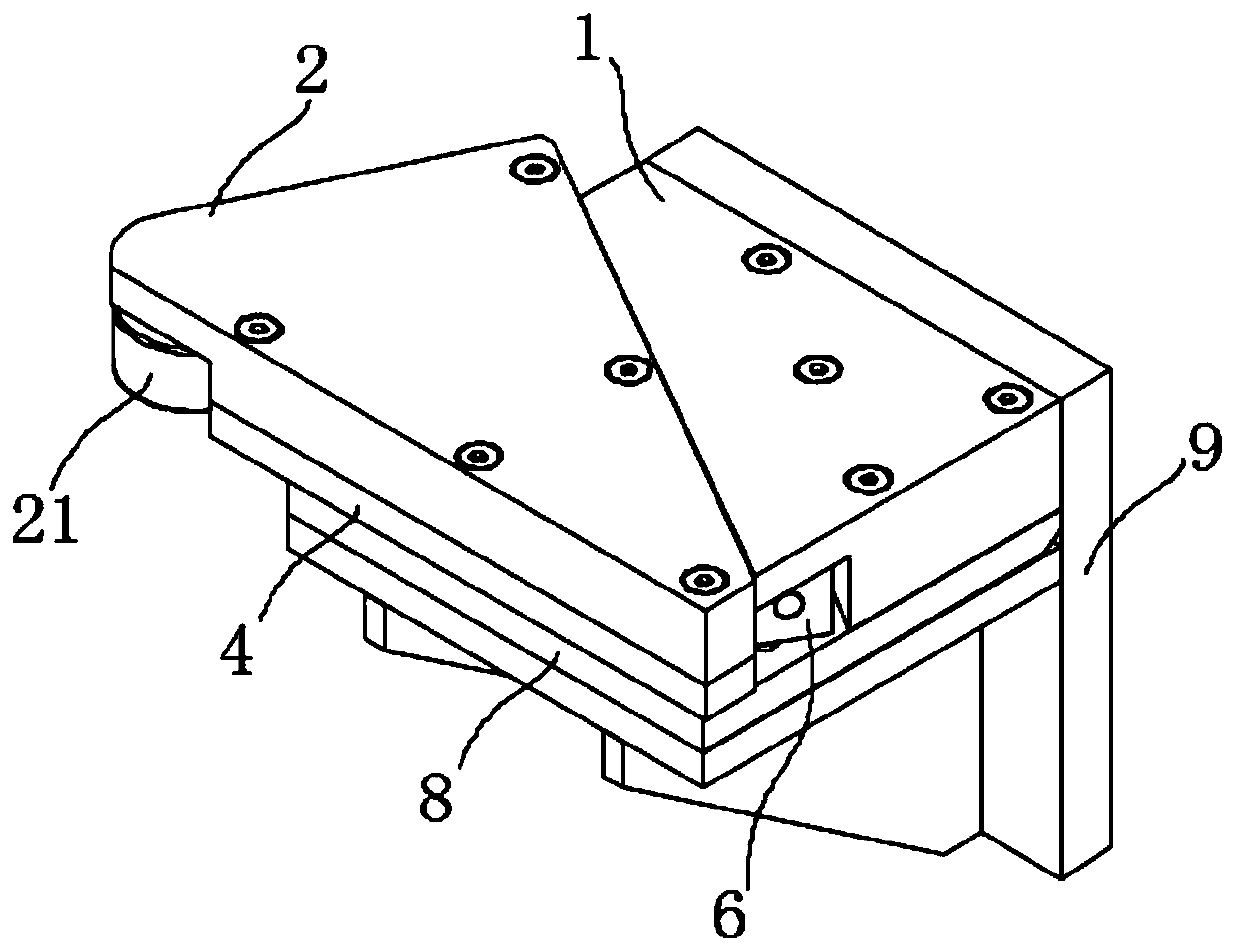

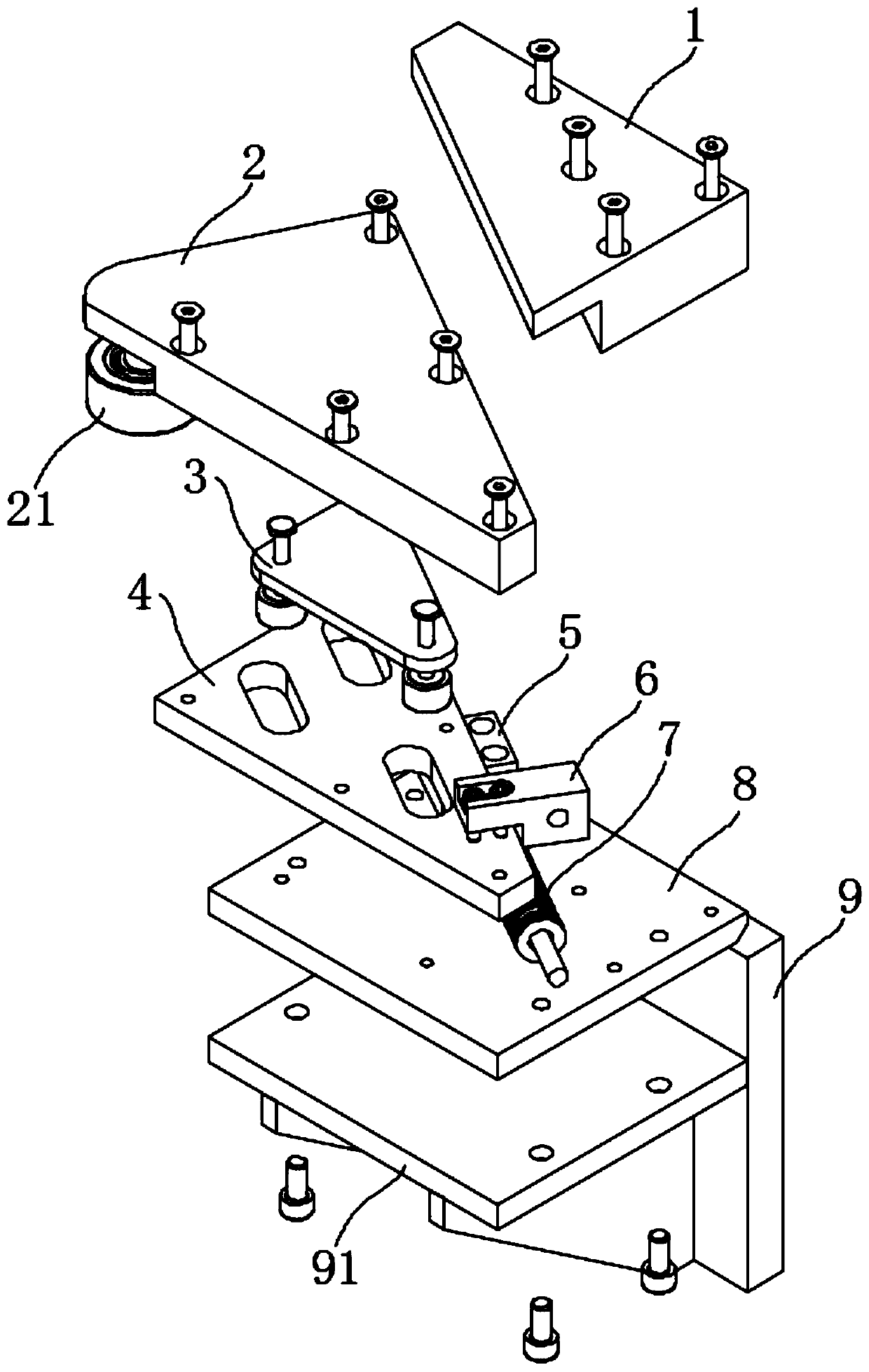

[0034] like figure 1 and figure 2 As shown, the track gap adjustment mechanism in this embodiment includes a linear motion mechanism 306, a driven mechanism 307 and a power mechanism. The power mechanism is installed inside or outside the track gap adjustment mechanism, and the power mechanism drives the linear motion mechanism 306 to drive the driven mechanism 307. Synchronized forward and sideways movement.

