Control panel assembly of washing machine and washing machine

A control panel, washing machine technology, applied in other washing machines, washing devices, textiles and papermaking, etc., can solve problems such as affecting user experience, poor product refinement, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

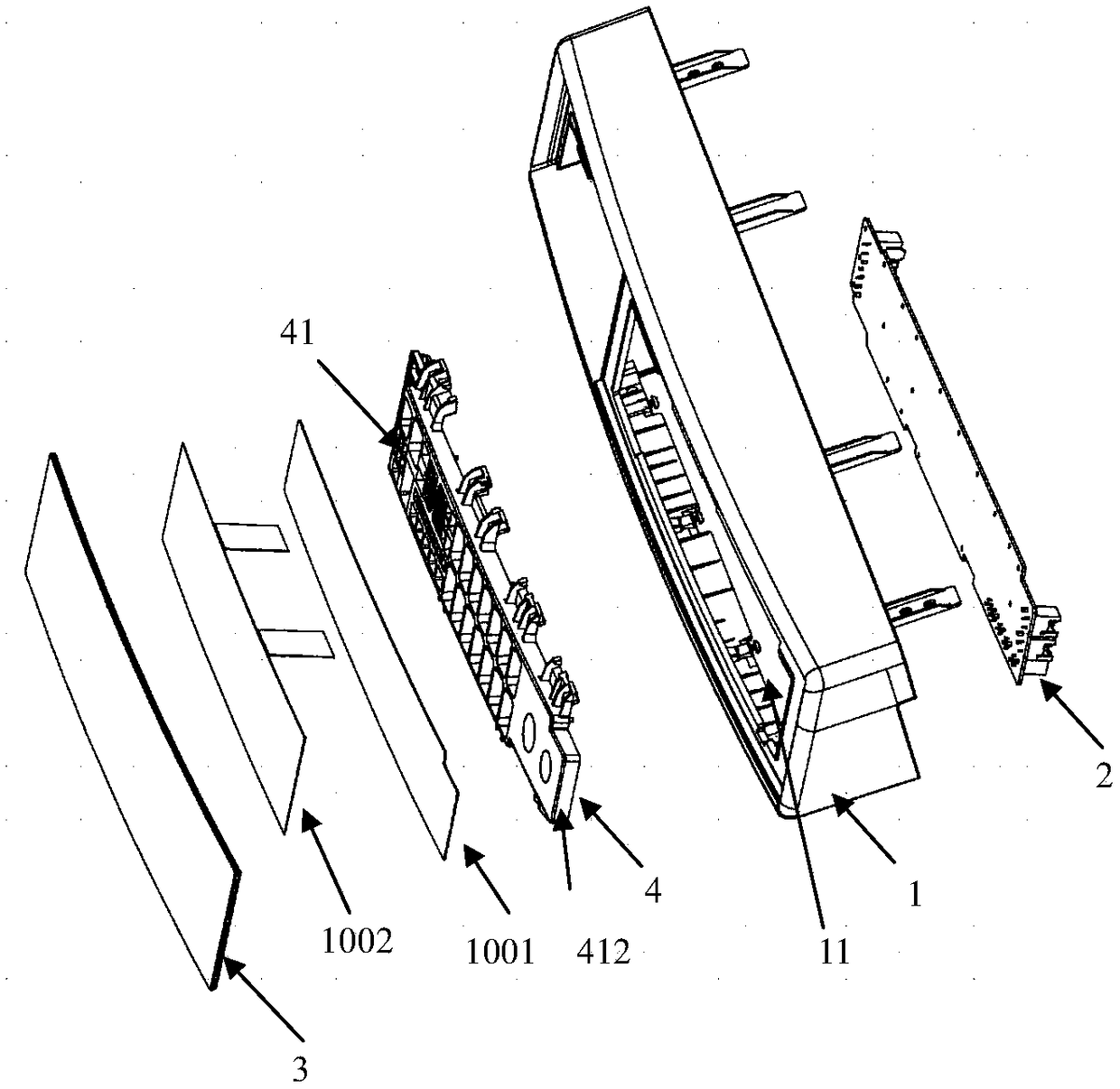

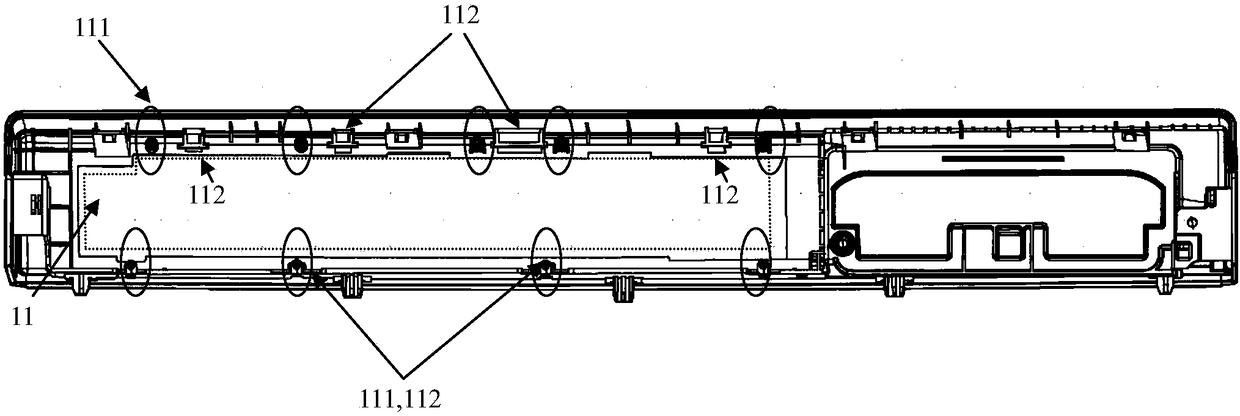

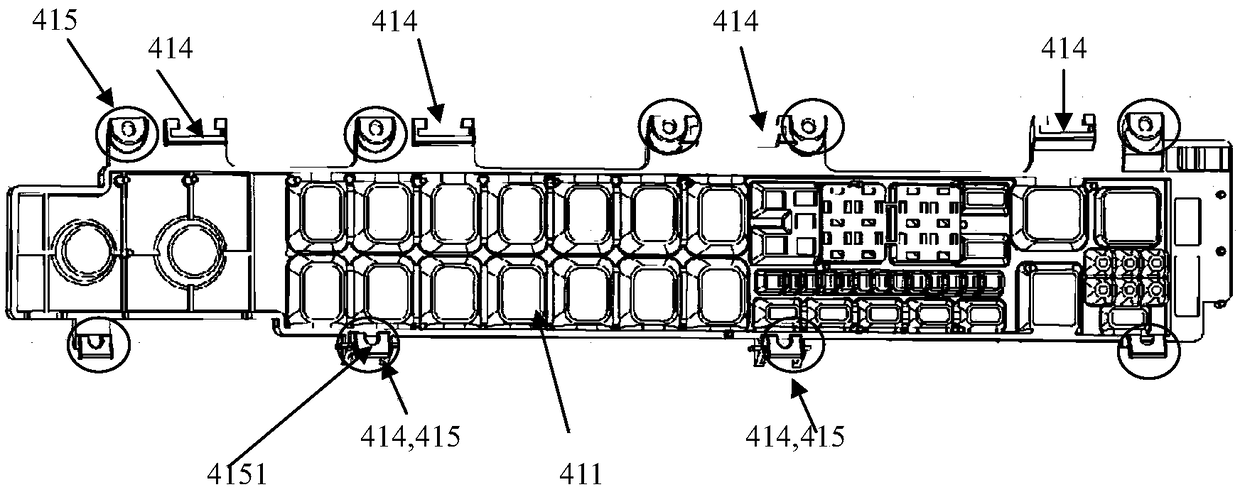

[0053] see Figure 1-Figure 6 As shown, this embodiment provides a washing machine control panel assembly, including a housing 1, a light emitting device 2, a decorative plate 3 and a lamp frame 4 with a light hole 411. After the light emitting device 2 is lit, the light passes through the lamp frame 4 The lamp hole 411 is projected onto the decorative panel 3, the housing 1 is provided with an installation opening 11, the lamp holder 4 is supported and installed in the installation opening 11, and is connected with the housing 1 Fasten the connection.

[0054] In the above solution, opening the installation opening 11 on the housing 1 affects the structural strength of the control panel assembly, resulting in a serious shortage of control panel strength, which is not conducive to later transportation. Therefore, the lamp holder 4 is installed in the installation opening 11. Therefore, the strength of the main control board is strengthened and improved.

[0055] Further, in ...

Embodiment 2

[0076] see Figure 7-Figure 14As shown, the second embodiment further describes the assembly drawing of the control panel assembly and the washing machine cabinet in detail on the basis of the first embodiment. A mounting hole 511 is provided on the board 51, and a plurality of insertion parts 12 protrude from one end of the control panel assembly. fit in the mounting hole 511 described above.

