Multi-cutter farmland plow and operation method

A cutting tool and arable land technology, which is applied to plows, agricultural machinery and implements, applications, etc., can solve the problems of adjusting the angle of the cutting tool and the lack of data of the cutting tool when plowing cannot be done.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

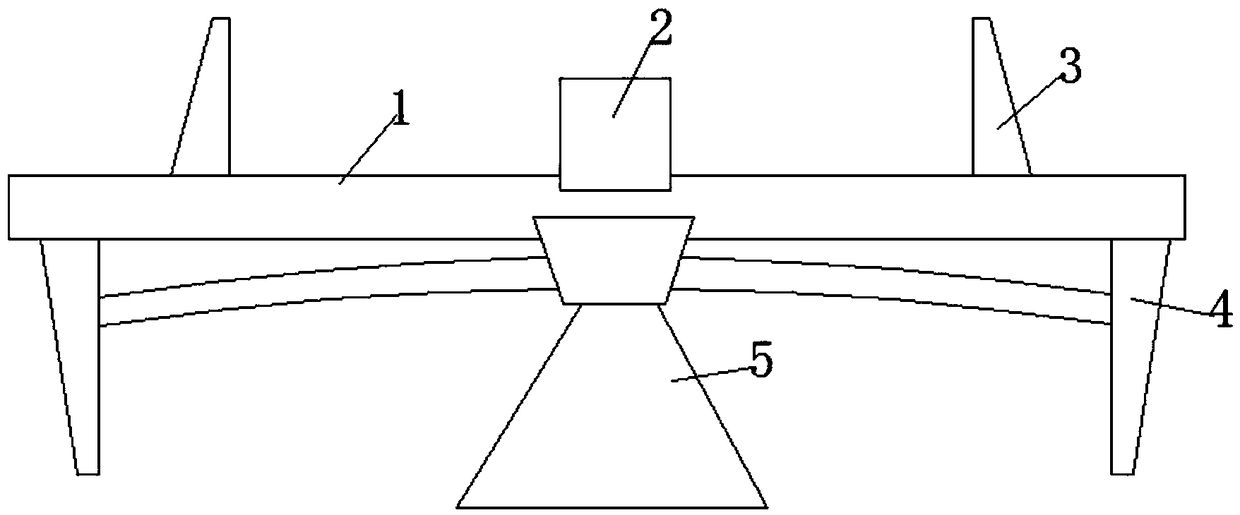

[0055] The multi-cutter plow of this embodiment 1 includes a frame 1, a first cutter assembly 4 is hinged at both ends of the lower side of the frame 1, and a second cutter assembly 4 is hinged at the middle of the lower side of the frame 1. Two cutter assemblies 5; a DSP controller 2 is fixed to the middle bolt on the upper side of the frame 1; the DSP controller 2 is used to control the inclination of the first cutter assembly 4 and the second cutter assembly 5 angle.

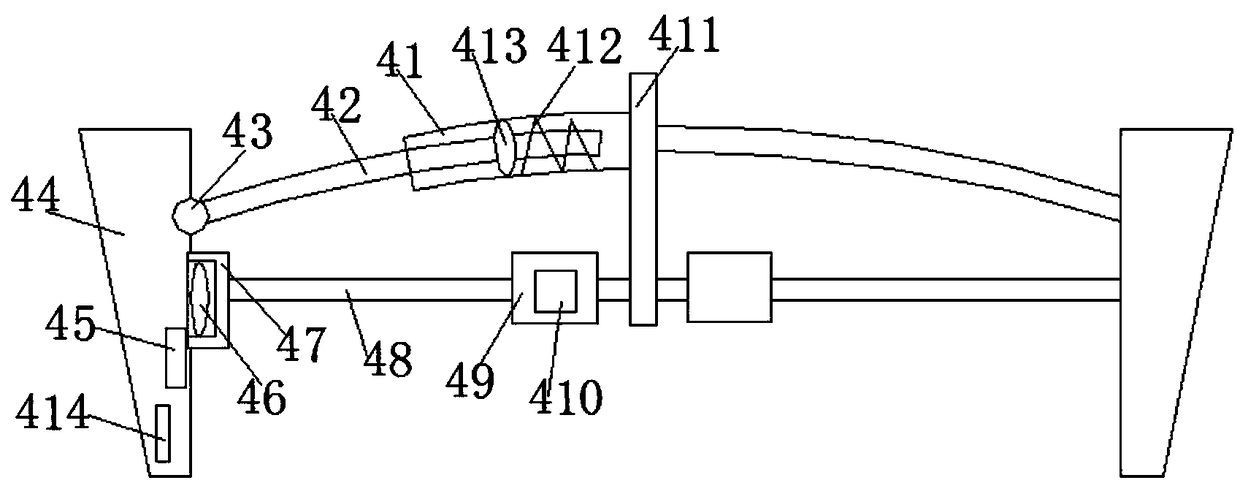

[0056] The first cutter assembly 4 includes a rectangular partition 411, a first telescopic tube 41 is fixed with bolts on the side wall of the top of the partition 411, and a circular ring is slid inside the first telescopic tube 41. arc-shaped first telescopic rod 42;

[0057] One end of the first telescopic rod 42 is hinged on the cutter 44 through the first hinge joint 43, and the other end is screwed with an elliptical retaining ring 413, and the retaining ring 413 slides on the first Inside the telesc...

