Rotary driving structure for seat test stand

A rotary drive, test bench technology, applied in vibration testing, vehicle testing, machine/structural component testing, etc., can solve the problems of poor detection accuracy, inconvenient use, complex structure, etc., and achieve long service life and good application prospects. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

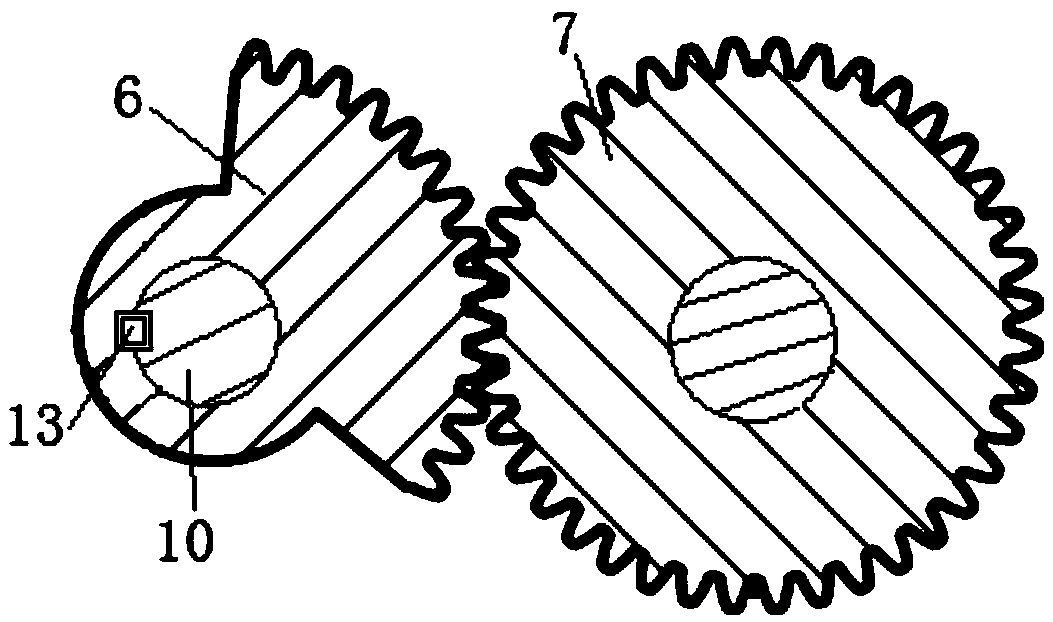

[0021] The seat test bench of the present invention uses a rotating drive structure, such as figure 1 As shown, it includes a sector tooth 6 arranged on the rotating shaft 10, and the sector tooth 6 is meshed with the drive gear 7 for transmission. The rotation driving device also includes a motor 8 arranged on one side of the support 1 , and the output shaft end of the motor 8 is connected with the driving gear 7 . In the process of realizing the rotation, the rotation is started by the motor 8, and the rotation of the drive gear 7 drives the sector teeth 6 engaged with it to rotate, thereby driving the ballast block 5 to rotate within the rotation range of the sector teeth 6.

[0022] In the present invention, if figure 1 As shown, the rotating shaft 10 is provided with a keyway 11, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com