[0077] In the above solution, the insertion parts 12 are interference-connected to the installation holes 511 on the installation plate 51, then when the control panel assembly is installed, each insertion part 12 at one end of the control panel assembly is inserted into the washing machine cabinet 5 respectively. In the mounting hole 511, the other end of the control panel assembly is rotated toward the washing machine to be assembled on the washing machine. The mounting hole 511 cuts the insertion part 12 to form a slot 1221, thereby more effectively restricting the control panel as...

Embodiment 3

[0106] Embodiment 3 provides a washing machine using the control panel assembly in Embodiment 1 or Embodiment 2 above.

[0107] For the washing machine control panel assembly of this embodiment, see Figure 7 As shown, there are positioning rib a6, positioning rib b61, positioning surface a62, positioning surface b63, positioning surface c64, positioning surface d65, socket part 12, positioning claw 66 (for clamping on the box body 5) on it. beam 9) etc. Figure 9-Figure 12 It is the structure of the washing machine box 5, including but not limited to the rear shell 10 (or two side plates and the rear plate) and the front plate 7, wherein, the rear shell 10 has a positioning hole a152, a positioning hole b153, and a positioning surface a154 , Positioning surface b155, positioning surface c156, positioning surface d157. During the installation process, first insert the socket part 12 on the control panel assembly into the installation hole 511 on the front panel 7, and then f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com