In Situ Treatment Apparatus applying Pneumatic Fracturing and Forced Extraction for oil contaminated Soil

A soil purification and polluted soil technology, applied in the restoration of polluted soil, chemical instruments and methods, separation methods, etc., to achieve the effect of saving processing costs, shortening processing time, efficient and stable removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, specific contents of the present invention will be described in detail with reference to the accompanying drawings.

[0048] The present invention is not limited to the contents shown in the drawings, but can be configured in other forms, and this embodiment merely embodies the disclosed contents of the present invention.

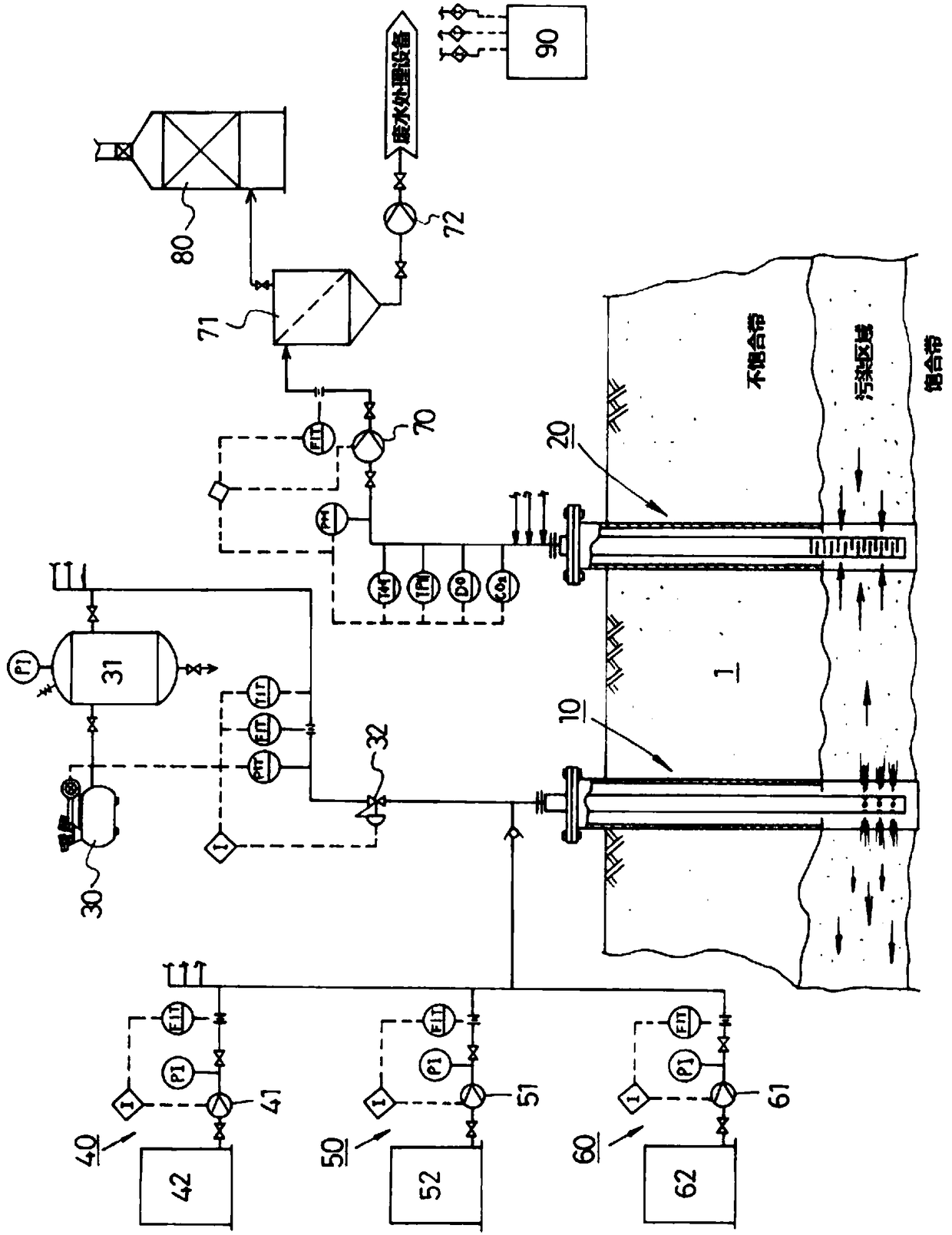

[0049] figure 1 It is an overall structural diagram of the in-situ underground treatment according to the present invention.

