Gear processing device

A processing device and gear technology, which is applied in gear tooth manufacturing devices, metal processing equipment, belts/chains/gears, etc., can solve the problems of reduced processing efficiency, high labor intensity, and low efficiency, so as to ensure grinding efficiency and improve The effect of grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

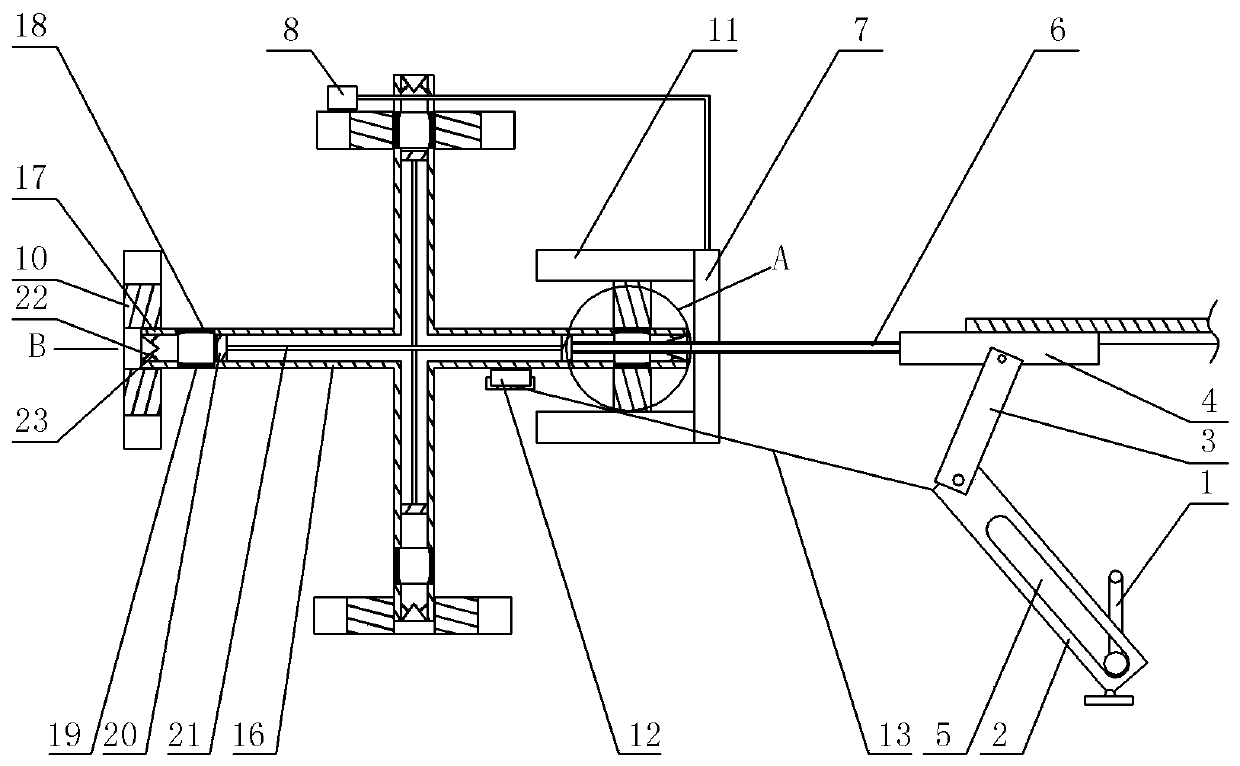

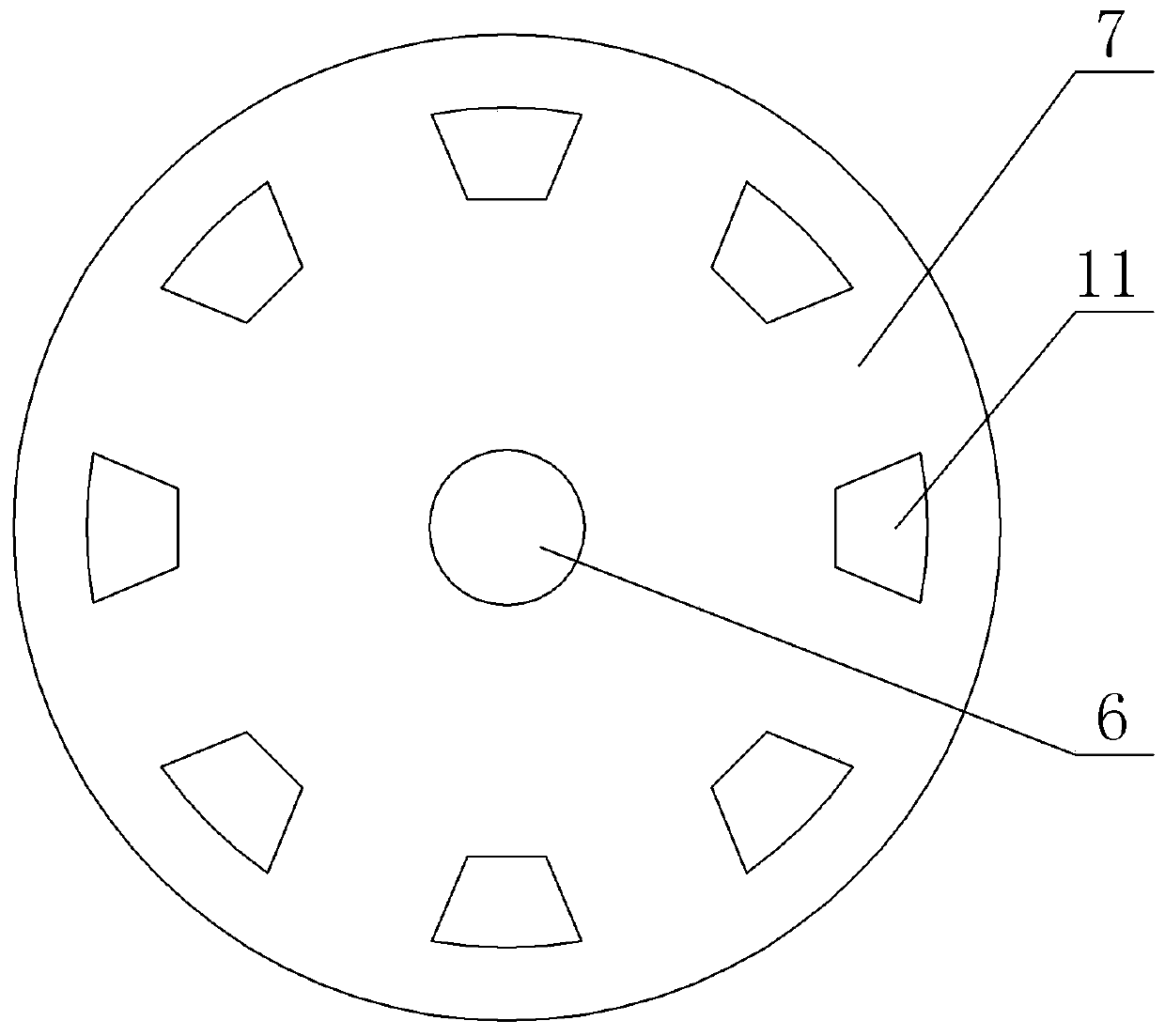

[0030] When the stepper motor rotates counterclockwise, it drives the toggle lever 1 to rotate to figure 1 When the position is shown, the toggle rod 1 drives the swing block 2 to swing to the leftmost, and now the swing block 2 pulls the slider 4 through the connecting block 3 to move to the leftmost, and the resisting plate 12 supports the rotating tube 16 at this time. In the process of slider 4 sliding to the left, it drives the unloading pipe 6 and the grinding disc 7 to move to the left. The burrs are polished.

