Pressing-pushing installation method of fabricated concrete prefabricated automobile box-type channel

An installation method and concrete technology, which can be applied in protection devices, water conservancy projects, artificial islands, etc., can solve problems such as staggering, disconnection, and loose connection of box sections, so as to improve the overall bearing capacity, solve the problem of water accumulation, The effect of tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

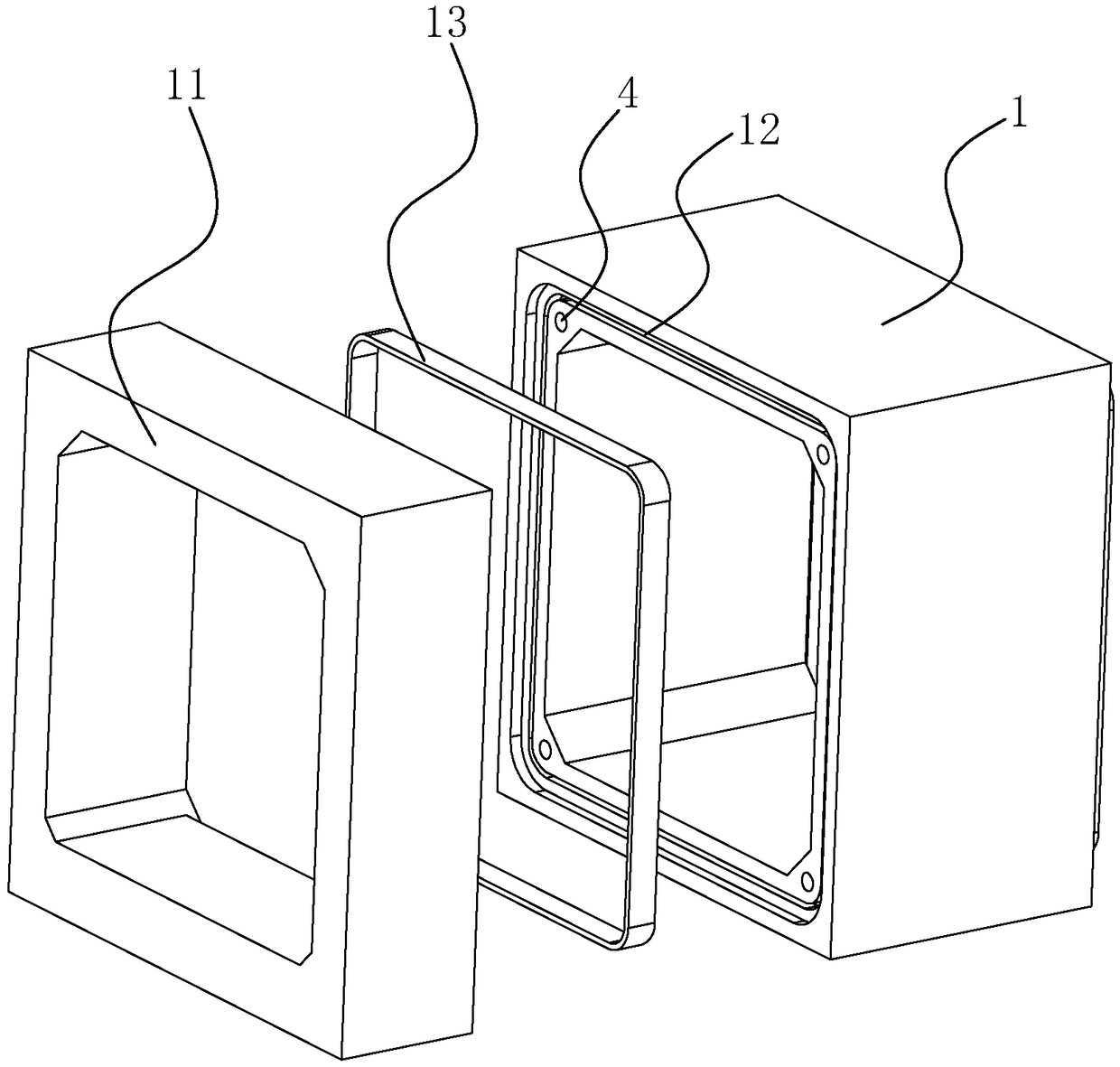

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0051] A method for pushing and installing a prefabricated prefabricated concrete car box, comprising steps:

[0052] S1. Clean up the debris on the surface and perform preliminary leveling, and then determine the outer control line of the excavation surface and the central axis of the passage according to the excavation depth and excavation slope.

