Quadrupole permanent-magnet brush coreless motor rotor structure

A motor rotor and hollow cup technology, applied in the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve problems such as complex structure, low motor efficiency, magnetic flux leakage outside the casing, etc., and achieve winding structure Simple, simplified number of carbon brushes, low case magnetic flux leakage effect

Inactive Publication Date: 2018-10-30

重庆长基科技有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Most of the current permanent magnet brushed coreless motors have a two-pole structure (that is, a pair of magnetic steel), and it is clear that the power density of a four-pole (that is, two pairs of magnetic steel) or more poles is higher than that of a two-pole motor; at the same time , affected by the structure of the brushed hollow cup motor, the magnetic circuit of the two-pole motor is long, resulting in a more prominent phenomenon of magnetic flux leakage outside the casing. The existing solution is to use a thicker casing to prevent magnetic flux leakage, so the weight of the motor increases. Lightweight is contradictory; under som

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Example Embodiment

[0027] The present invention will be further described below in conjunction with the drawings and embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

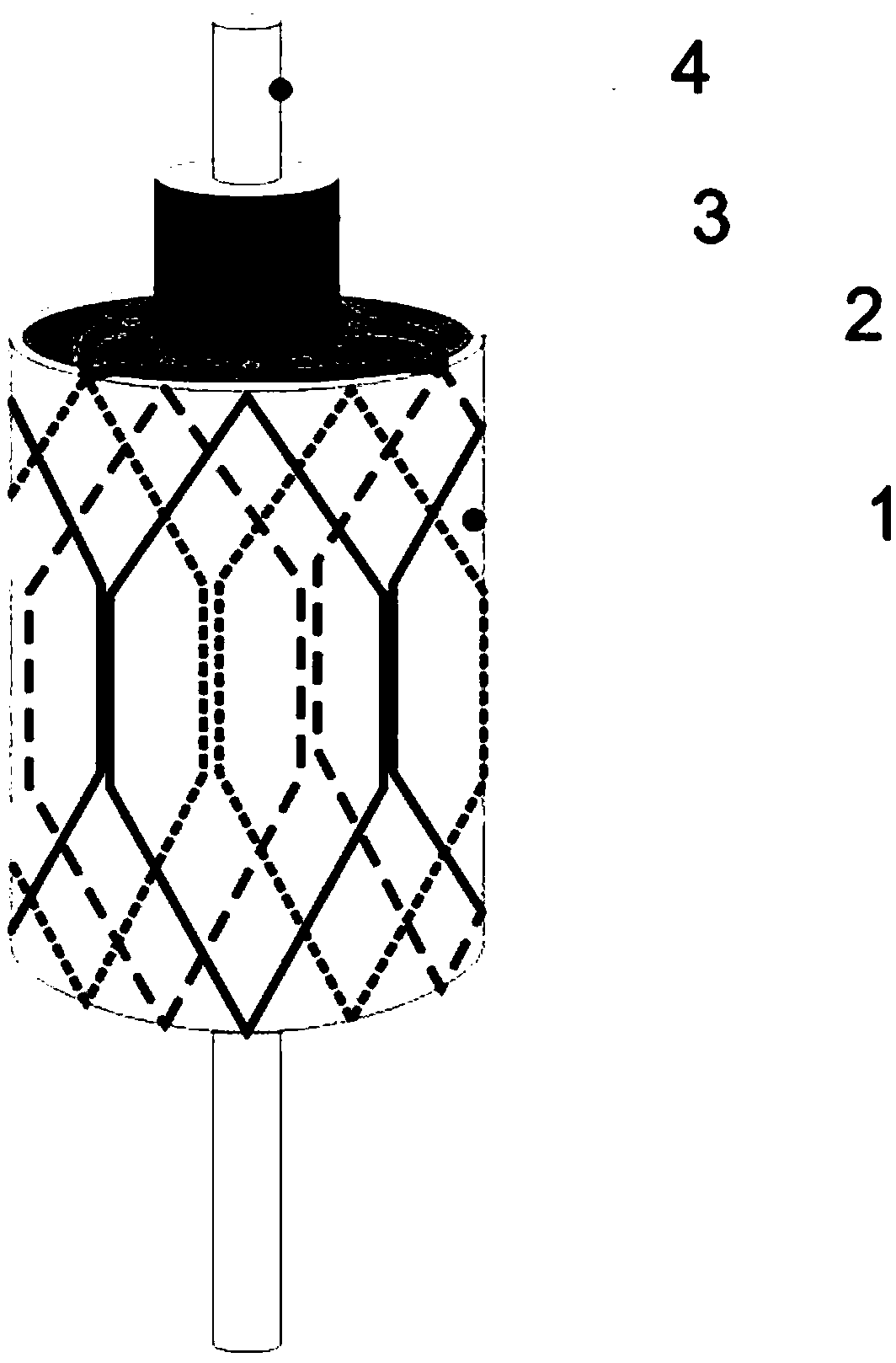

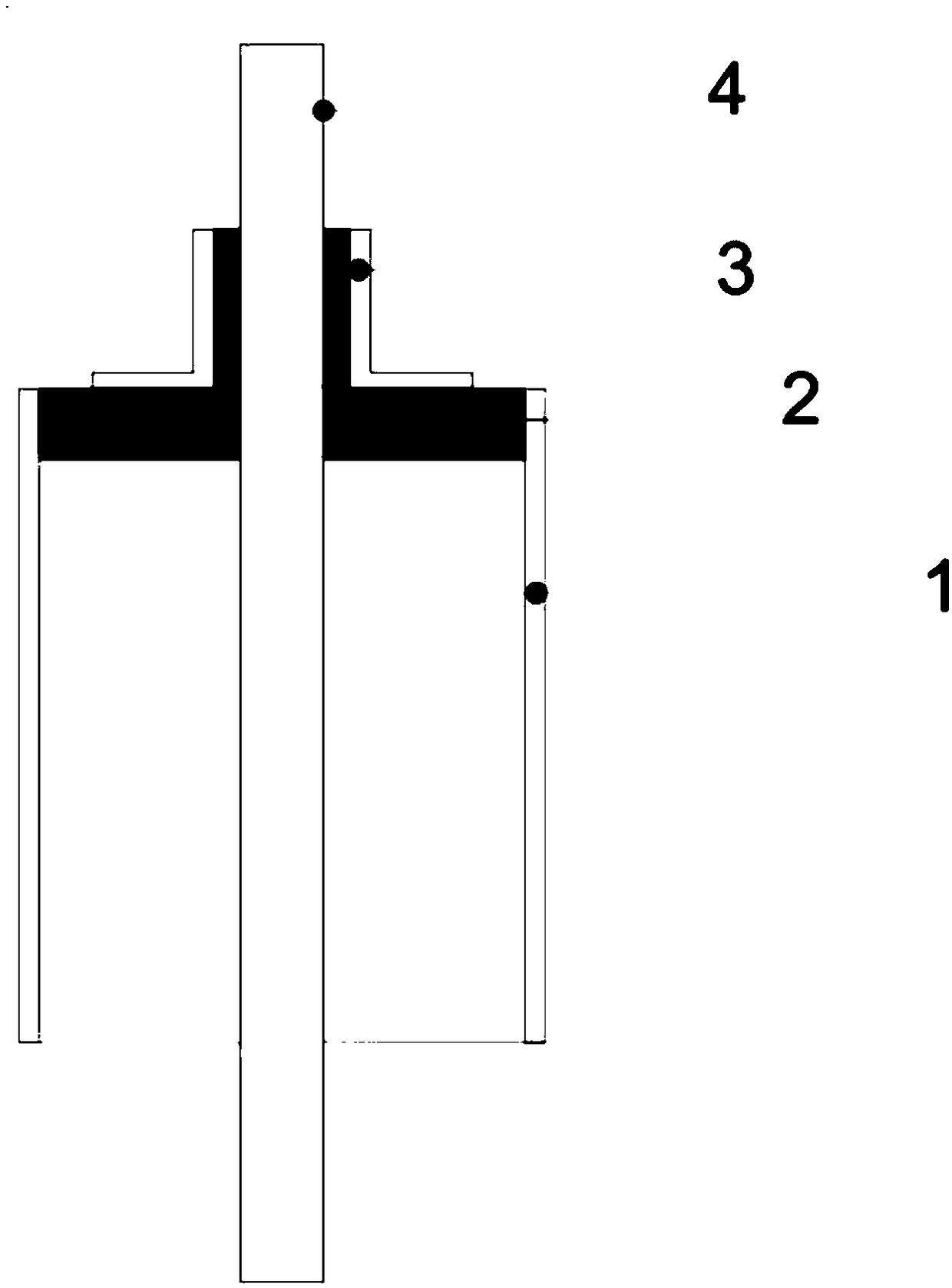

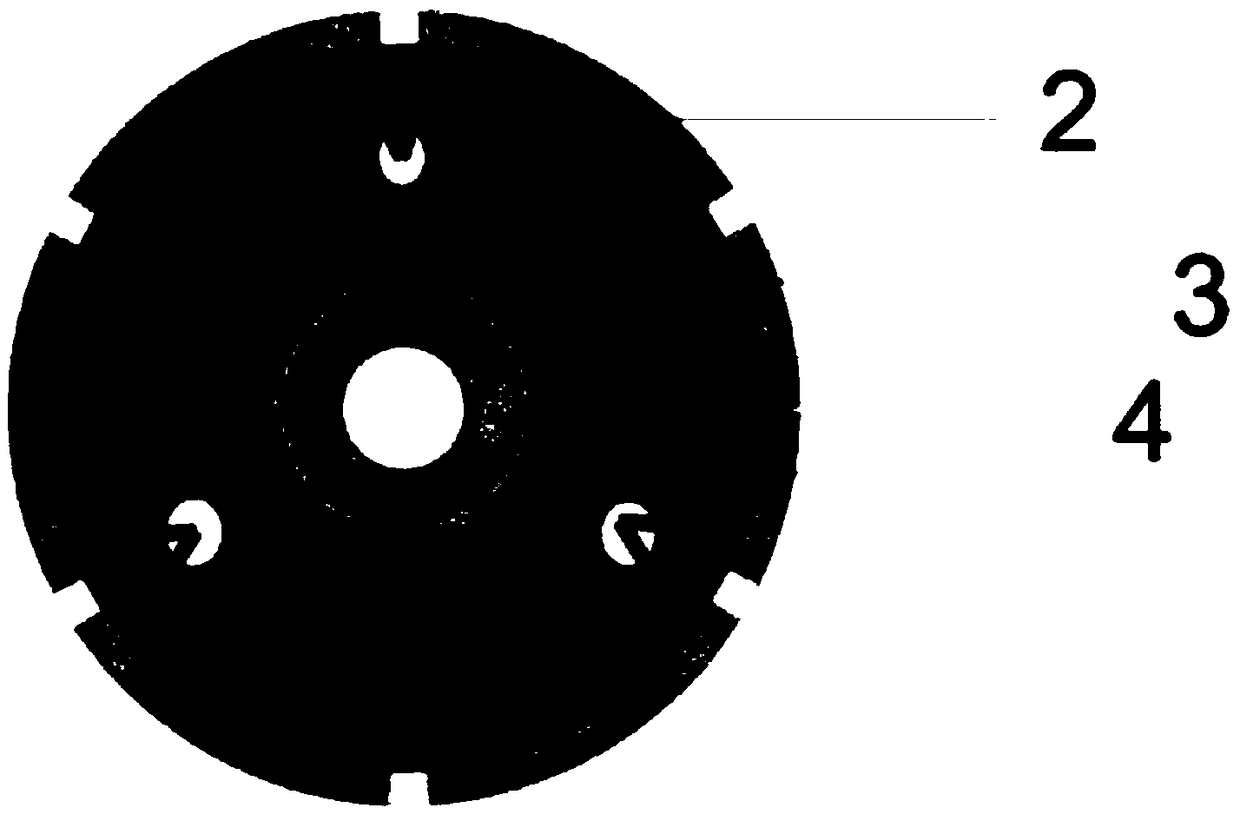

The invention discloses a quadrupole permanent-magnet brush coreless motor rotor structure. The structure comprises a cylindrical coil, a disc, a commutator and a shaft; the shaft is fixedly connectedwith the center of the disc, one end of the cylindrical coil is fixed to the circumference of the disc, and the disc is made of an insulating material; and the commutator is coaxially arranged on theouter side of the disc, the cylindrical coil comprises three coil groups, and each coil group at least comprises two independent coils and is provided with a wire inlet head and a wire outlet head which can be connected with the commutator. According to the structure, a magnetic circuit is shortened, flux leakage is prevented, the equipment weight is decreased, the motor heat loss is reduced, theefficiency is improved, the brush number is decreased, the structure is simple, the winding wire head arrangement is regular, and the process is simple.

Description

technical field [0001] The invention belongs to the technical field of motors, in particular to a rotor structure of a four-pole permanent magnet brushed hollow cup motor. Background technique [0002] Most of the current permanent magnet brushed coreless motors have a two-pole structure (that is, a pair of magnetic steel), and it is clear that the power density of a four-pole (that is, two pairs of magnetic steel) or more poles is higher than that of a two-pole motor; at the same time , affected by the structure of the brushed hollow cup motor, the magnetic circuit of the two-pole motor is long, resulting in a more prominent phenomenon of magnetic flux leakage outside the casing. The existing solution is to use a thicker casing to prevent magnetic flux leakage, so the weight of the motor increases. Lightweight is contradictory; under some specific requirements, the permanent magnet brushed hollow cup also adopts a four-pole structure, but in the form of four brushes, which ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K13/04H02K3/28

CPCH02K3/28H02K13/04H02K2213/03

Inventor 葛建勇

Owner 重庆长基科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com