Automatic cable winding and arranging device

A technology of winding and winding device, which is applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of stable winding speed, uneven winding tightness, and cable wear, etc. To achieve the effect of maintaining stable winding speed, reducing labor intensity and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

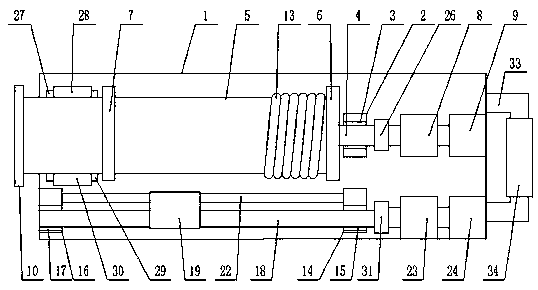

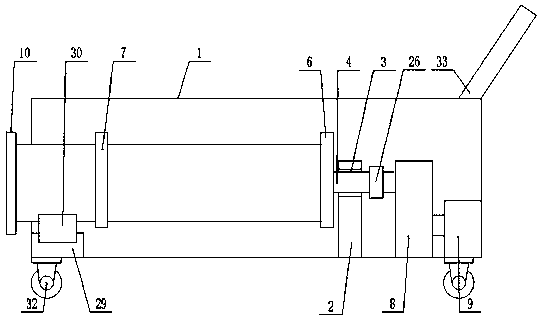

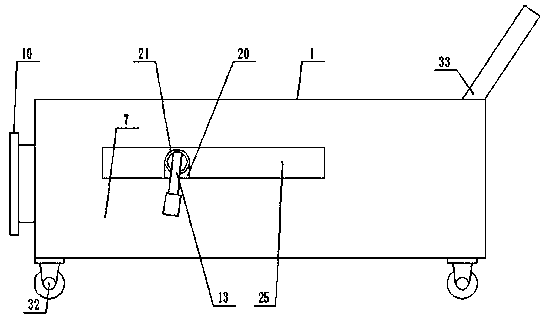

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, an automatic cable take-up and discharge device includes a housing 1, and the housing 1 is provided with a wire winding device and a wire management device. The wire winding device is fixed on the right end of the housing 1 by the first bearing 2. The first bearing 3 embedded in the first bearing seat 2, the roller set fixed in the housing 1 and at the opposite end to the first bearing seat 2, the rotating shaft 4 inserted in the first bearing 3, set in the The reel 5 on the rotating shaft 4 and located between the roller groups, the first baffle plate 6 sleeved on the reel 5 and located on the right side of the roller group, the second baffle plate 6 sleeved on the reel 5 and located on the left side of the first bearing seat 2 The baffle plate 7, the first reducer 8 located on the right side of the first bearing seat 2 and connected to the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com