Multifunctional rotary displacement conveying mechanical arm capable of taking materials in branched mode

A technology of rotating, shifting and conveying machinery, applied in the field of robotic arms, can solve the problems of not being able to meet the production needs of multiple varieties and small batches, low conveying efficiency, and increased equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

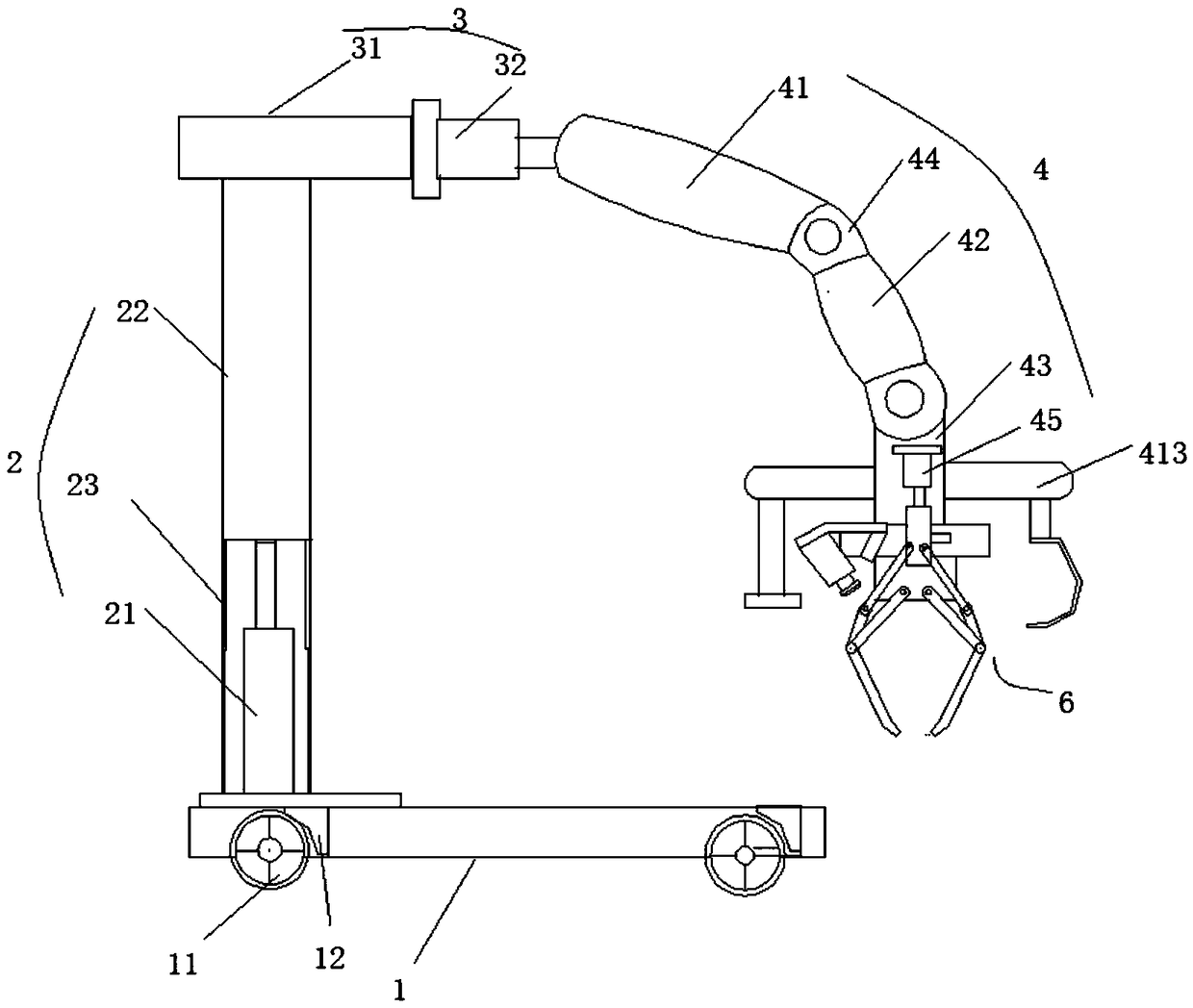

[0100] Such as figure 1 The shown a kind of conveying mechanical arm capable of branching and taking materials with multifunctional rotation and displacement includes a base 1, a lifting column 2, a traverse mechanism 3, a mechanical arm 4, a connecting piece 5 and a mechanical claw 6, and the lifting column 2 The rotating disk 7 is fixed on the base 1, and the traversing mechanism 3 is arranged on the lifting column 2. The lifting column 2 includes a lifting cylinder 21 and a supporting column 22. The bottom of the lifting cylinder 21 is arranged on the rotating disk 7. The moving mechanism 3 is a horizontal cylinder 31 and a beam 32, the beam 32 is connected with the piston rod of the lifting cylinder 21, the horizontal cylinder 31 is arranged on the beam 32, and the piston rod of the horizontal cylinder 31 is connected with the mechanical arm 4; The arm 4 is provided with a plurality of spherical annular holes 411, and a spherical fixed ring 412 is installed in the spherica...

