Connecting piece for making wire tightener connected with stay wire rod

A technology of connectors and wire tensioners, applied in the direction of transmission elements or pulley ropes or cables, textile cables, building types, etc., can solve problems such as low work efficiency, time-consuming and labor-intensive, and affect construction efficiency, and achieve installation and disassembly Convenient operation, convenient connection and disassembly, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be clearly and completely described below. Obviously, the described embodiments are part of the embodiments of the present application, rather than Full examples. Based on the embodiments in the present application, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present application.

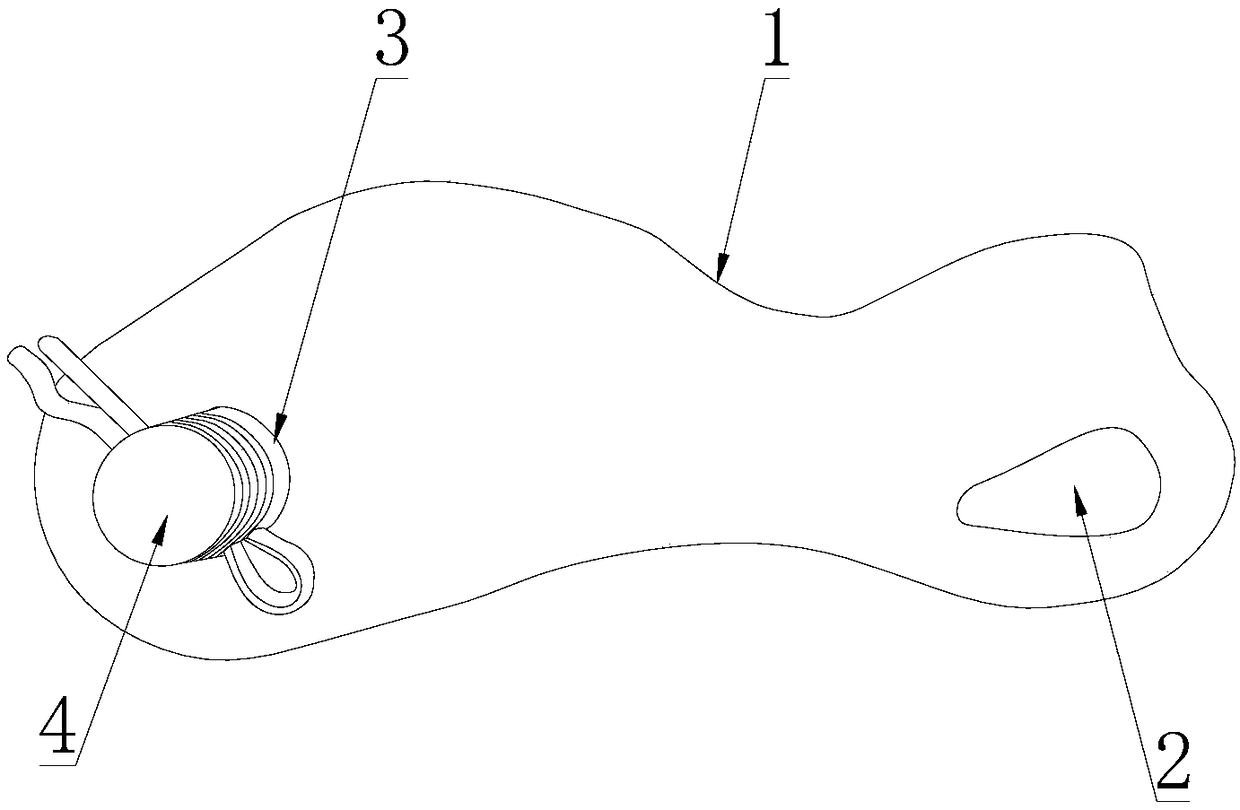

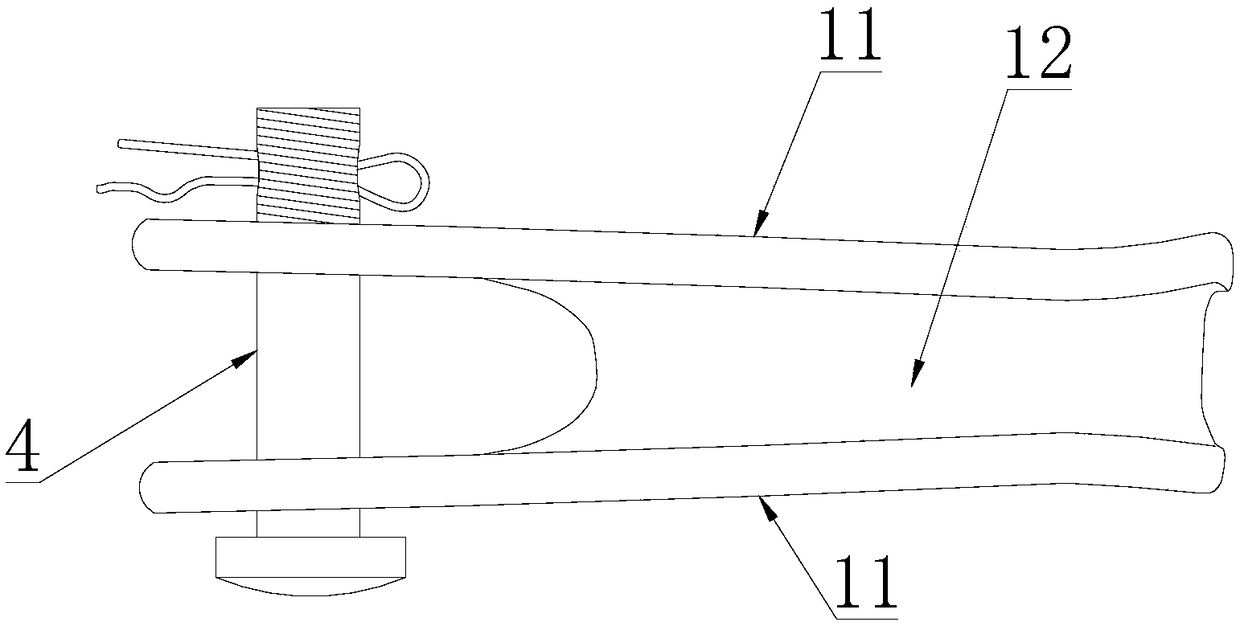

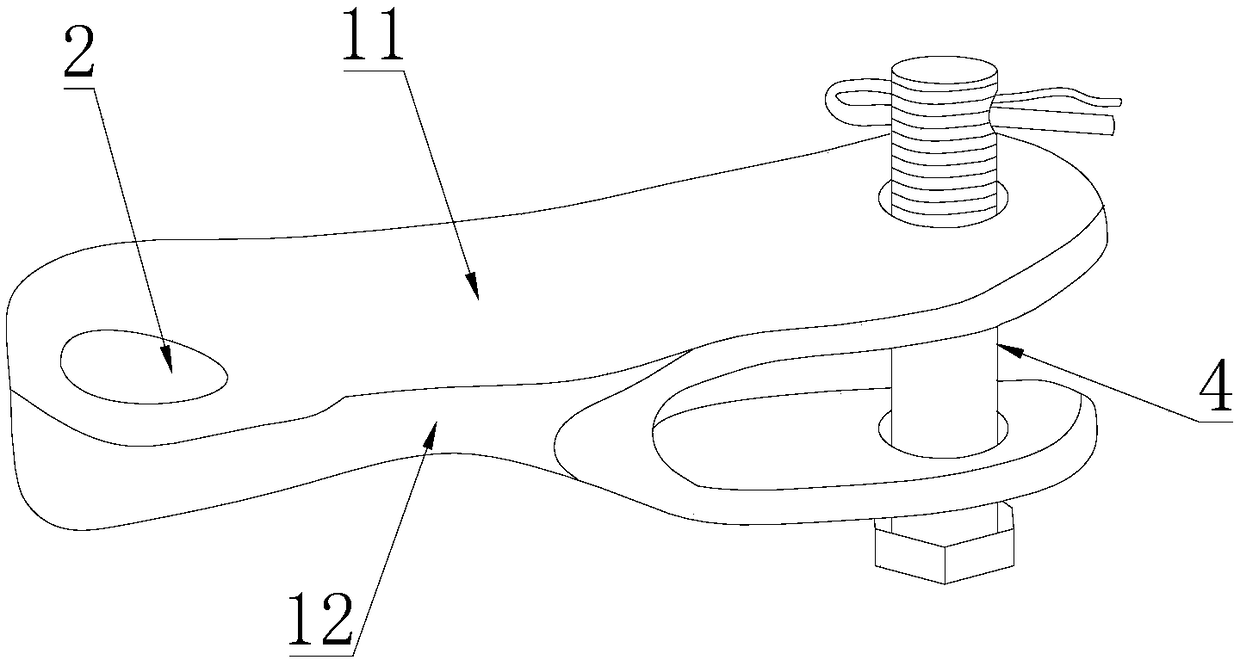

[0025] Such as Figure 1 to Figure 3 As shown, the present application provides a connecting piece for connecting the wire tensioner 6 and the wire rod 7, including a pin 4 and a trough-shaped body 1, the trough-shaped body 1 includes two side plates 11 arranged oppositely and connected to the The back plate 12 between the two side plates 11; at the first end of the grooved body 1, the two side plates 11 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap