Dual clutch with drive ring optimized for removal

A dual clutch and tool technology, applied in mechanical drive clutches, clutches, friction clutches, etc., can solve the problems of accidental deformation of the driving member, plastic deformation of the annular tooth area, etc., and achieve the effect of reducing the radial size and being easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

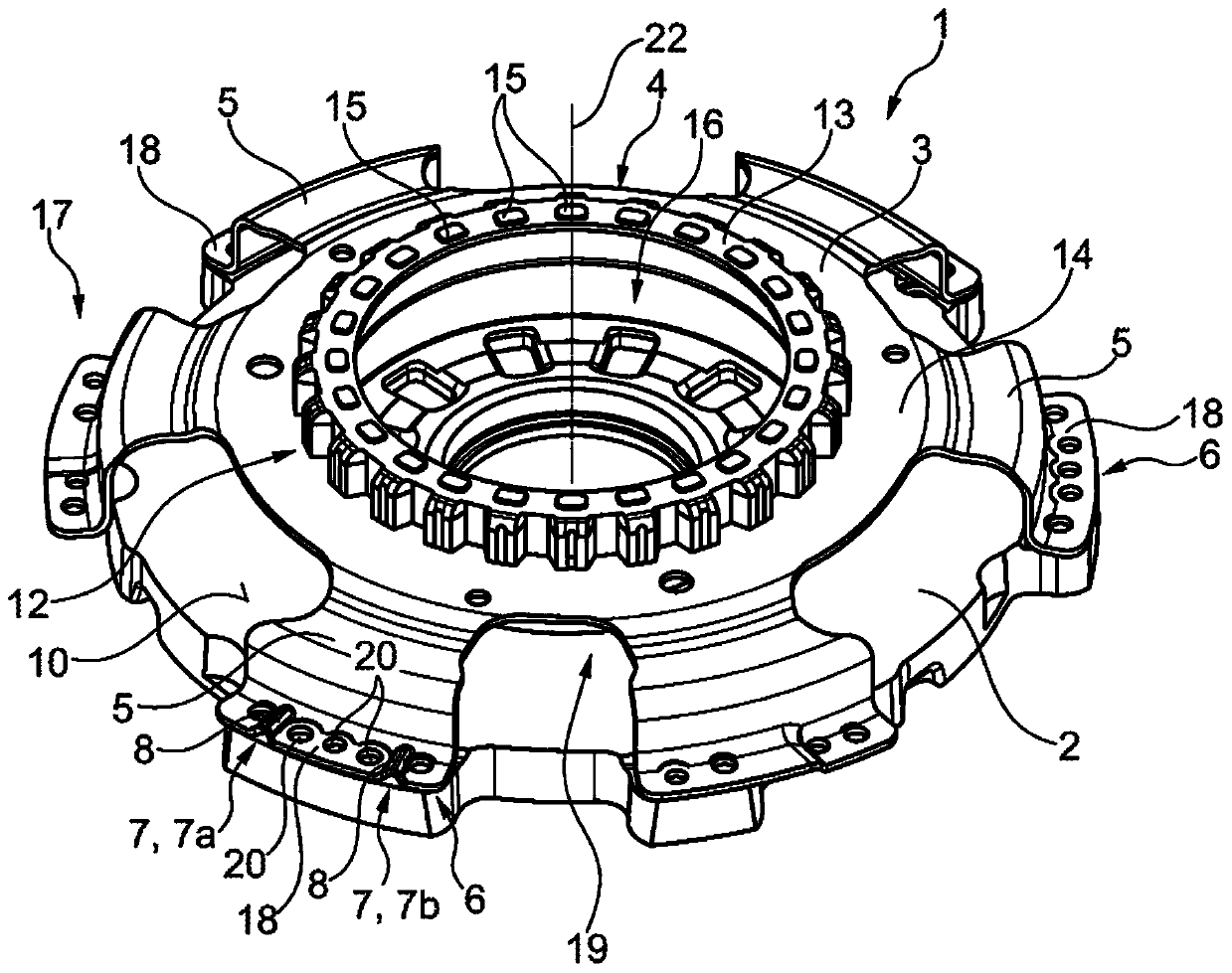

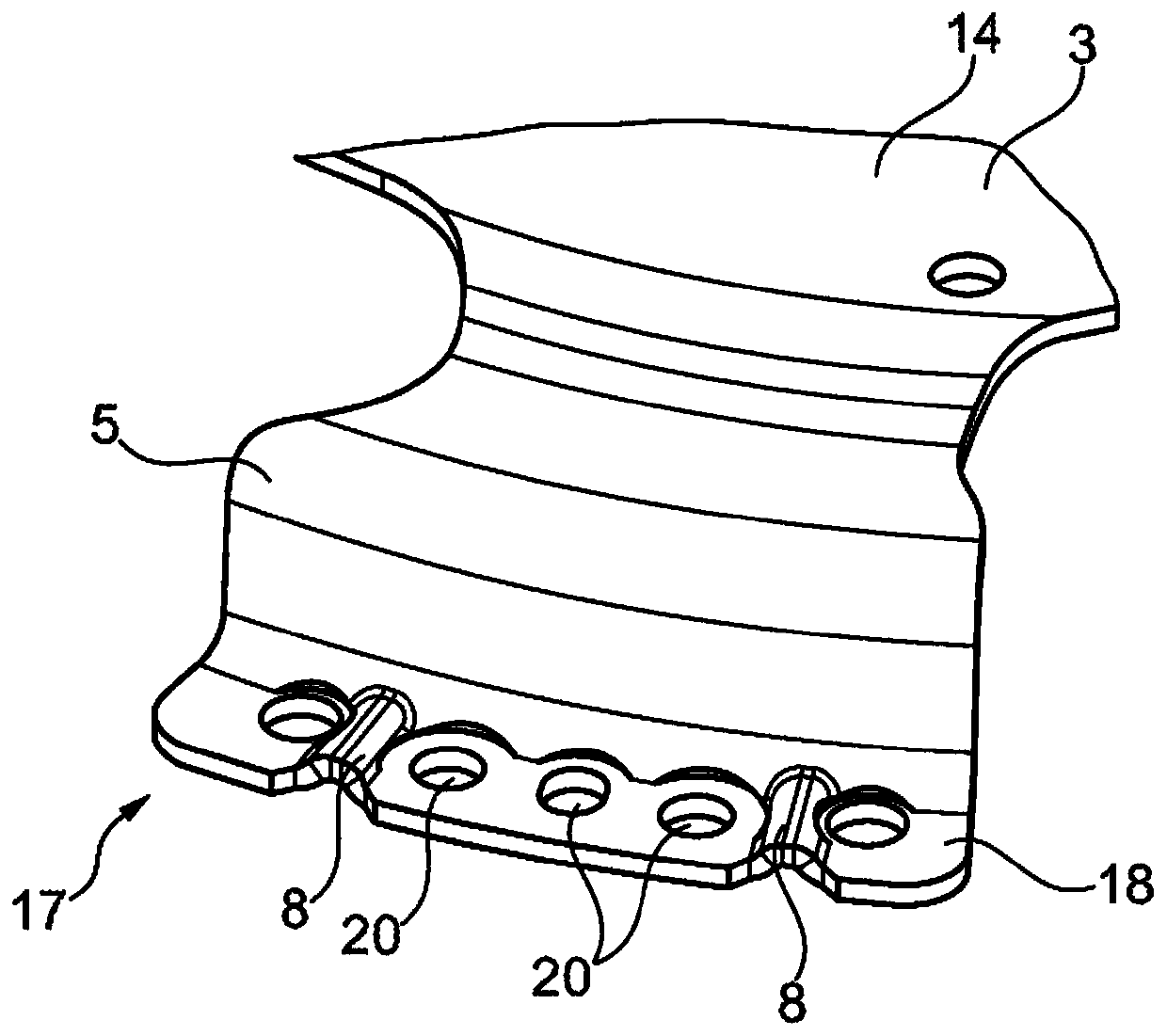

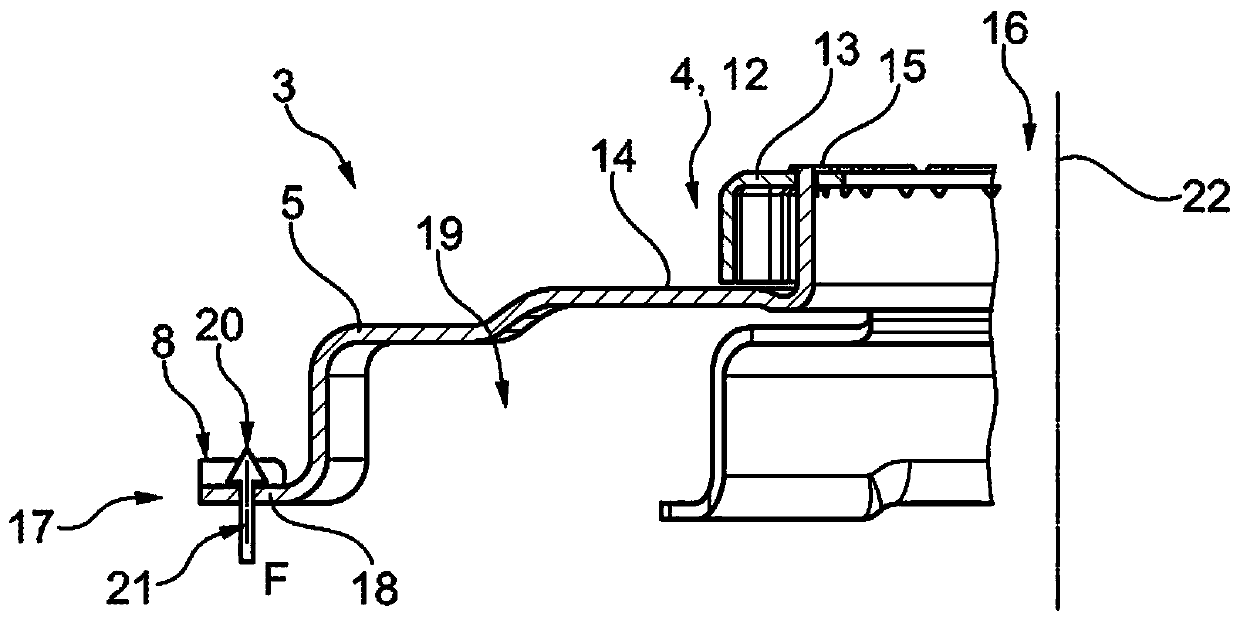

[0029] figure 1 The central plate-entraining member-assembly 1 of the double clutch according to the invention is shown. For the sake of clarity, the dual clutch according to the invention is only shown in the region of the assembly 1, wherein the dual clutch is as far as possible in the usual manner as the known dual clutch, which has been disclosed, for example, by DE 10 2005 037 514 A1 construction and operation. The torque transmission device of DE 10 2005 037 514 A1 is therefore considered to be integrated in this other embodiment of the dual clutch, which is not shown here for the sake of clarity. The dual clutch according to the invention is therefore also conventionally designed as a separable coupling element for a drive train of a motor vehicle and is accommodated during operation in the torque flow between the internal combustion engine and the transmission.

[0030] The shown central plate-entraining component assembly 1 has a central plate 2 and an entraining co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com