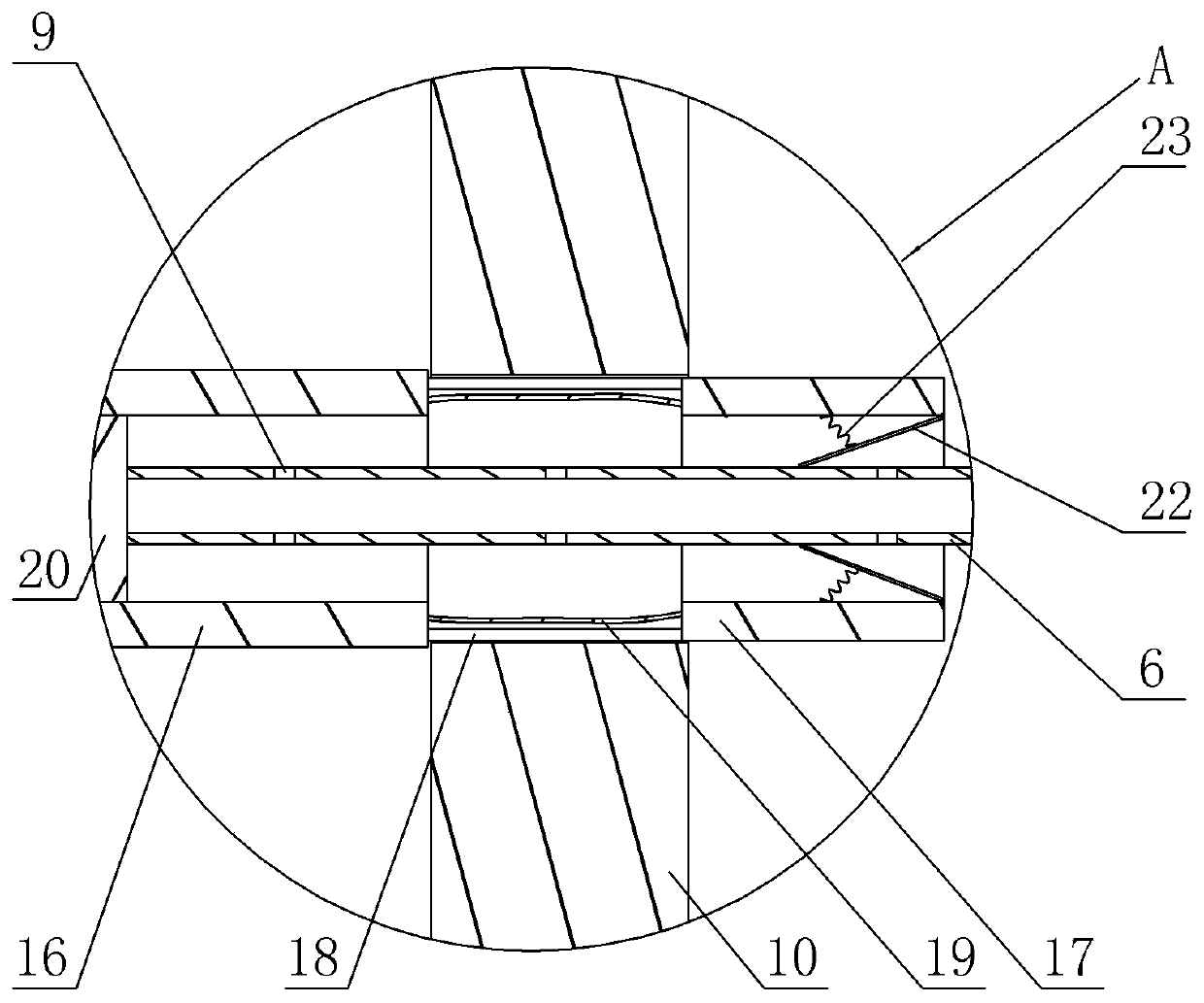

[0031] Such as figure 2 As shown, in the process that the discharge pipe 6 continues to move to the left, the discharge pipe 6 is in contact with the fan-shaped plate 22 at the right end of the support pipe 17, and the fan-shaped plate 22 is separated under the thrust of the discharge pipe 6, and the discharge pipe 6 enters In the support tube 17, the gas in the support tube 17 and the rotating tube 16 overflows from the discharge tube 6 through the pores 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com