A bionic manipulator

A technology of manipulators and controllers, applied in the field of bionic manipulators, can solve problems such as weak grasping ability, unstable grasping force, and weak heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The following is a further detailed description of the embodiments of the present invention, and the purpose is to help the concepts and technical solutions of the present invention will be more complete, accurate and in-depth understanding of the concepts and technical solutions of the present invention. It helps to do it.

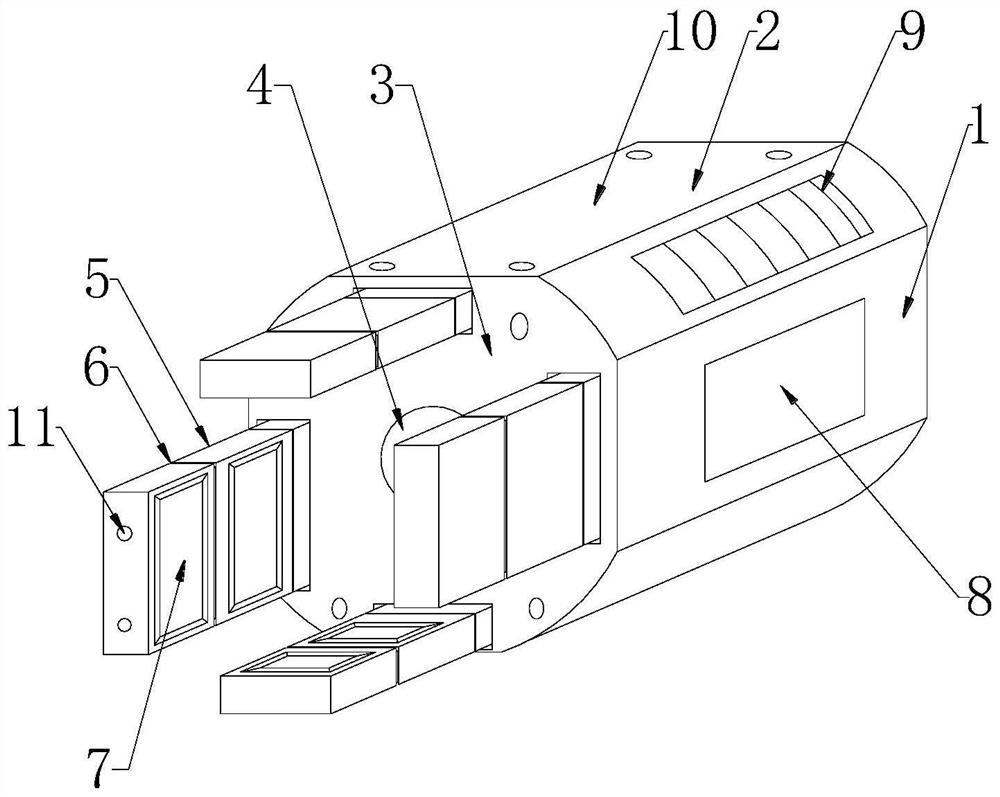

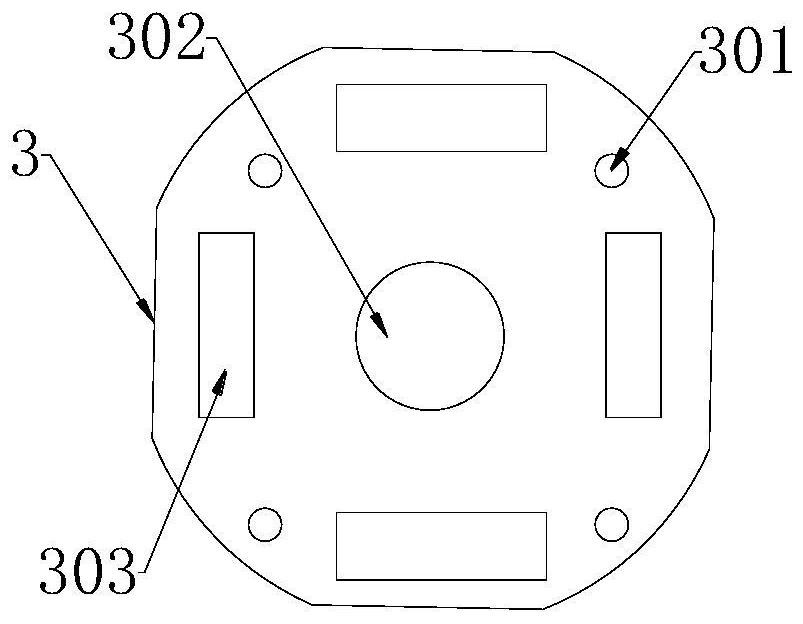

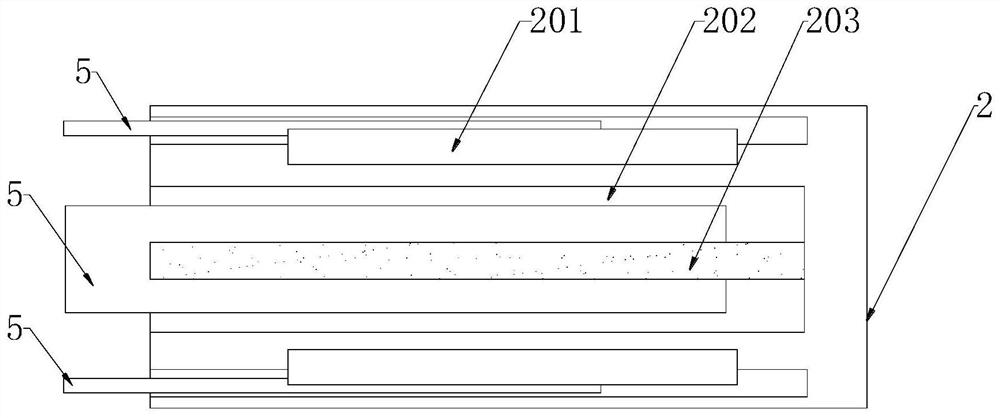

[0021]Specifically, ifFigure 1 to 4As shown, including the apparatus main body 1, the controller 2, and the grab finger 5, the controller 2 is provided, the controller 2 is electrically connected to the device body 1, and the front cover 3 is provided in front of the controller 2. The front cover 3 is connected to the controller 2, and the top end of the front cover 3 is provided with four threaded holes 301, and the threaded holes 301 are connected through the front cover 3, and the left side of the threaded holes 301 is provided with a movable hole 303, the movable hole 303 and the front The cover 3 runs through the connection, the intermediate portion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com