Universal porous flexible accurate drilling template

A drilling template and flexible technology, which is applied in the field of aerospace electronic equipment assembly, can solve the problems of increasing the number of drilling templates, the huge tool recognition pressure of assembly workers, and waste, and achieves the effects of high precision, simple structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

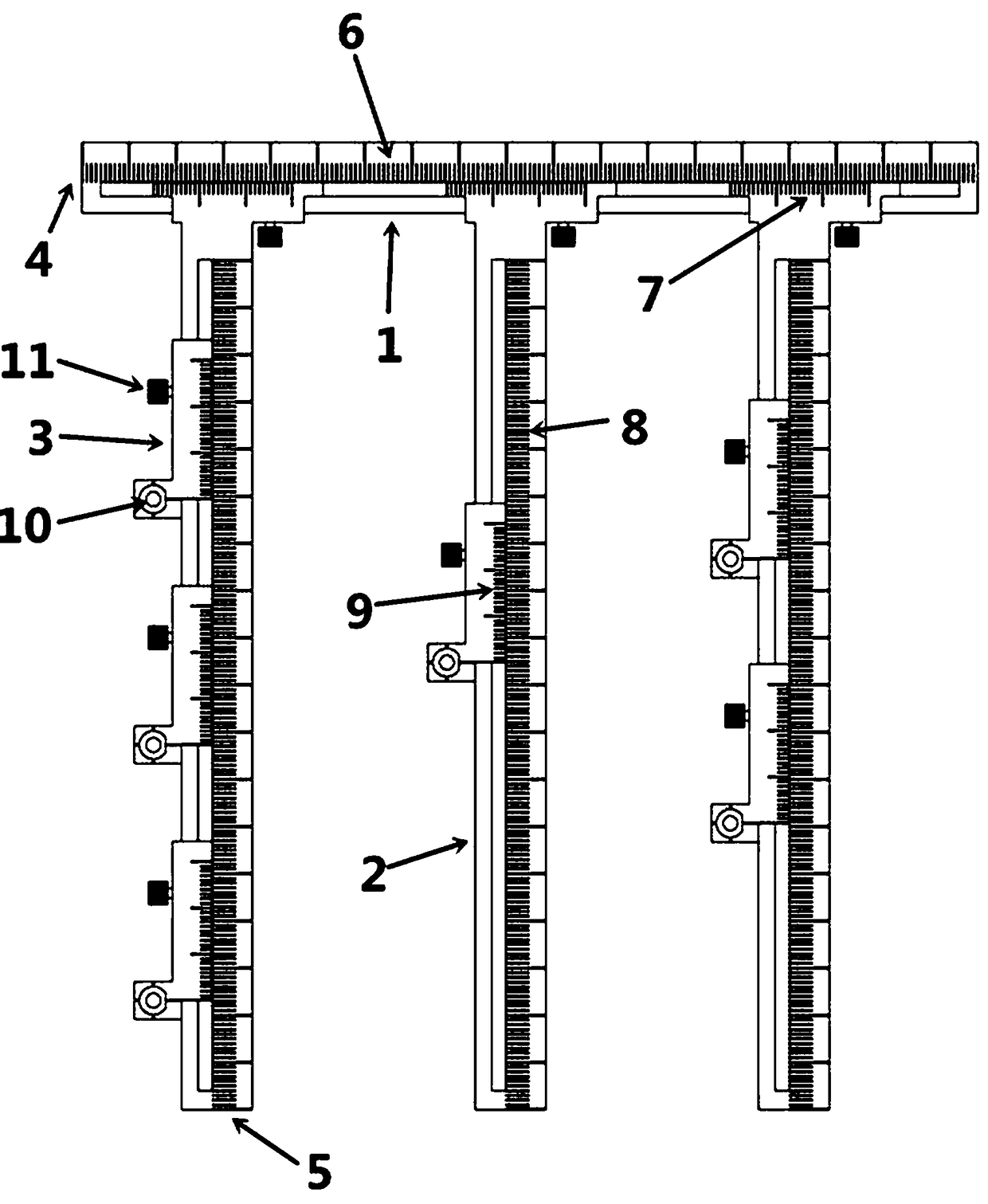

[0025] A general porous flexible precise drilling template, comprising a horizontal ruler 1, a vertical ruler 2, and a guide ruler 3, one end of the horizontal ruler 1 is provided with a lateral positioning surface 4, and the horizontal guide rail is arranged on the body of the horizontal ruler 1, the Several vertical rulers 2 are installed on the horizontal guide rail, and the longitudinal ruler 2 is slidingly connected with the horizontal ruler 1; Several guide rulers 3 are installed on the longitudinal guide rail, and the guide ruler 3 is slidingly connected with the vertical ruler 2; the guide ruler 3 is provided with a guide hole 10.

[0026]During the use of the present invention, according to the number of horizontal installation holes to be processed, a corresponding number of vertical rulers 2 are sleeved on the horizontal guide rails of the horizontal ruler 1; Establish the corresponding number of guide rulers 3; determine the exact position of the installation hole ...

