Equipment parameter inspection management system based on two-dimensional code recognition and working method thereof

A technology of equipment parameters and management systems, applied in inspection time patrols, devices and instruments for collaborative work, etc., which can solve problems such as difficult to supervise in place, too much data, and difficult to guarantee the authenticity of data.

Inactive Publication Date: 2018-11-20

张飞宇

View PDF3 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the process of operation and maintenance, manual inspection is currently carried out by manual recording, which usually has the following disadvantages: 1) low efficiency; 2) it is necessary to carry paper materials to the site for inspection and filling, and the data must be entered twice before it can be counted into the computer ; 3) There is a lot of long-term accumulated data, and the search remains unchanged; 4) Whether the personnel are actually in place, it is difficult to supervise; 5) The authenticity of the data is difficult to guarantee

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0025] The following is an explanation based on the inspection and trial report of UHV equipment in Taizhou.

[0026] 1. Basic conditions of the test

[0027] 1.1 Test name and product variety

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

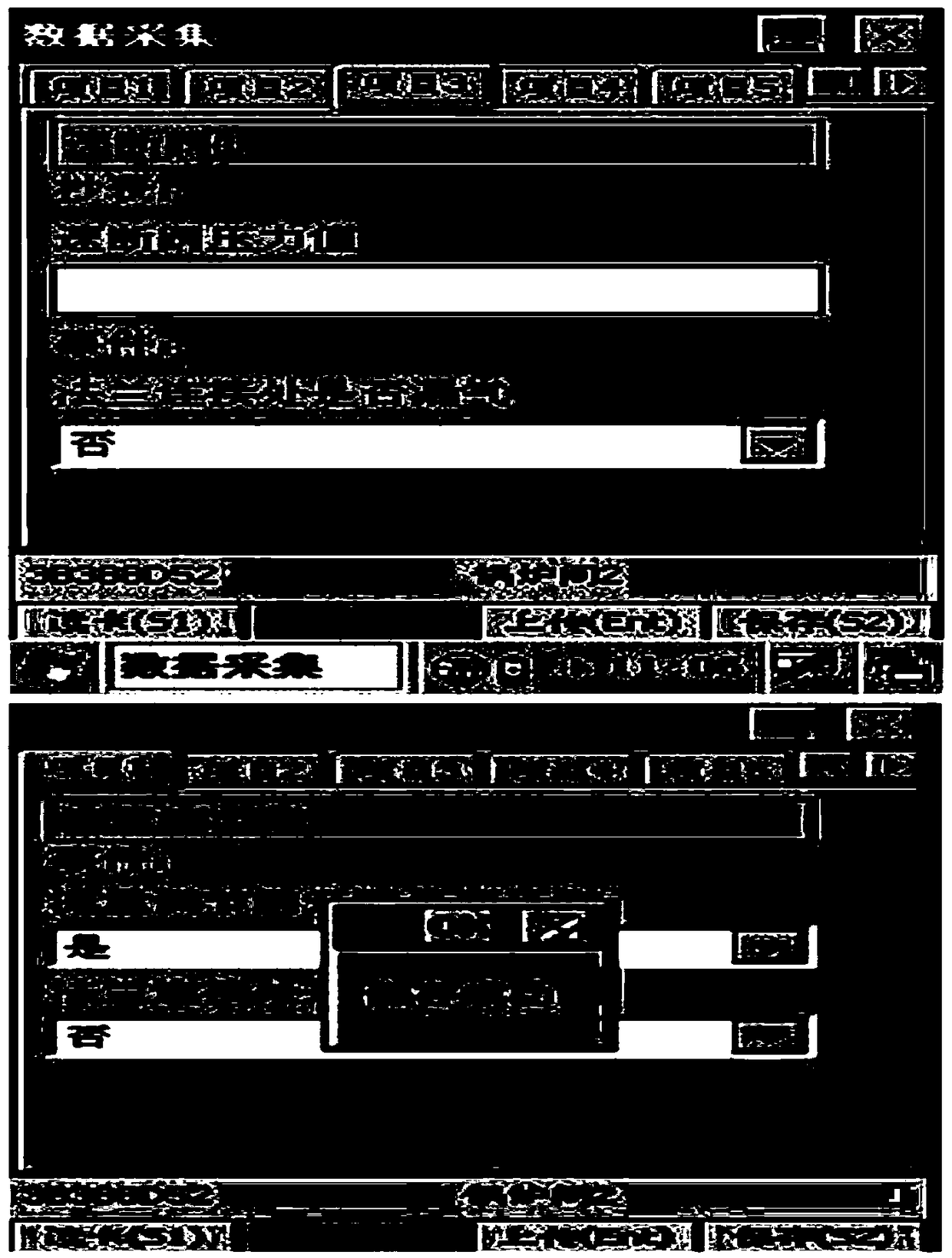

The invention belongs to the technical field of operation and maintenance application of power lines and specifically discloses an equipment parameter inspection management system based on two-dimensional code recognition. The system comprises RFID tags, a plurality of inspection item modules, a post inspection planning module, a computer, a daily inspection task module, an inspection circuit planning module, an inspection record module, a handheld terminal module and a data reporting module arranged on to-be-inspected equipment. The system disclosed by the invention has the beneficial effectsthat 1) inspection required according to the plan is really and objectively ensured on time; 2) the field state and related data can be conveniently and really recorded and uploaded in real time or in non-real time; 3) the inspection data can be subjected to statistical analysis, so that the inspection result is utilized; 4) the archiving management of the equipment is performed; and 5) the datadoes not need to be recorded for the second time, office automatization can be realized, the in-place number of each shift, the missing inspection number and missing inspection rate are counted, and the operating state and data report of each equipment can be formed, so that the equipment defects are conveniently analyzed by utilizing the data.

Description

technical field [0001] The invention belongs to the technical field of power line operation and maintenance applications, and in particular relates to an equipment parameter inspection management system based on two-dimensional code identification and a working method thereof. Background technique [0002] In the process of operation and maintenance, manual inspection is currently carried out by manual recording, which usually has the following disadvantages: 1) low efficiency; 2) it is necessary to carry paper materials to the site for inspection and filling, and the data must be entered twice before it can be counted into the computer ; 3) There is a lot of long-term accumulated data, and the search remains unchanged; 4) Whether the personnel are actually in place, it is difficult to supervise; 5) The authenticity of the data is difficult to guarantee. [0003] Therefore, based on the above problems, the present invention provides an equipment parameter inspection manageme...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G07C1/20G06K17/00G06Q10/00

CPCG06K17/0022G06Q10/20G07C1/20

Inventor 张飞宇张郭晶黄麒睿赵宏飞王鹏飞

Owner 张飞宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com