Tire

A tire and tire circumferential technology, applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of reduced rigidity of the land part, reduced handling stability on dry roads, and reduced ground contact area, etc. To achieve the effect of suppressing the significant reduction and suppressing the handling stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

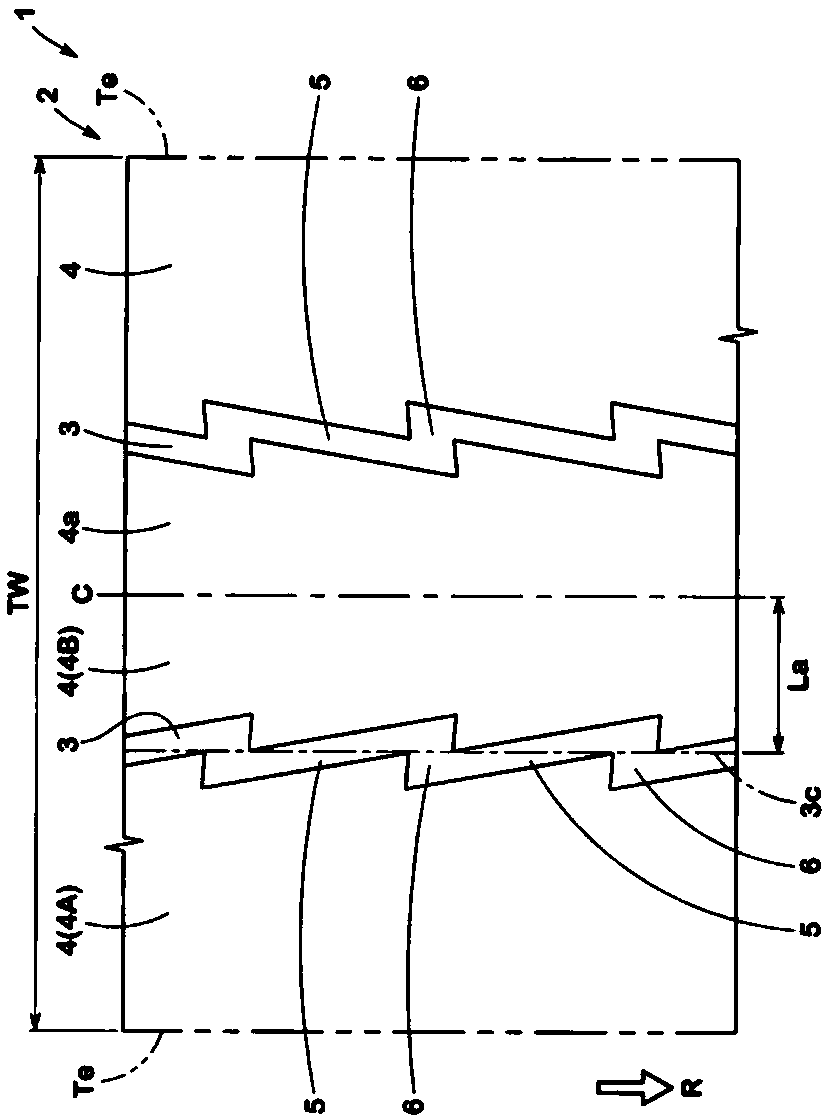

[0065] Based on the specifications in Table 1, prototypes with figure 1 The pneumatic tires with the size of 245 / 40R18 in the basic pattern were tested for the handling stability and drainage performance of each trial tire. The main common specifications and test methods of each trial tire are as follows.

