Chassis and vehicle using chassis

A chassis and vehicle technology, applied in vehicle components, steering mechanisms, transportation and packaging, etc., can solve problems such as insufficient compensation force at small angles, and achieve the effect of ensuring return-to-alignment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

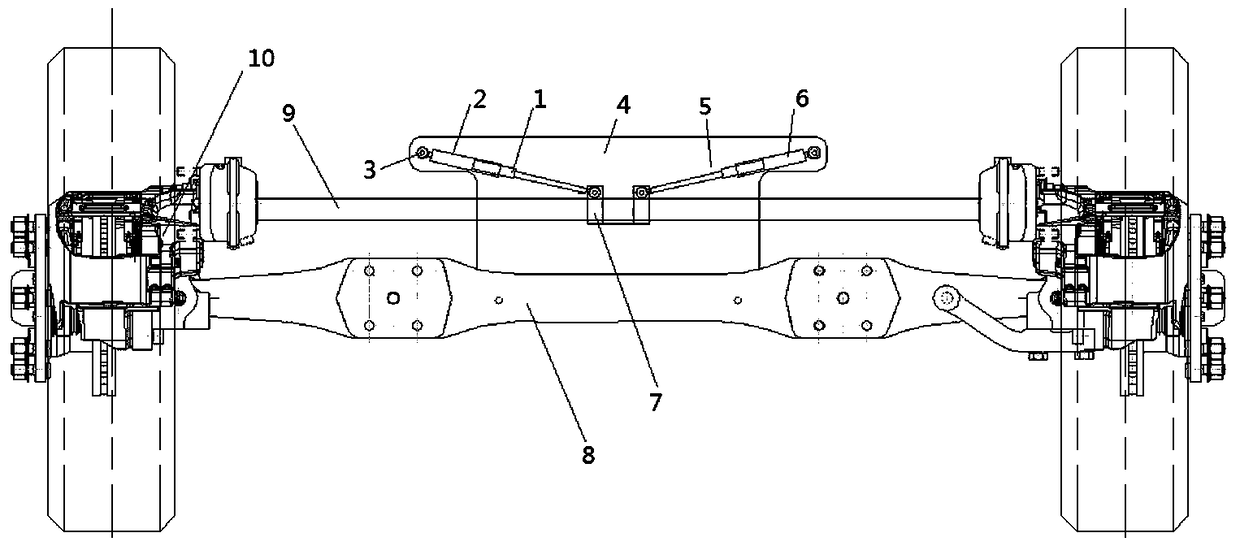

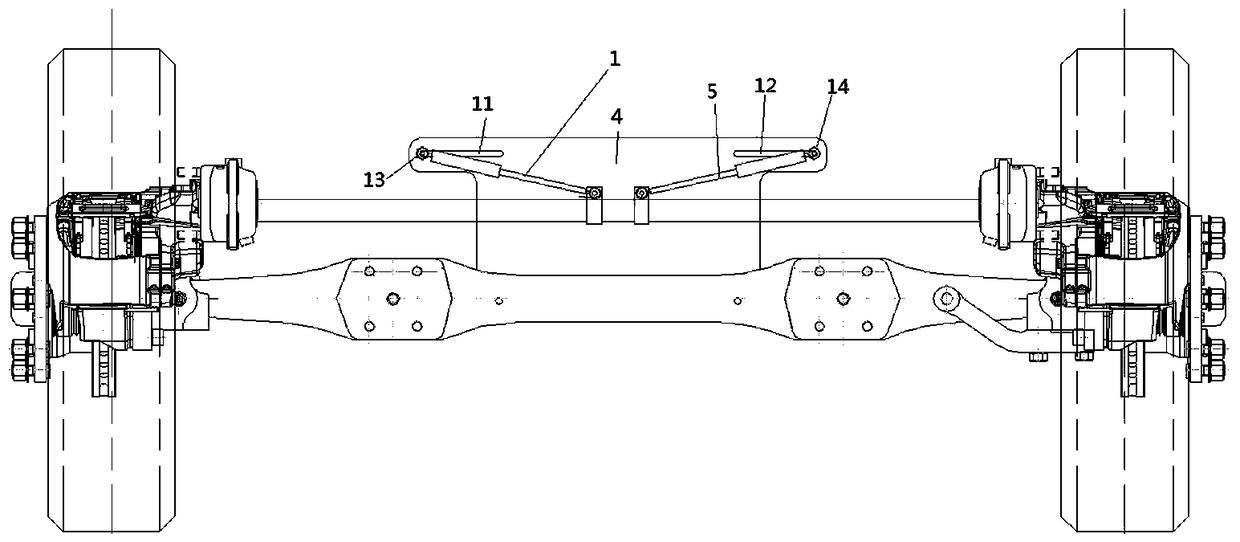

[0021] Example 1 of the vehicle as figure 1 Shown: It includes a chassis and a body (not shown in the figure) set on the chassis. The driving area of the body is provided with a steering wheel. The chassis includes an axle 8 and steering knuckles 10 at both ends of the axle. The steering wheel is connected to one of the steering knuckles for transmission. Connected, a steering pull rod 9 is arranged between the two steering knuckles. Between the axle 8 and the steering rod 9, there are a pair of first return compensating gas spring 1 and second return compensating gas spring 5, first return compensating gas spring 1, second return compensating gas spring 5 Arranged left and right, the vehicle axle is provided with a gas spring connecting plate 4 which is connected with each positive compensation gas spring, the gas spring connecting plate 4 is a horizontally arranged convex structure, and the narrow side of the gas spring connecting plate 4 is fixed on the axle by bolts 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com