Embodiment 2

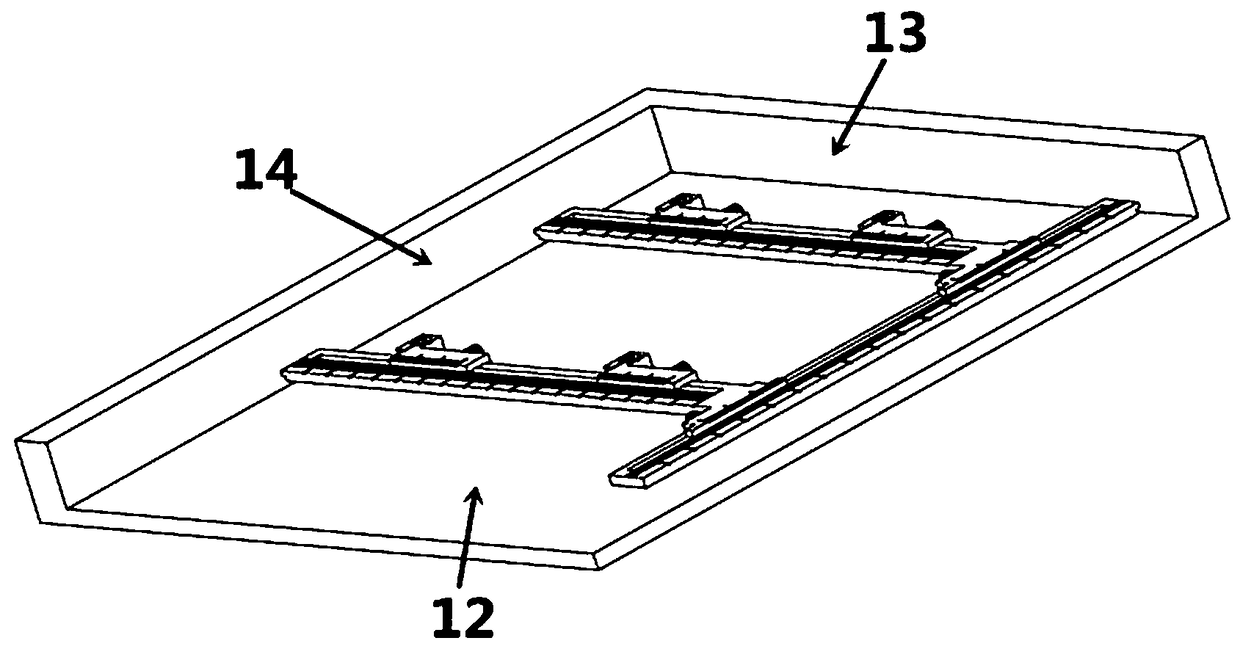

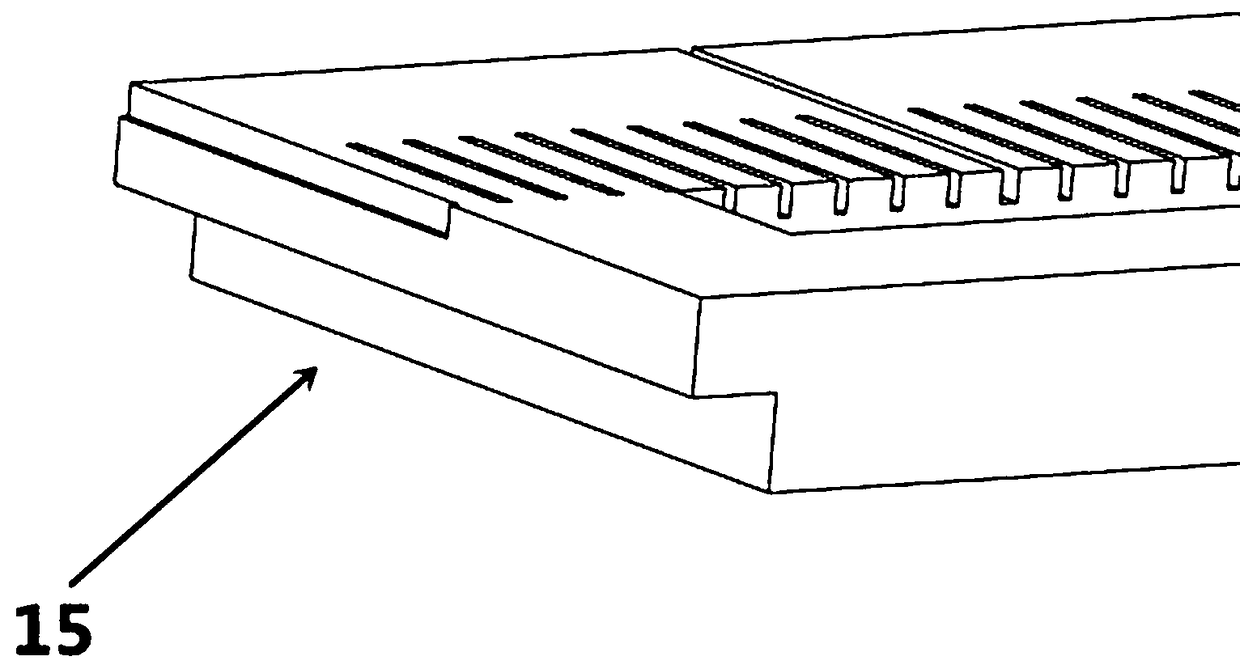

[0028] This embodiment is further optimized on the basis of embodiment 1, as image 3 As shown, the transverse positioning surface 4 and the longitudinal positioning surface 5 are provided with rounded steps. During the use of the present invention, the rounded steps are provided on the transverse positioning surface 4 and the longitudinal positioning surface 5 so that the present invention avoids the rounded corners of the reference plane on the workpiece and the drilling surface 12 during use, and avoids the occurrence of workpieces and the present invention. Interference affects the positioning accuracy.

[0029] Other parts of this embodiment are the same as those of Embodiment 1 above, so details are not repeated here.

Embodiment 3

[0031] This embodiment is further optimized on the basis of embodiment 2, as figure 1 As shown, the horizontal reference scale 6 distributed along the horizontal direction is arranged on the body of the horizontal ruler 1; The longitudinal distribution is provided with a longitudinal reference scale 8; the guide ruler 3 chi body is provided with a longitudinal vernier scale 9 distributed along the longitudinal direction; It is on a straight line, and the zero scale line of the horizontal vernier scale 7 of the longitudinal ruler 2 is on a straight line in the longitudinal direction; it also includes a locking screw 11, and the guide ruler 3 is connected with the longitudinal ruler 3 through the locking screw 11, so The vertical ruler 3 is connected with the horizontal ruler 1 by locking screws 11.

[0032] The present invention is in use, according to the center of circle of each guide hole 10 and the zero scale line of the longitudinal vernier scale 9 of guide ruler 3 being ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com