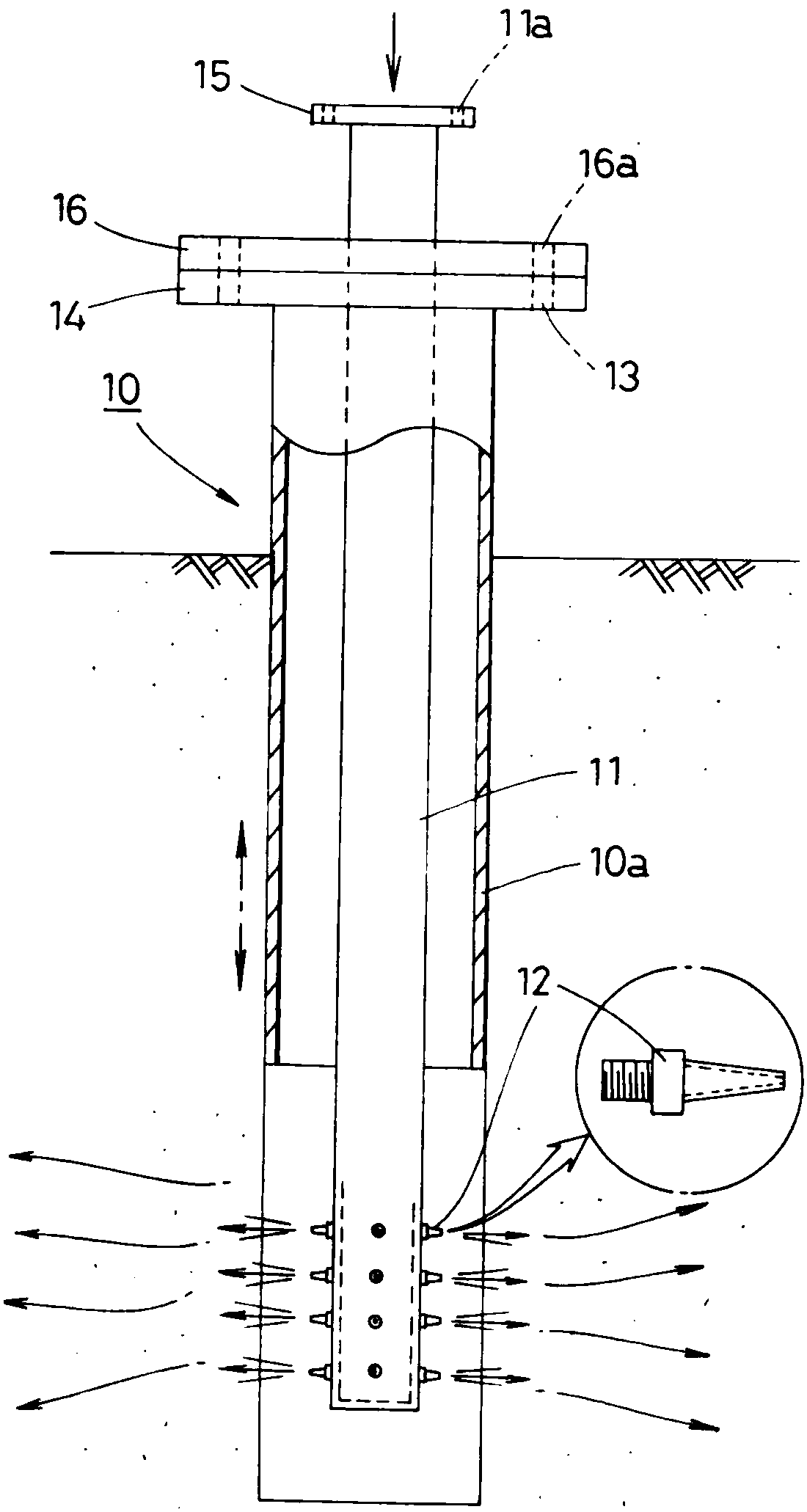

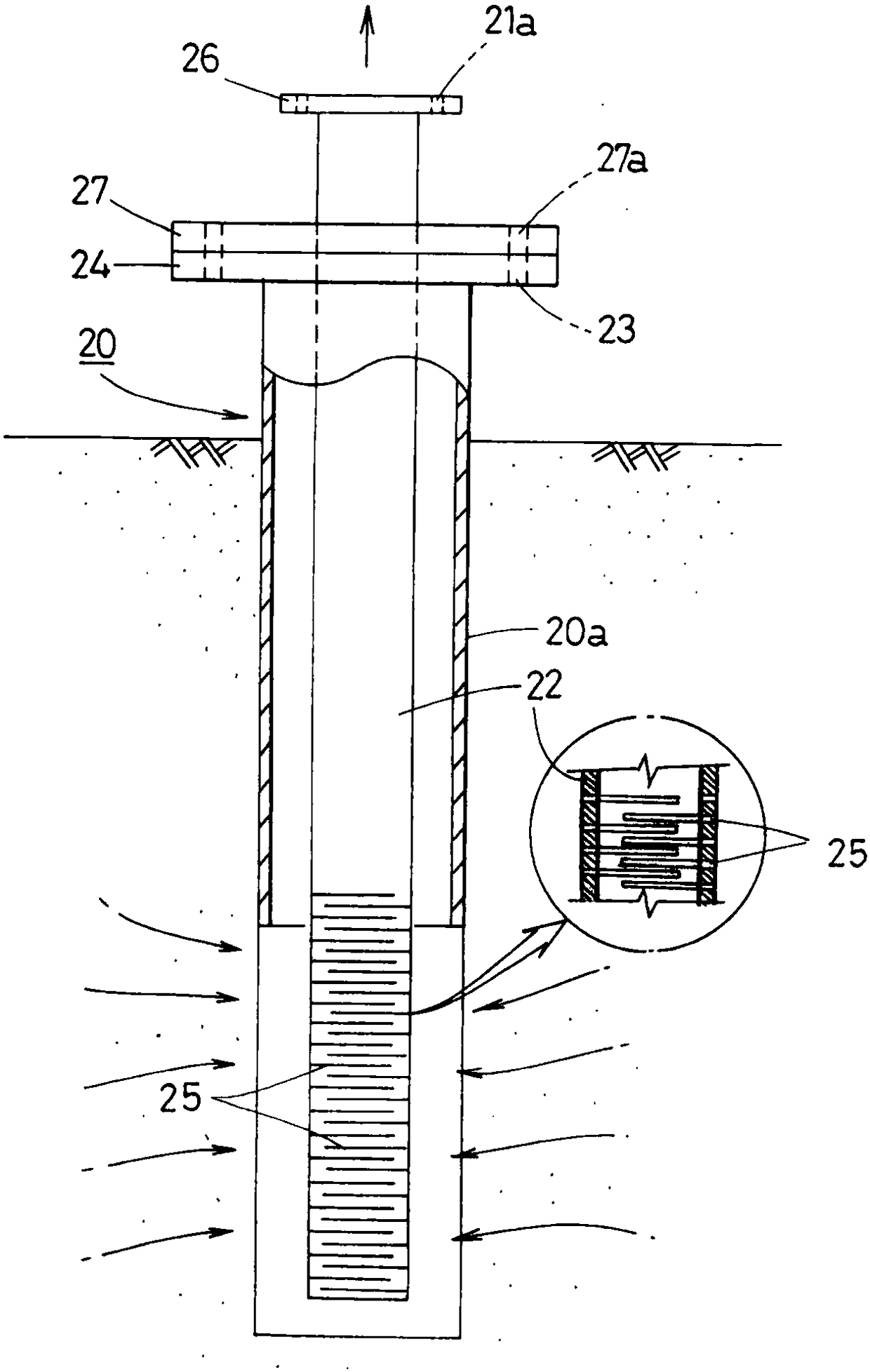

[0050] The present invention is composed of: an injection well 10, the injection well 10 is set to be buried in the polluted soil, so that the treatment medium can be smoothly injected and the treatment medium is in contact with the polluted soil; an extraction well 20, the extraction well 20 is set as Polluted substances can be discharged from the polluted soil to the outside; the air injector 30, which can deal with various components of soil such as mud and clay, plays a role in energy supply for air fragment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com