Rotary heating type curing furnace for composite propeller

A technology of rotating heating and composite materials, applied in applications, household appliances, household components, etc., can solve problems such as temperature difference, large temperature difference, and affecting the quality of composite material propellers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

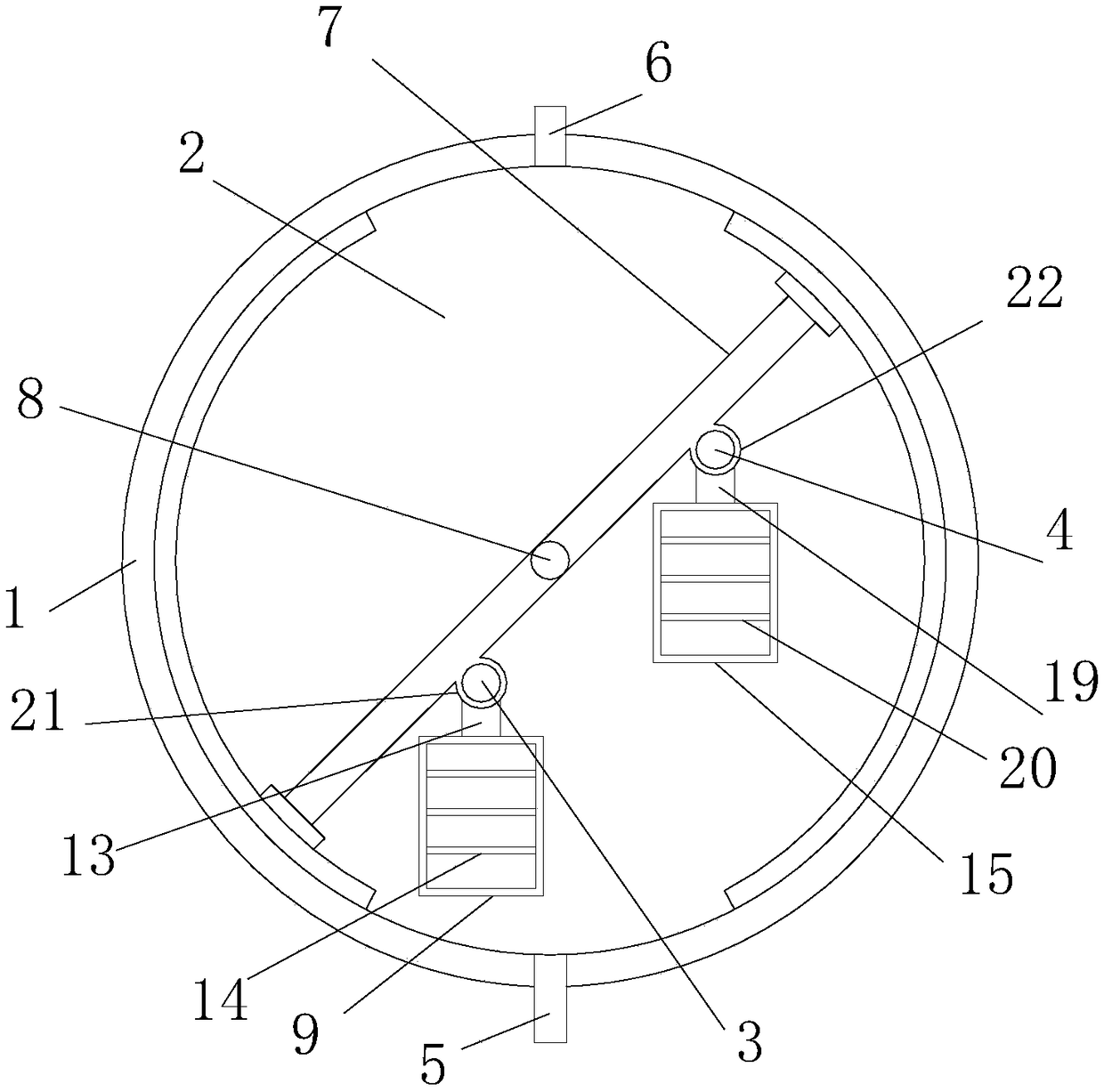

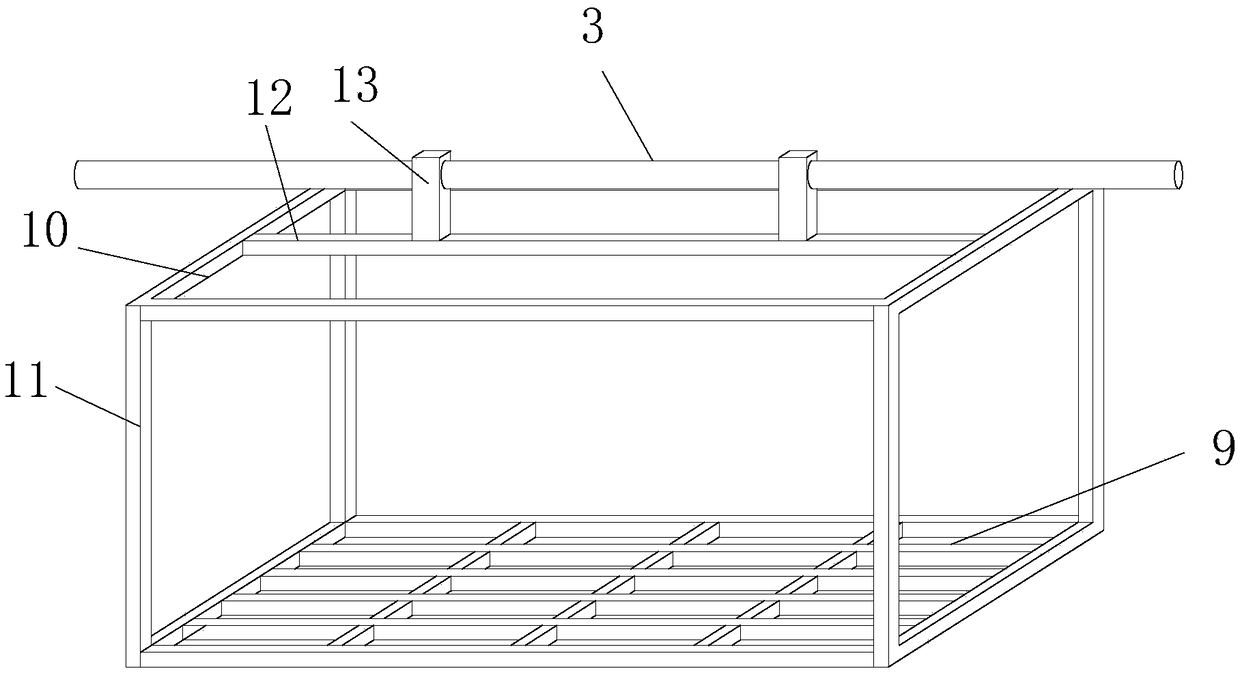

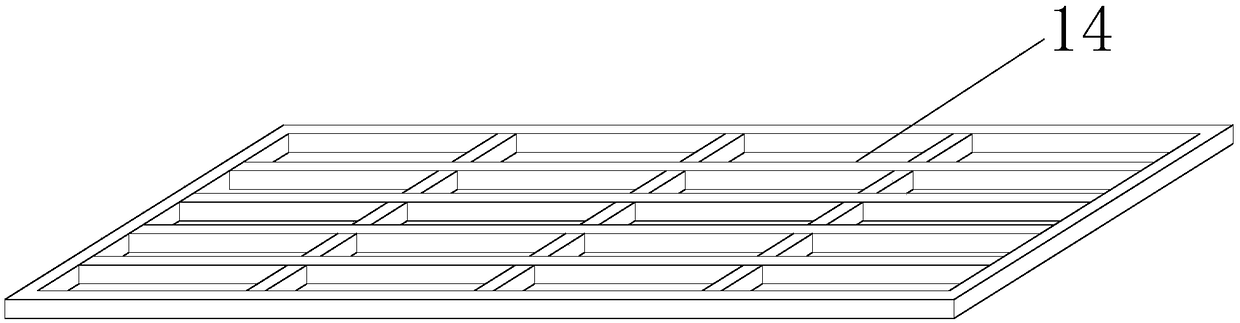

[0016] Such as Figure 1-Figure 5 as shown, figure 1 It is a structural schematic diagram of a rotary heating type curing furnace for a composite material propeller proposed by the present invention; figure 2 It is a structural schematic diagram of the first mold frame in a rotary heating type curing furnace for a composite material propeller proposed by the present invention; image 3 It is a structural schematic diagram of the second grid plate in a rotary heating type curing furnace for a composite material propeller proposed by the present invention; Figure 4 It is a structural schematic diagram of the second mold frame in a rotary heating type curing furnace for a composite material propeller proposed by the present invention; Figure 5 It is a structural schematic diagram of the fourth grid plate in a rotary heating type curing furnace for a composite material propeller proposed by the present invention.

[0017] refer to Figure 1-Figure 5 , a rotary heating type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com