Heat dissipation structure of preheating chamber roller bed

A technology of heat dissipation structure and preheating chamber, applied in the direction of roller table, used abrasive treatment device, abrasive material, etc., can solve the problems affecting the normal conveyance of steel plates and the deformation of the roller table.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The heat dissipation structure of the roller table in the preheating chamber of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

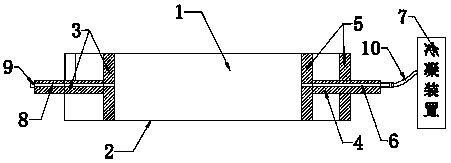

[0010] As shown in the figure, the heat dissipation structure of the roller table in the preheating chamber of the present invention includes a roller table body 1 located in the preheating chamber. The roller table body 1 includes a drum 2 and two sealing end covers 3 on the left and right sides of the drum. Each sealing end cover 3 includes a rotating shaft 4 and a mounting plate 5 installed on the rotating shaft. There are two mounting plates 5, and the two mounting plates 5 are arranged side by side on the rotating shaft. The sealing plate 5 positioned on the outside is welded and fixed on the drum 2. On the side end face of one of the rotating shafts 4, a through hole 6 is provided in the center of the rotating shaft 4, and an exhaust hole 8 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com