Compensation method and device for dispensing height

A compensation method and a technology of a compensation device, which are applied in the direction of the device and coating of the surface coating liquid, can solve the problems of inaccurate dispensing position, influence of dispensing effect, poor effect, etc., and achieve stable dispensing effect and improved The effect of dispensing efficiency and improving dispensing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

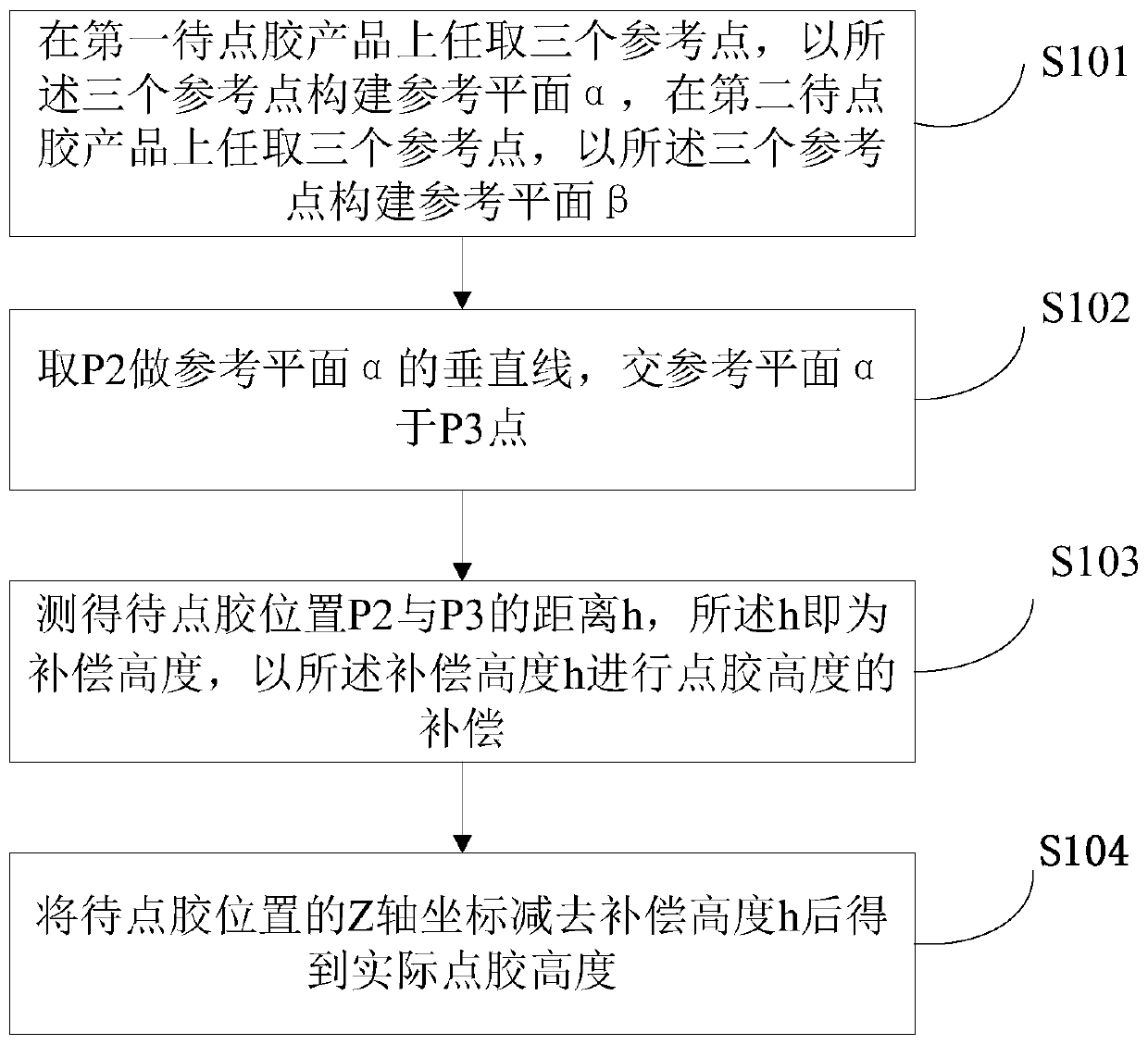

[0025] refer to figure 1 As shown, the compensation method of the dispensing height includes:

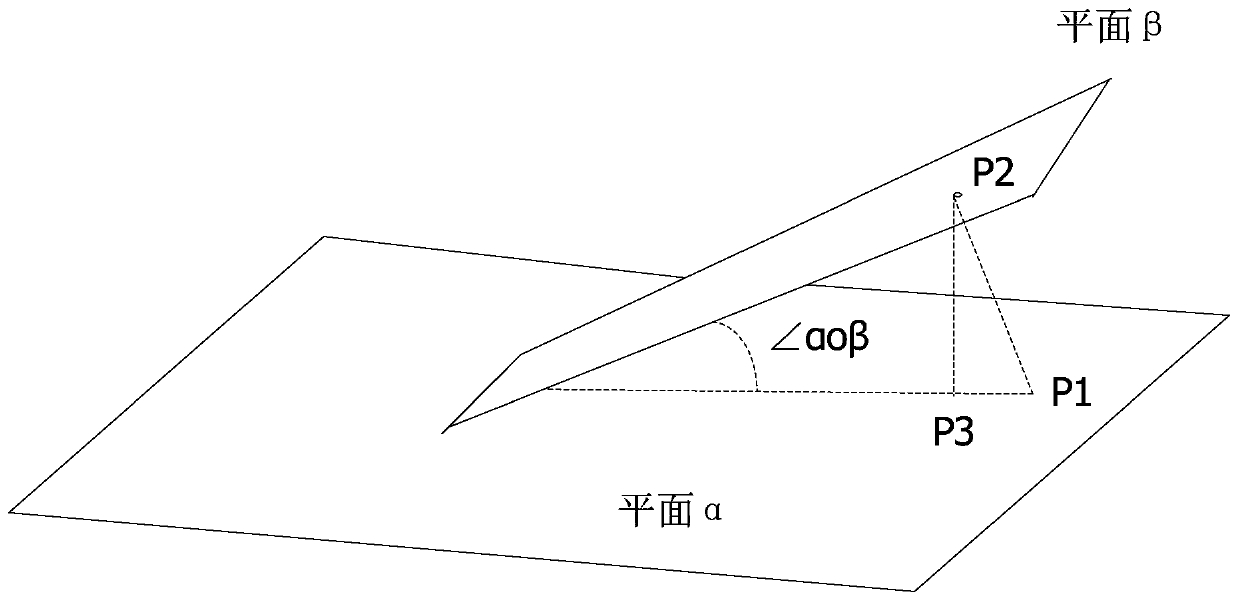

[0026] S101: randomly select three reference points on the first product to be dispensed, construct a reference plane α with the three reference points, and randomly select three reference points on the second product to be dispensed, and construct a reference plane α with the three reference points Reference plane β, wherein, there is a position P1 to be dispensed on the reference plane α, and a position P2 to be dispensed on the reference plane β, and the positions P1 and P2 to be dispensed are the same position on the product to be dispensed.

[0027] S102: Take P2 as the vertical line of the reference plane α, and intersect the reference plane α at point P3.

[0028] S103: Measure the distance h between the positions P2 and P3 to be dispensed, the h is the compensation height, and use the compensation height h to compensate the dispensing height of the second position P2 to be ...

Embodiment 2

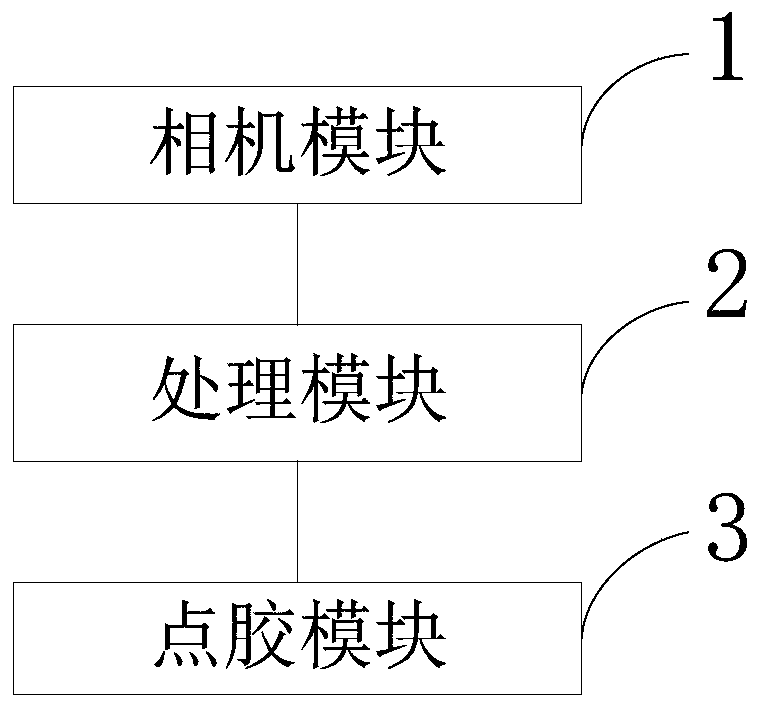

[0040] refer to image 3 As shown, it is a schematic structural diagram of the principle structure of the dispensing height compensation device of the present invention, and the dispensing height compensation device includes a camera module 1, a processing module 2 and a dispensing module 3;

[0041] The camera module 1 is used to randomly take three reference points on the first product to be dispensed and the second product to be dispensed respectively, construct a reference plane α and a reference plane β, and take P2 as the vertical line of the reference plane α, Intersect the reference plane α at point P3, where there is a dispensing position P1 on the reference plane α, and a dispensing position P2 on the reference plane β, and the dispensing positions P1 and P2 are on the product to be dispensed The same position; Optionally, the product to be dispensed is a plane dispensed product.

[0042] The processing module 2 is used to measure the distance h between the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com