Embodiment 2

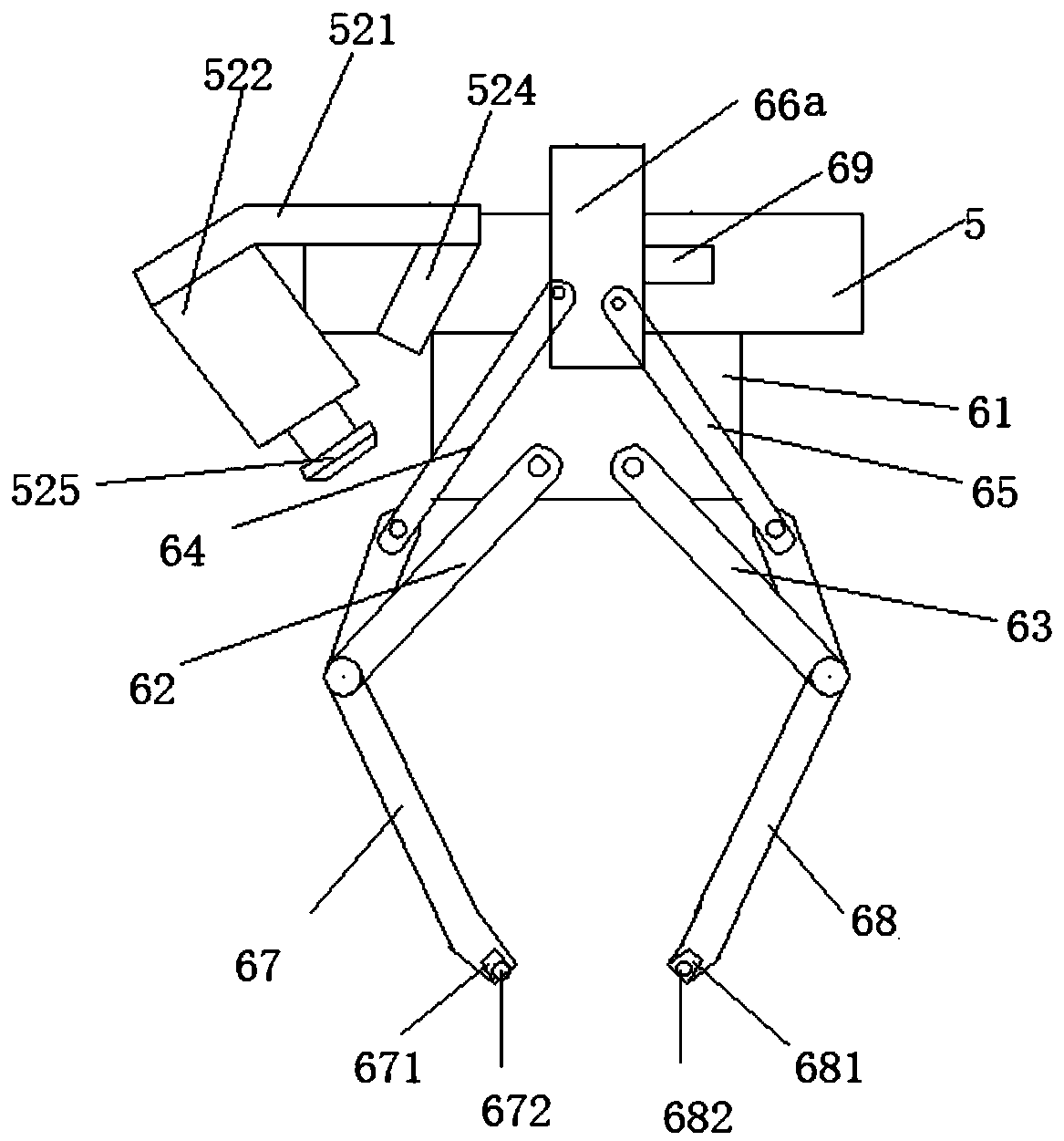

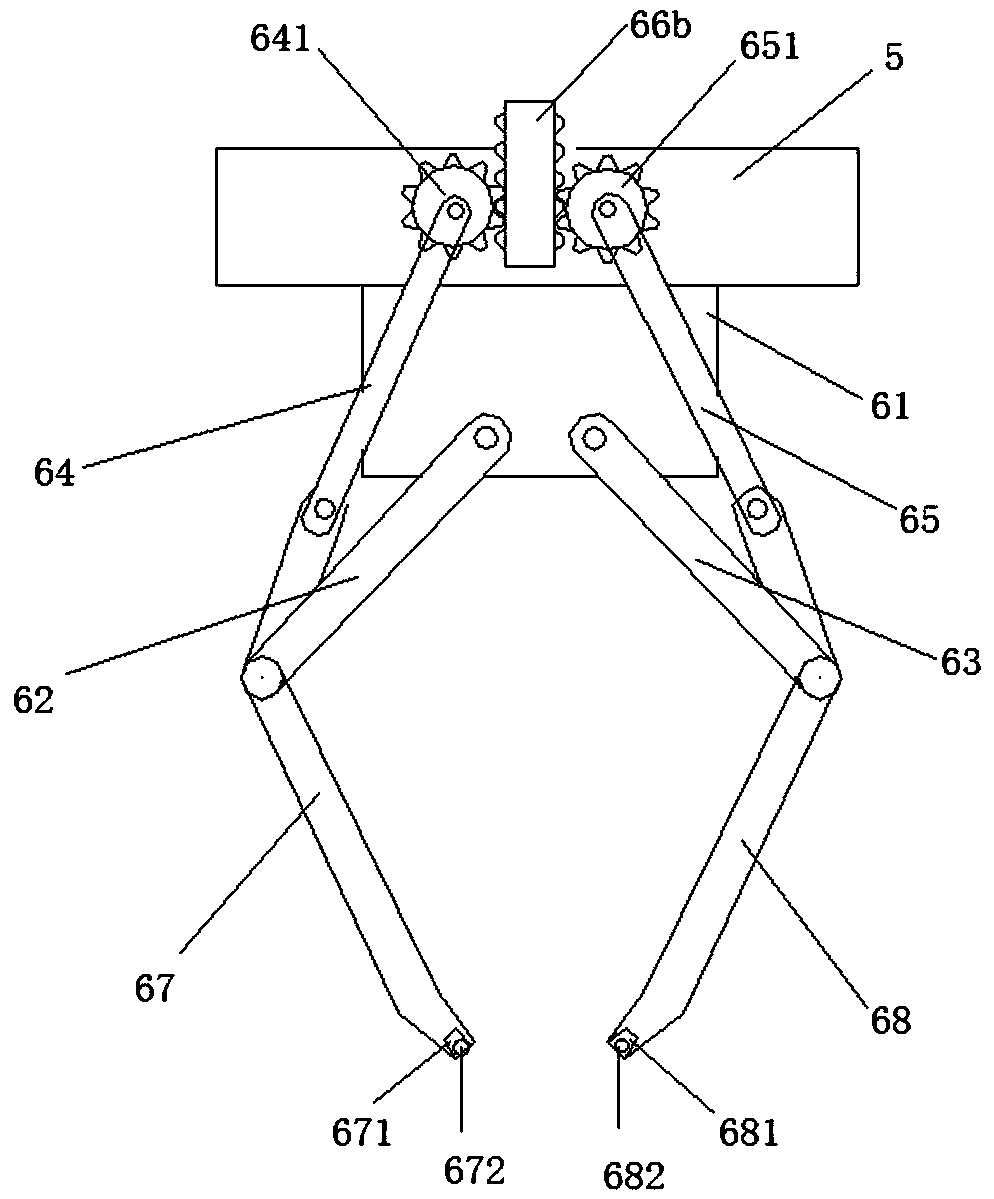

[0102] Such as figure 1 , 4 , 5, 6 and 7 shows a multi-functional rotating and shifting conveying robot arm capable of branching and retrieving materials, including a base 1, a lifting column 2, a lateral movement mechanism 3, a robot arm 4, a connecting piece 5 and a mechanical claw 6 , the lifting column 2 is fixed on the base 1 through the rotating disc 7, the traversing mechanism 3 is arranged on the lifting column 2, and the lifting column 2 includes a lifting cylinder 21 and a supporting column 22, and the bottom of the lifting cylinder 21 is arranged on a rotating On the disk 7, the traverse mechanism 3 is a transverse cylinder 31 and a beam 32, the beam 32 is connected with the piston rod of the lift cylinder 21, the transverse cylinder 31 is arranged on the beam 32, the piston rod of the transverse cylinder 31 is connected to the mechanical arm 4 connection; The mechanical arm 4 is provided with a plurality of spherical ring holes 411, a spherical fixing ring 412 is ...

Embodiment 3

[0112] Such as figure 1 , 4 , 5, 6 and 7 shows a multi-functional rotating and shifting conveying robot arm capable of branching and retrieving materials, including a base 1, a lifting column 2, a lateral movement mechanism 3, a robot arm 4, a connecting piece 5 and a mechanical claw 6 , the lifting column 2 is fixed on the base 1 through the rotating disc 7, the traversing mechanism 3 is arranged on the lifting column 2, and the lifting column 2 includes a lifting cylinder 21 and a supporting column 22, and the bottom of the lifting cylinder 21 is arranged on a rotating On the disk 7, the traverse mechanism 3 is a transverse cylinder 31 and a beam 32, the beam 32 is connected with the piston rod of the lift cylinder 21, the transverse cylinder 31 is arranged on the beam 32, the piston rod of the transverse cylinder 31 is connected to the mechanical arm 4 connection; The mechanical arm 4 is provided with a plurality of spherical ring holes 411, a spherical fixing ring 412 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com