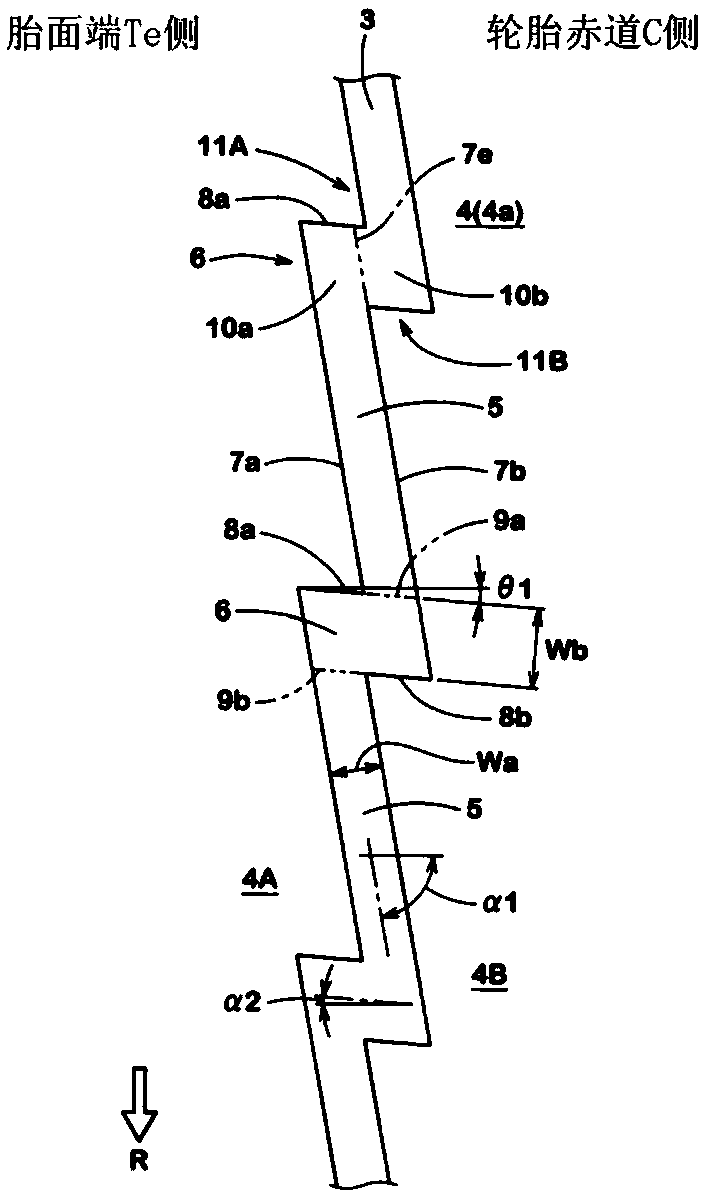

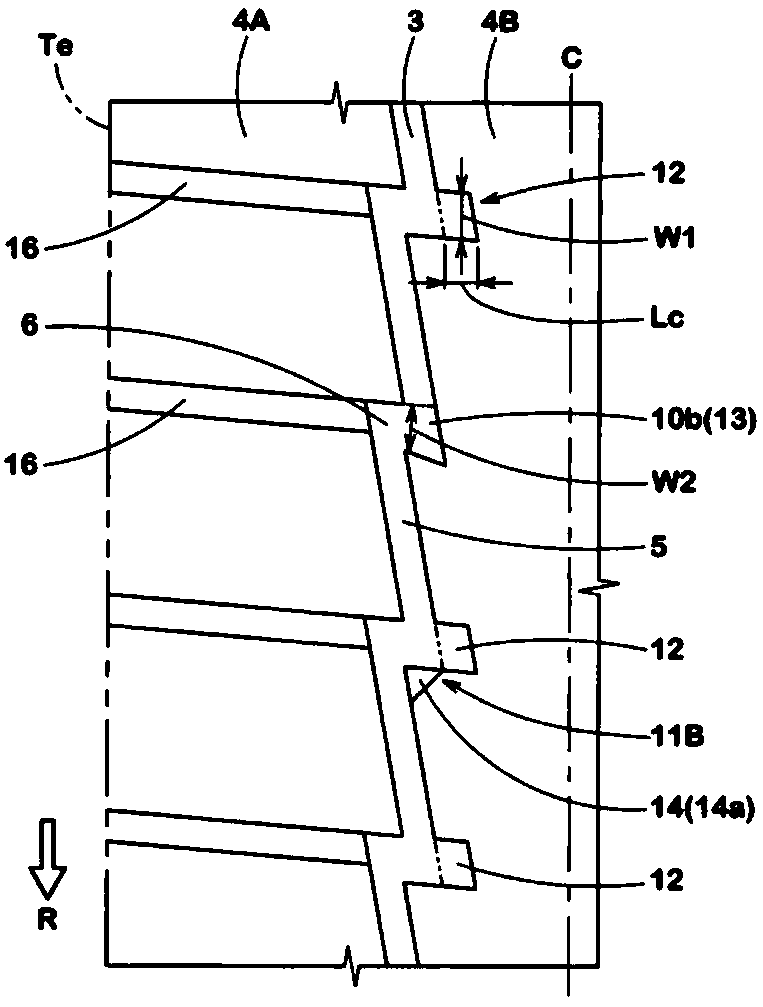

[0066] Groove depth of the main groove (inclined elements and axial elements): 6mm.

[0067] The maximum width Wa of the inclined element: 10mm (3.2% of the tread width)

[0068] Angle θ1 of the inclined element: 80°.

[0069] "Parallel to the trench wall of the rear grounding side" in Table 1 means that the edge of the trench wall of the first grounding side extends parallel to the edge of the trench wall of the rear grounding side.

[0070] "Opposite to the rear ground contact side groove wall" in Table 1 means that the bezel of the ground contact first side groove wall is inclined toward the rear ground contact side in the rotation direction R toward the tire equator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com