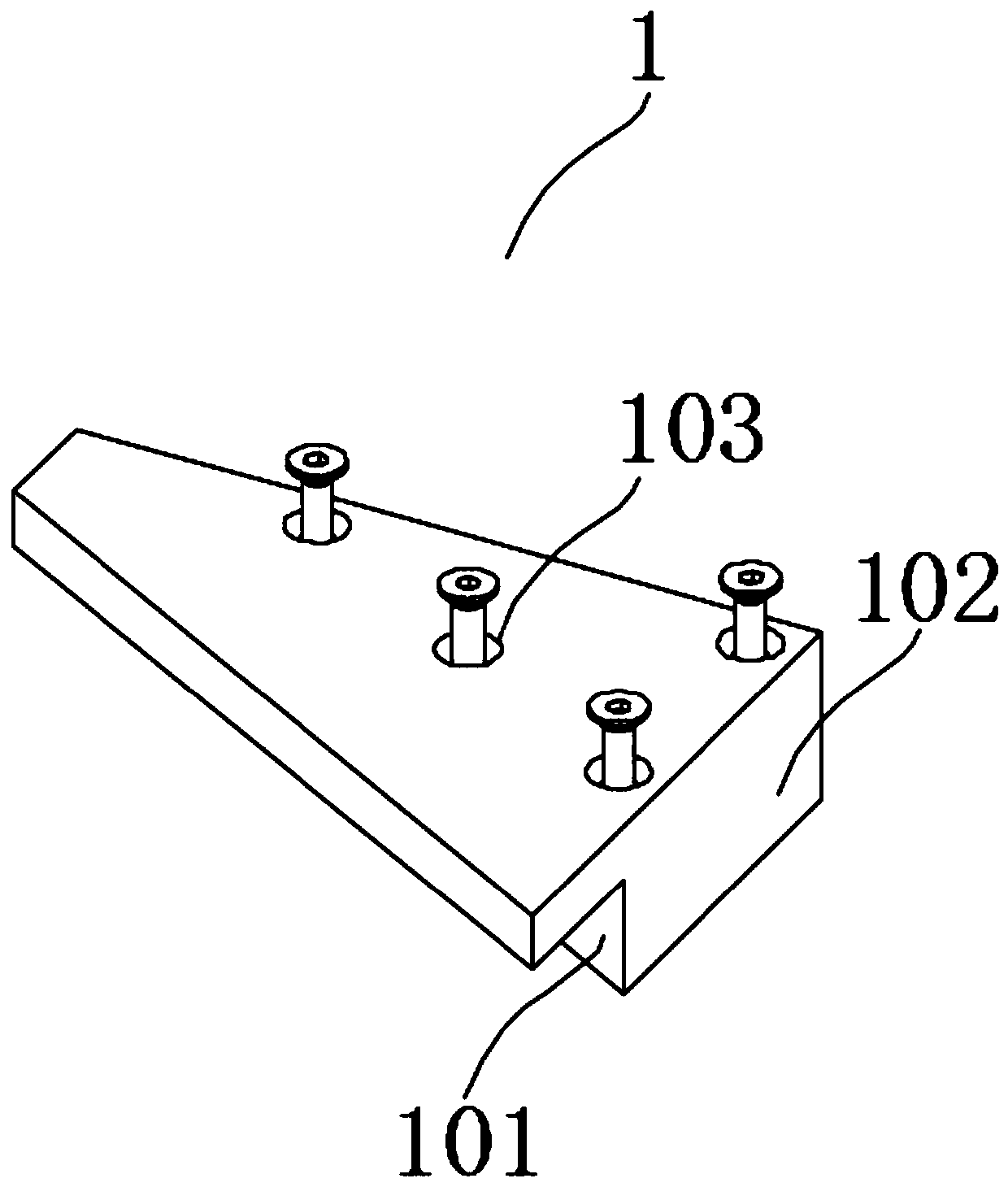

[0035] In this embodiment, the driven mechanism 307 includes image 3 As shown in the fixed cover 1, the fixed cover 1 includes a cover body 102. In this embodiment, the front of the cover body 102 is approximately trapezoidal. The side end is the short side end, and the side surface is an inclined surface. An L-shaped cover plate groove 101 is opened on the inclined surface of the cover plate main body 102. Further preferably, for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com