Salt damage-proof filter screen

A filter and salt-prevention technology, applied in the direction of filtration separation, membrane filter, layered products, etc., can solve the problems of increased resistance, high cost, single pore size, etc., to facilitate disassembly, prevent re-scattering, and reduce burden Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

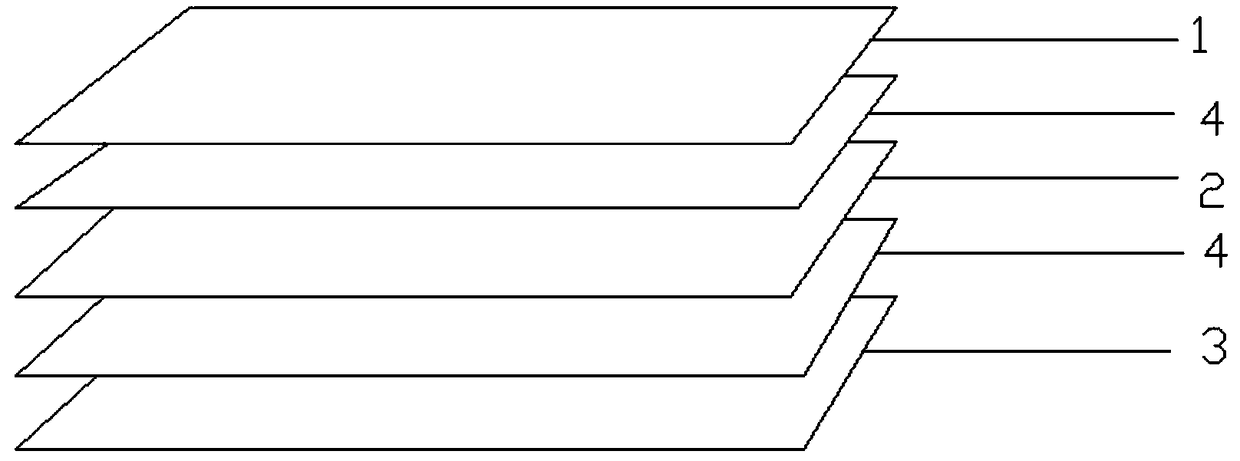

[0014] Such as figure 1 As shown, this embodiment discloses a filter screen for preventing salt damage, including a filter screen layer and a water-absorbing material layer. The filter screen layer has a first filter screen layer 1 and a second filter screen layer arranged sequentially from outside to inside. 2 and the third filter layer 3.

[0015] The above-mentioned first filter layer 1 is a low-density coarse filter. According to the size of the sea salt particles, preferably, the mesh diameter of the filter is 5um, which can prevent sea salt particles above 5um from entering the second filter layer. The first filter layer has a corrugated structure, which increases the filtering area.

[0016] The second filter layer 2 is a medium-density waterproof filter. According to the size of the sea salt particles, preferably, the filter mesh diameter is 1um, which can prevent sea salt particles above 1um from entering the first filter layer 1 The two sides of the second filter l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com