Preparation method of nanoparticle line array resistor

A nanoparticle and line array technology, applied in the direction of resistance manufacturing, resistors, circuits, etc., can solve problems such as expensive equipment, cumbersome operation, and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

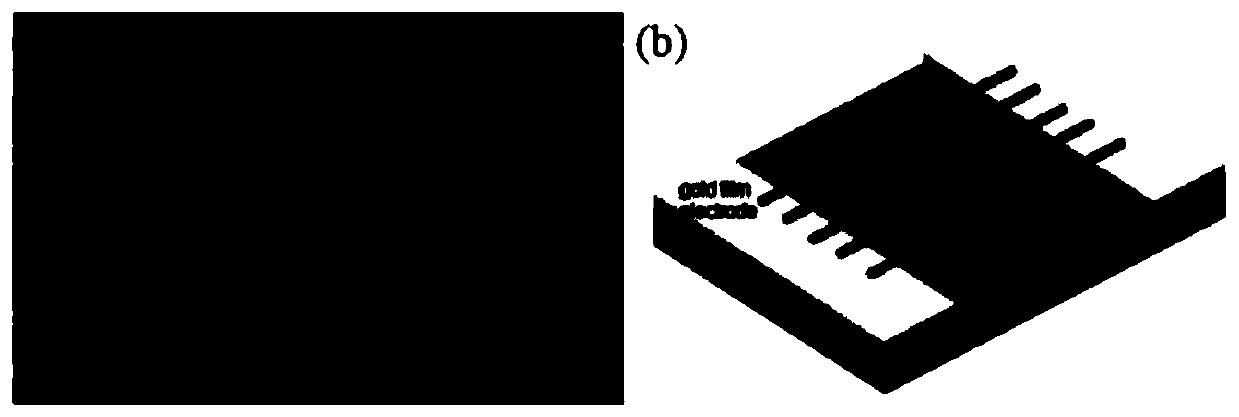

[0024] The invention provides a method for preparing nanoparticle line array resistors, specifically as figure 1 As shown, it includes a femtosecond laser system, a three-dimensional micro-displacement platform, an optical path system, and a PC. The optical path system includes a half-wave plate, a Glan prism, a diaphragm, a shutter, and a focusing objective lens. The prepared sample is placed on the three-dimensional micro-displacement platform through the half-wave plate, Glan prism, diaphragm, shutter and focusing objective lens placed at intervals. The femtosecond pulse laser is focused on the prepared sample through the focusing objective lens, and the three-dimensional micro-displacement platform and the shutter pass through PC control; figure 1 The XYZ platform in is the above-mentioned three-dimensional micro-displacement platform.

[0025] Concrete preparation method comprises the following steps:

[0026] Step 1. Coating a gold film on the glass surface, and then c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com