Mechanical positioning printing and dyeing pattern making cup cover opening device

A technology of mechanical positioning and cap opening device, which is applied in the direction of processing textile material dyeing devices, etc., can solve the problems of low cap opening efficiency, bumps, complicated precise positioning structure, etc., and achieve the effect of convenient automatic cap opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

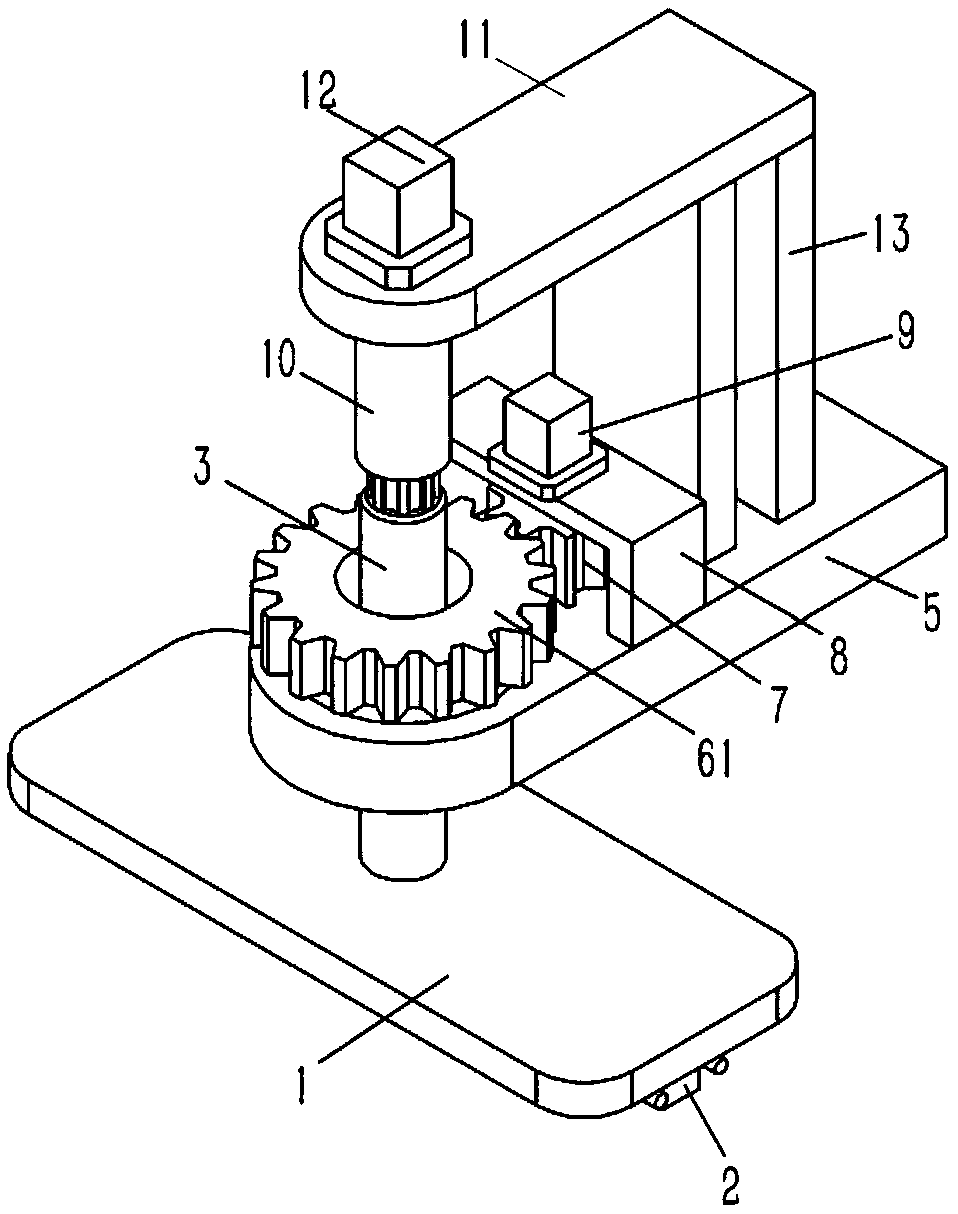

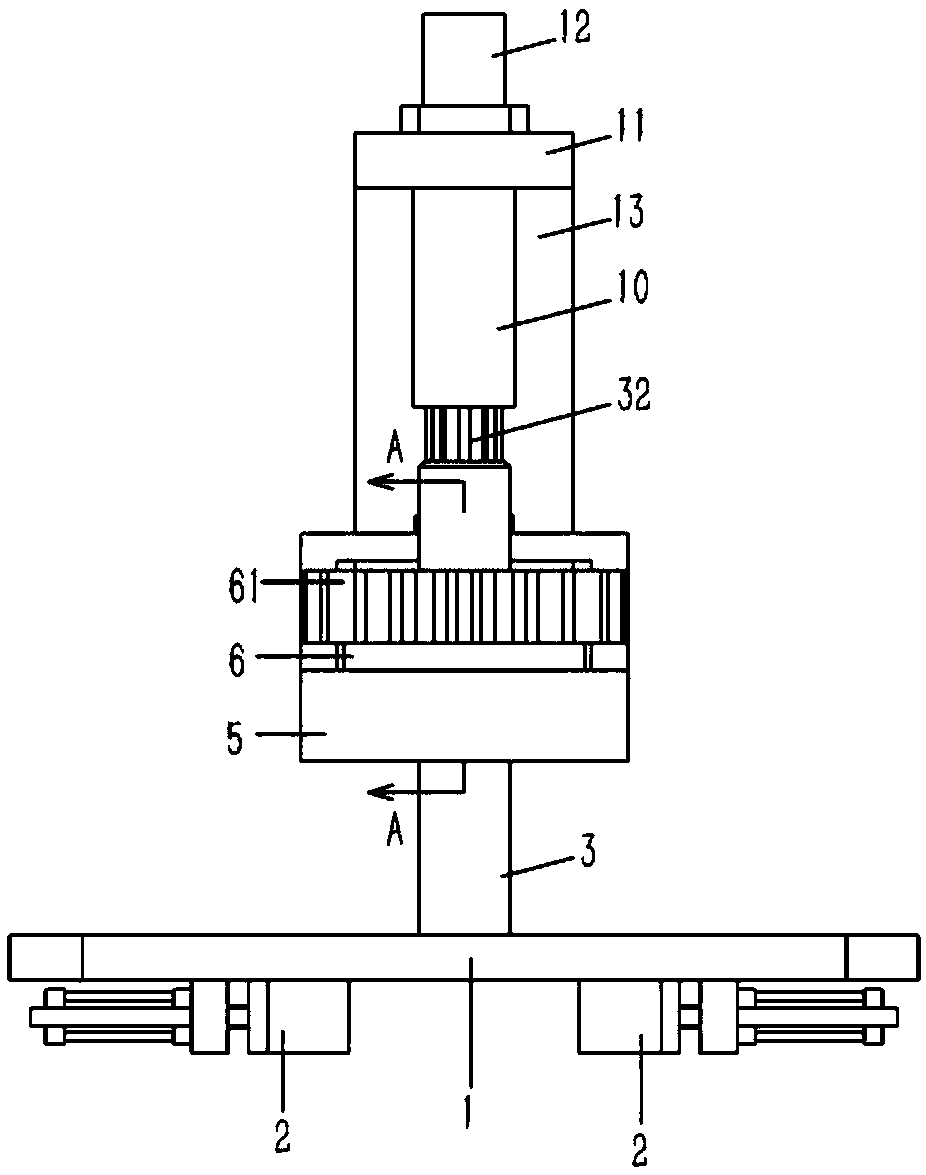

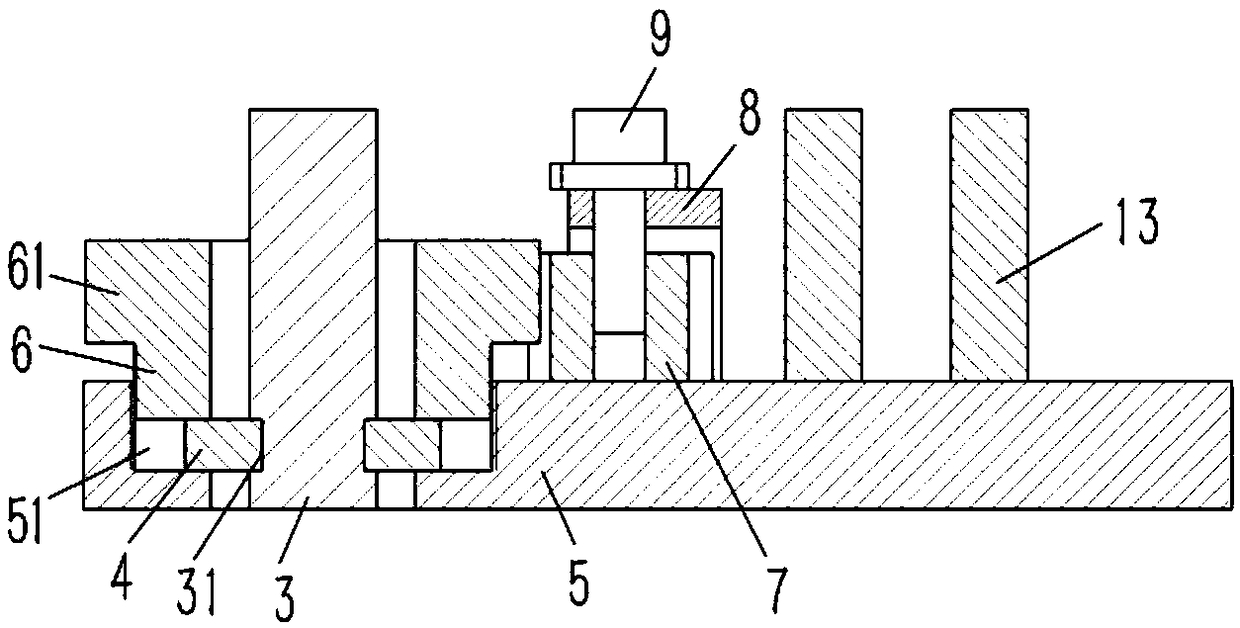

[0019] Example: see Figures 1 to 4 As shown, a mechanically positioned printing and dyeing cup opening device includes a rectangular bottom plate 1 and a fixing plate 5 distributed on the upper side of the bottom plate 1, and a clamping mechanism 2 is fixed on both sides of the lower end surface of the bottom plate 1 to clamp The mechanism 2 includes a fixed block 22 fixed on the base plate 1. The side of the fixed block 22 close to the center of the base plate 1 is provided with a V-shaped clamp block 21. The two sides of the rear end surface of the V-shaped clamp block 21 are fixed with guide posts 23. The guide posts 23 Inserted on the fixed block 22, the fixed block 22 between the guide columns 23 is fixed with a clamping cylinder 24, and the piston rod of the clamped cylinder 24 passes through the fixed block 22 and is fixed on the V-shaped clamping block 21;

[0020] A vertical rotating main shaft 3 is fixed on the upper end surface of the center of the base plate 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com