Embodiment 2

[0078] Further, on the basis of embodiment 1:

[0079] The operation method of this embodiment 2 is used for the multi-cutter plow, comprising steps:

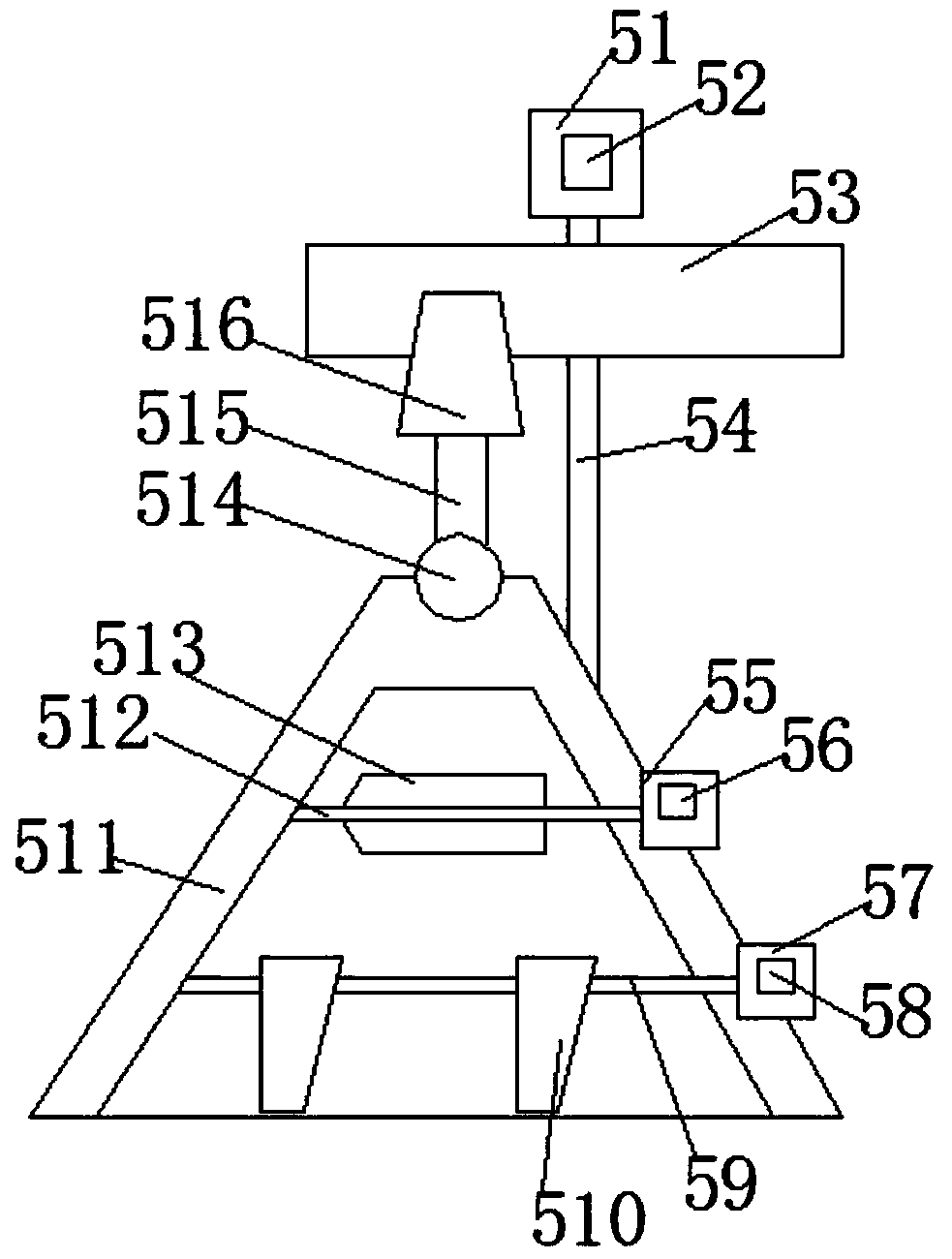

[0080] Step 1: Set the first target pressure value through the DSP controller 2, and set the first target angle to the first motor driver 410, and set the second target angle to the fourth motor driver 58;

[0081] Step 2: The multi-cutter plow starts to cultivate the land, the first pressure sensor 414 collects the pressure value and sends it to the DSP controller 2 for comparison, and the DSP controller 2 sends an adjustment command to the first pressure sensor 2 according to the comparison result. The motor driver 410, the fourth motor driver 58, the third motor driver 56 and the second motor driver 52;

[0082] Step 3: The first motor driver 410 , the fourth motor driver 58 , the third motor driver 56 and the second motor driver 52 respectively drive corresponding components for adjustment.

[0083] The multi-cutter plow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com