[0053] S2. The channel base adopts one-way cement-soil mixing piles for soft foundation treatment. After the construction of one-way cement-soil mixing piles is completed and passed the inspection, the foundation pit can be excavated.

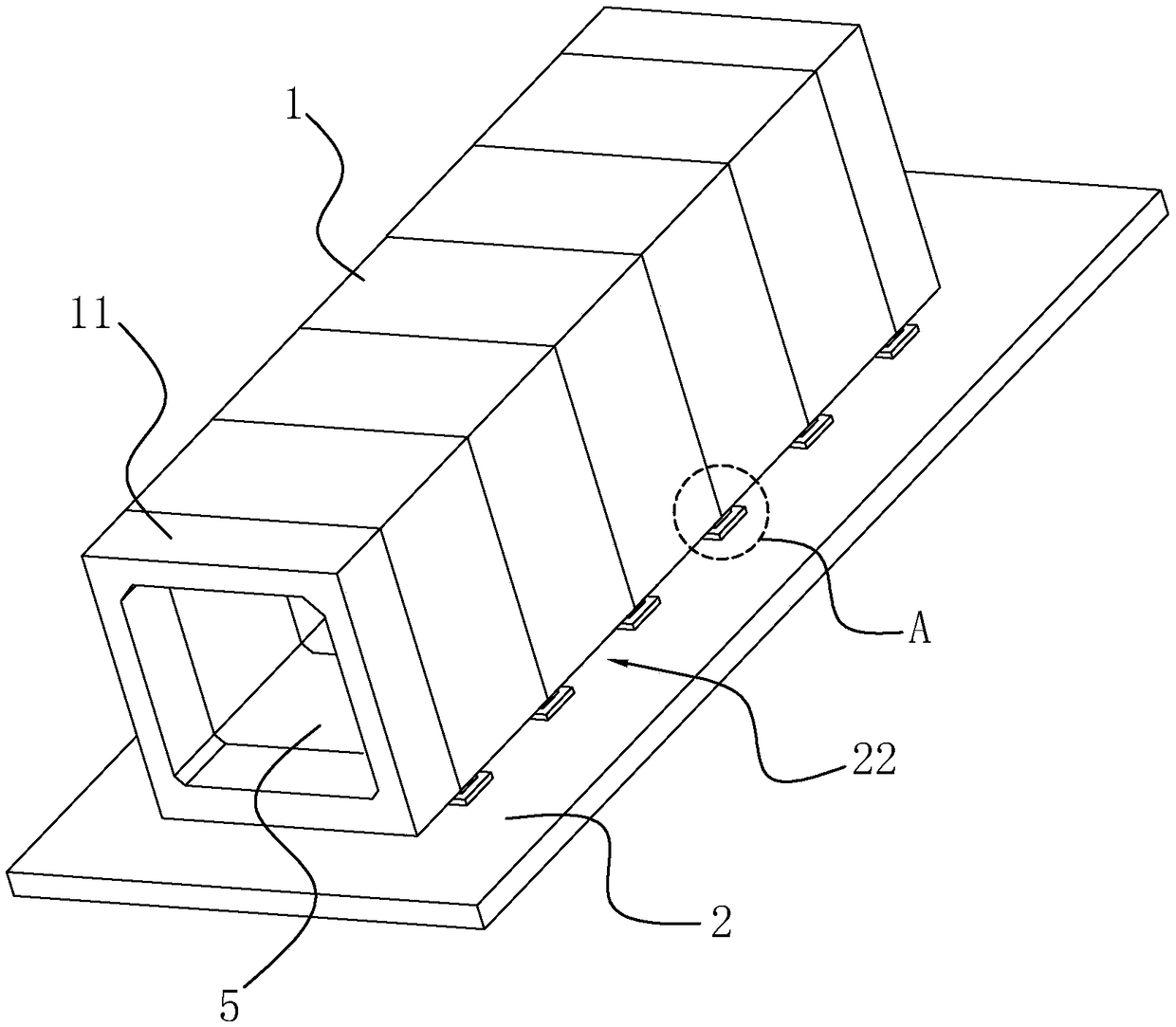

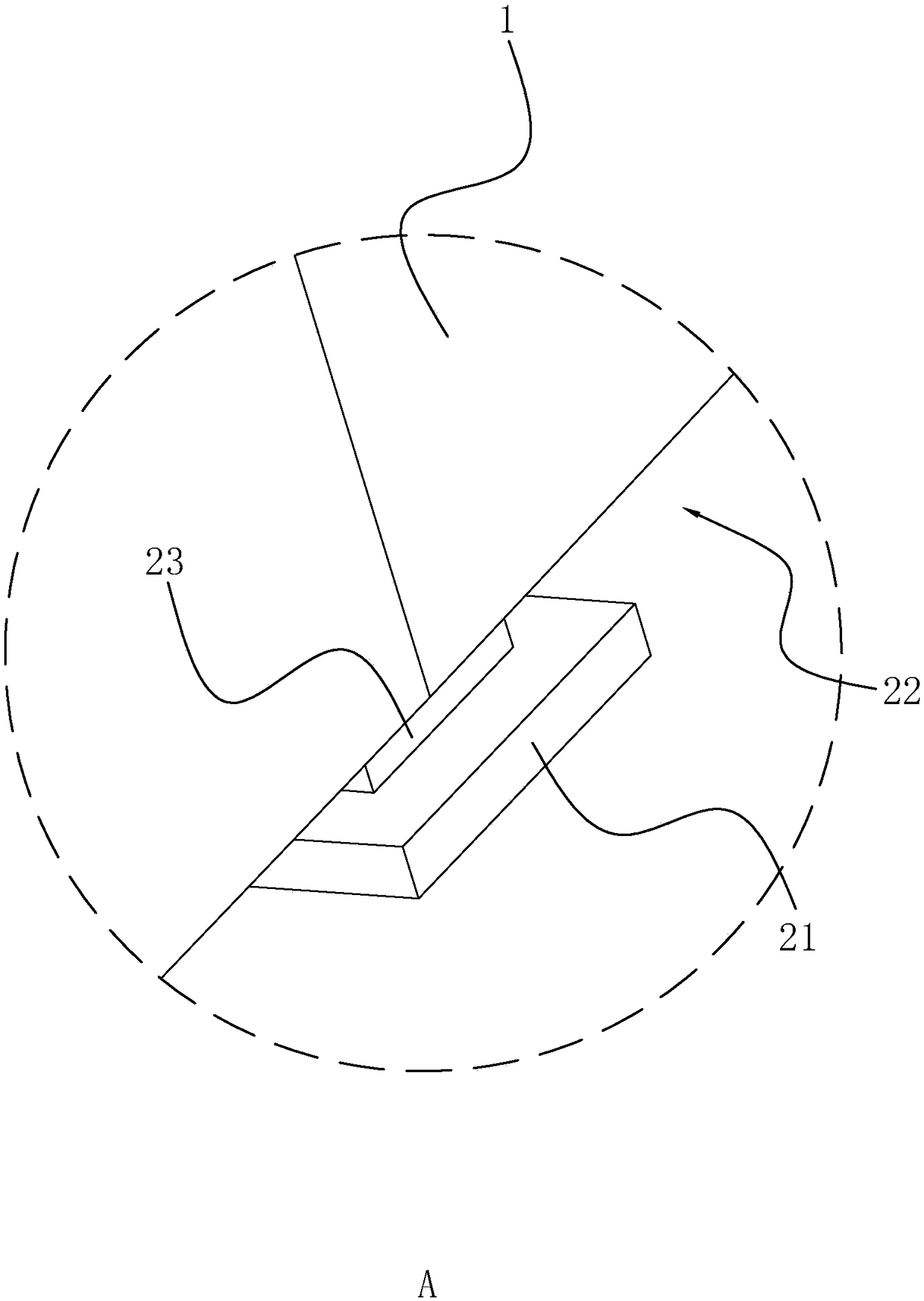

[0054] S3, refer to figure 1 , first lay the foundation cushion 2 composed of 30cm gravel and 20cm concrete, and no grading treatment is required during construction, so that the flatness of the surface is controlled within the range of 5mm, so as to ensure that the joints of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com