Fermentation tank

A fermenter and strain tank technology, applied in the fermenter field, can solve problems such as long time-consuming, inability to guarantee the quality of production materials, and cumbersome preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the examples.

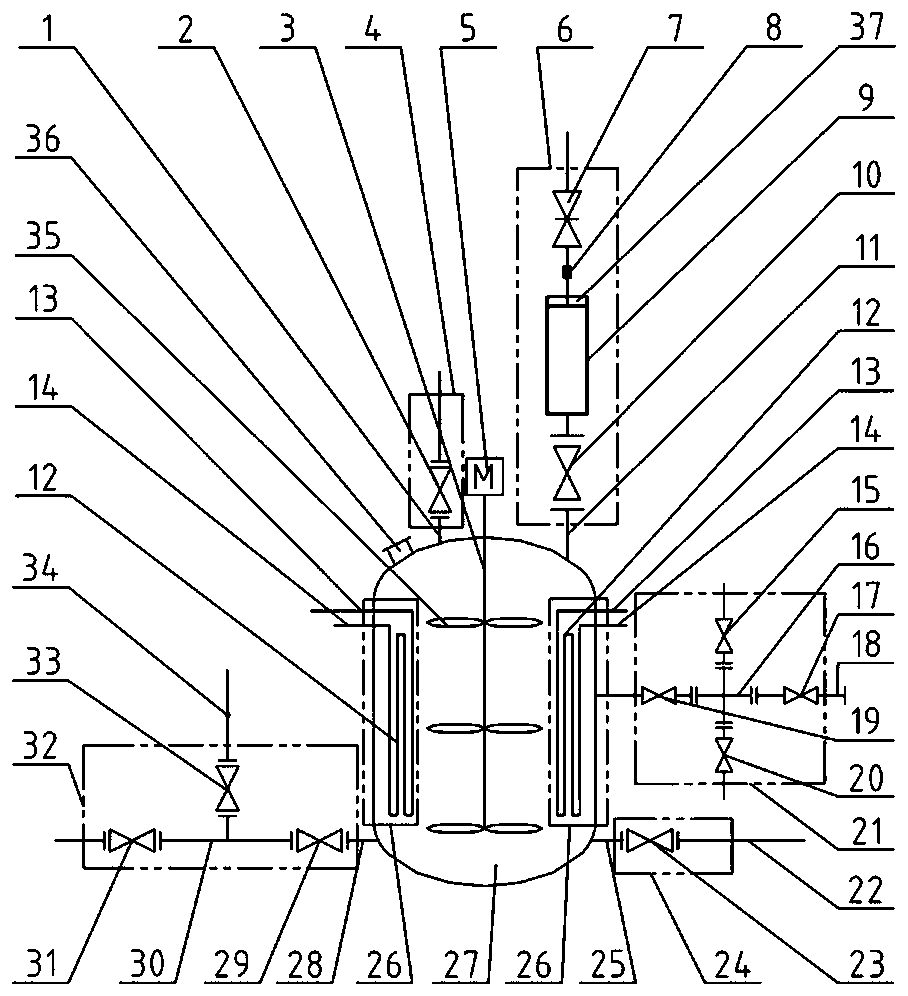

[0016] Such as figure 1 Shown, be a kind of embodiment of the present invention, be provided with fermentation tank body 27, be provided with stirring motor 5 in the middle position above fermentation tank body 27, stirring motor 5 is connected with the stirring shaft 3 of fermentation tank body 27 inner chambers, stirring shaft 3 is provided with an agitator 35, and the fermenter body 27 is also provided with a feeding port 36, the fermenter body 27 is provided with a strain feeding device 6, the fermenter body 27 is provided with an exhaust device 4, and the fermenter body 27 outside The middle part is provided with a sampling and bacteria separation device 21, a steam sterilization discharge device 32 is provided on one side of the lower end of the fermentation tank body 27, an oxygenation device 24 is provided on the other side of the lower end of the fermentation tank body 27,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com