An intelligent automatic dish delivery system

A vegetable conveying and intelligent technology, applied in mechanical conveyors, household utensils, table utensils, etc., can solve the problems of low degree of automation, high labor intensity, low efficiency, etc., and achieve the effect of reducing labor intensity, reducing overhead, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

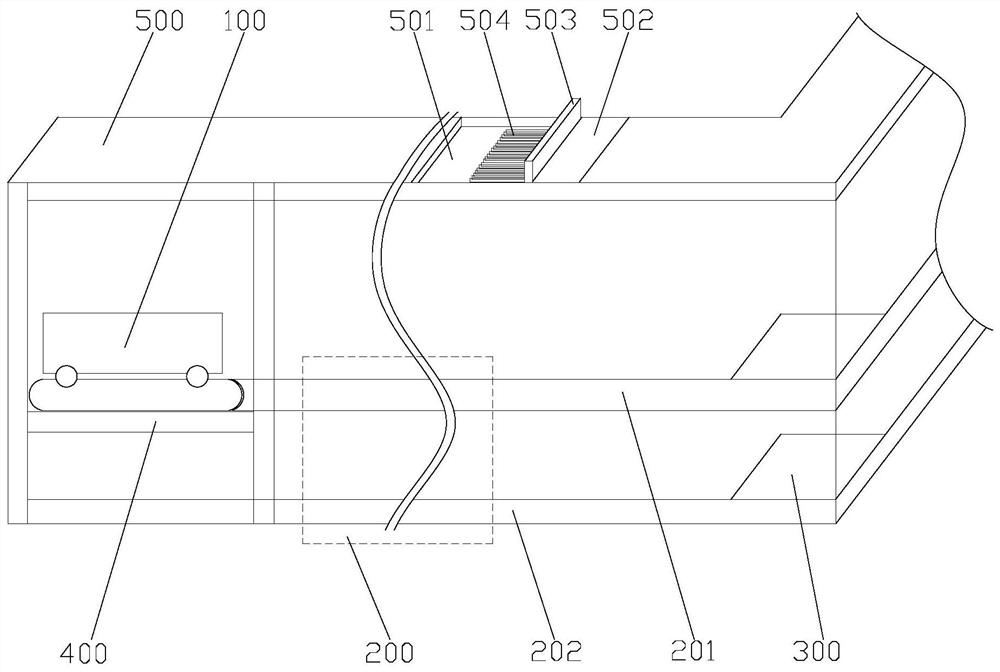

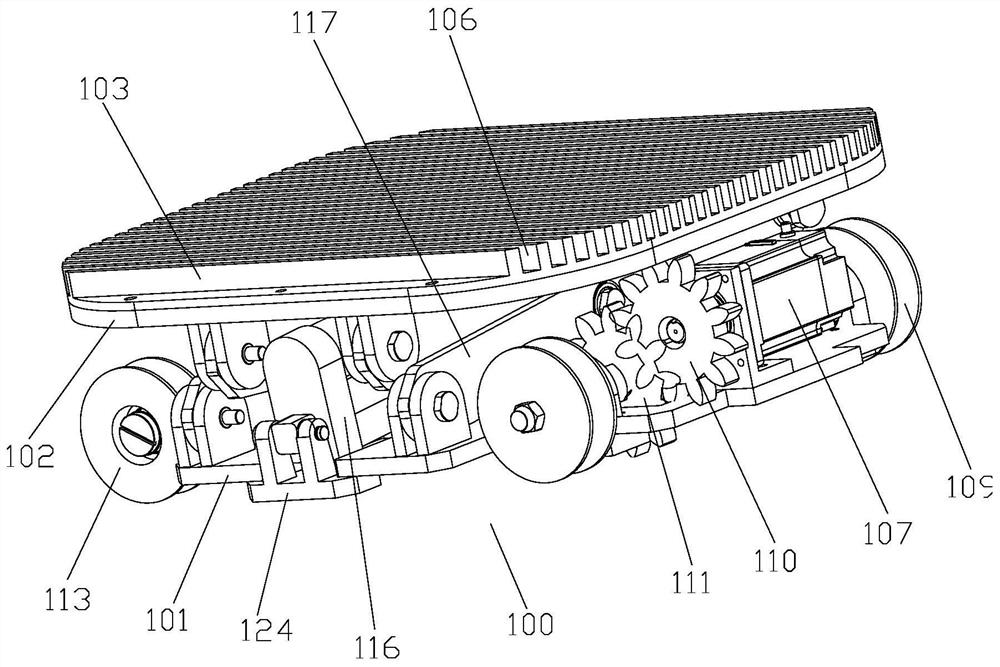

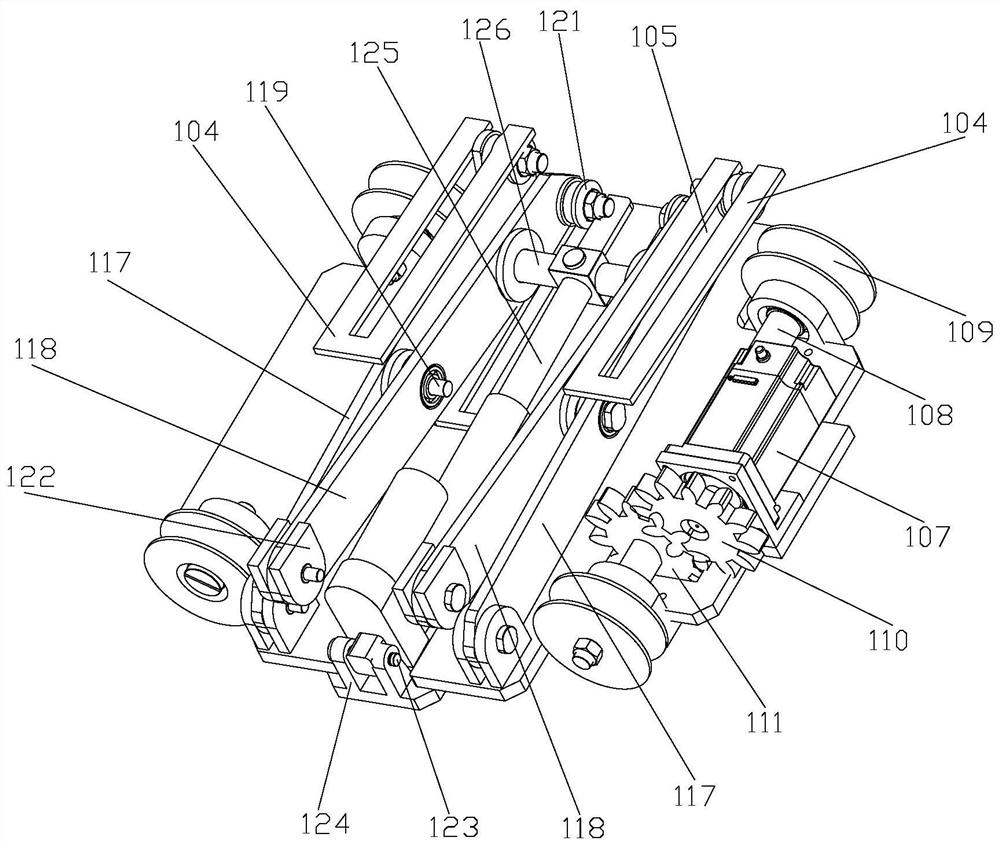

[0029] Such as Figures 1 to 6 As shown, the intelligent automatic vegetable delivery system of the embodiment of the present invention includes a control device, a conveying device and a vegetable conveying device, the vegetable conveying device is arranged on the conveying device to complete the vegetable conveying operation, and the control device is used to control the The vegetable conveying device is controlled during the vegetable conveying operation, and the conveying device includes a horizontal conveying device 200, a rotating device 300 and a lifting device 400, and the horizontal conveying device 200 includes a first set of horizontal conveying guide rails 201 and a second A group of horizontal conveying guide rails 202, the first group of horizontal conveying guide rails 201 is arranged above the second group of horizontal conveying guide rails 202, and the vegetable transfer device performs the vegetable transfer operation along the first group of horizontal conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com