Method for arc extinguishing by DC load knife switch

A DC load and knife switch technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of short electrical life of DC load knife switches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

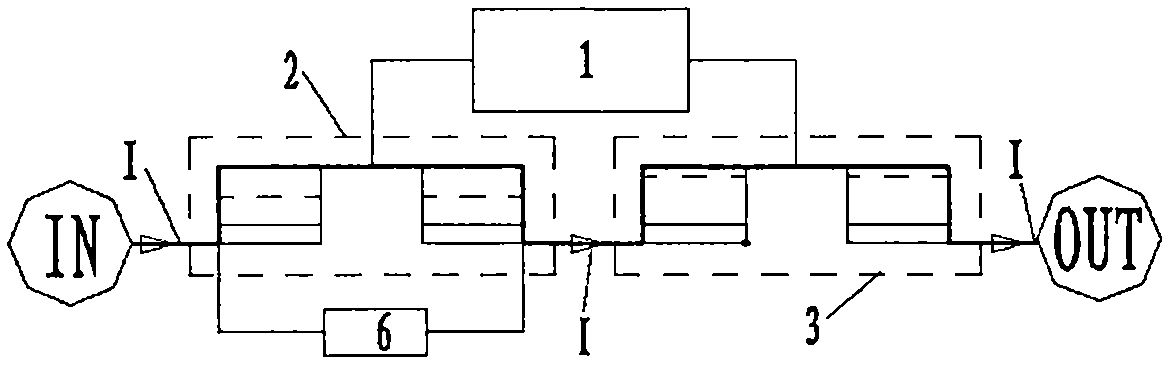

[0011] Such as figure 1 As shown, the load knife switch is connected in series to the DC system through the ports IN and OUT, where the port IN is connected to the positive pole of the DC power supply, and OUT is connected to the load. The first group of mechanical knife switches to be broken is connected in parallel with component 6, and then connected in series with the second group of mechanical knife switches to be broken. The connection of component 6 also has a direction, wherein the + terminal should be connected to the positive pole of the power supply, and the - terminal should be connected to the fixed knives connected to the 1st and 2nd sets.

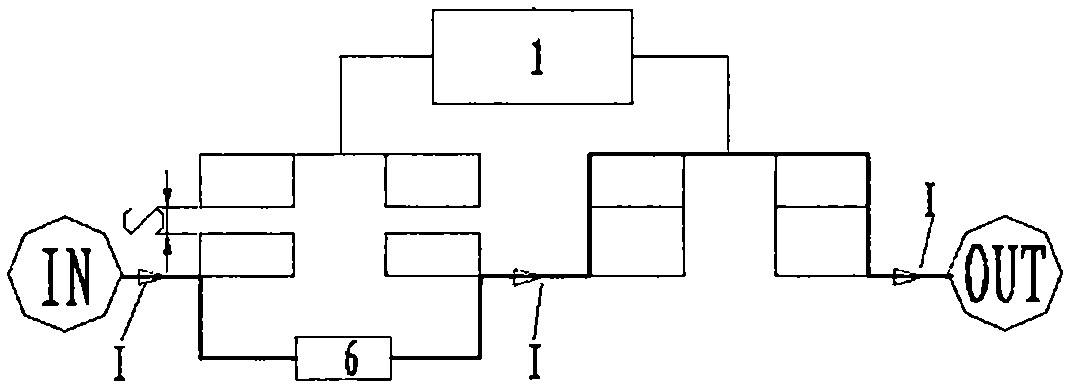

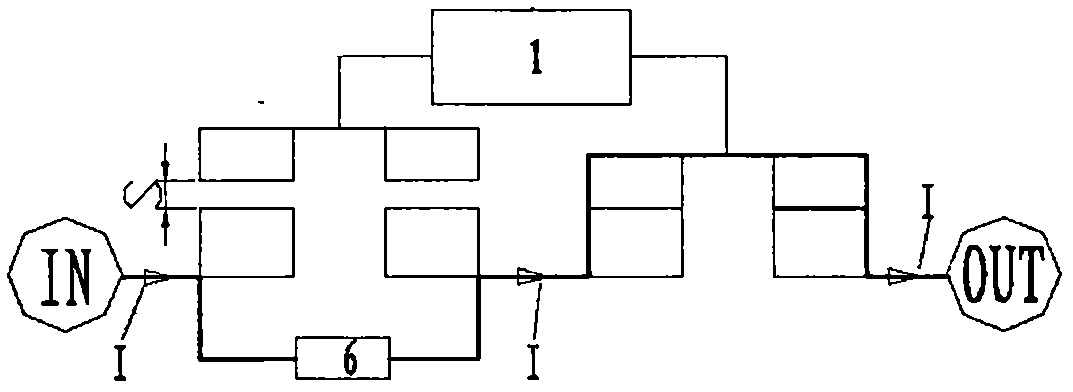

[0012] There is a time difference between group 1 and group 2 of the mechanical knife switch when breaking. This time difference is produced by mechanical design. The two sets of fixed knives of the load knife switch can be designed to have different heights to form a time difference, see figure 2 . It is also possible t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com