Intelligent lightning protection system of power transmission line

A lightning protection system and transmission line technology, applied in the field of lightning arresters, can solve the problems of falling, many operation procedures, erosion, etc., and achieve the effects of strong practicability, convenient use and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

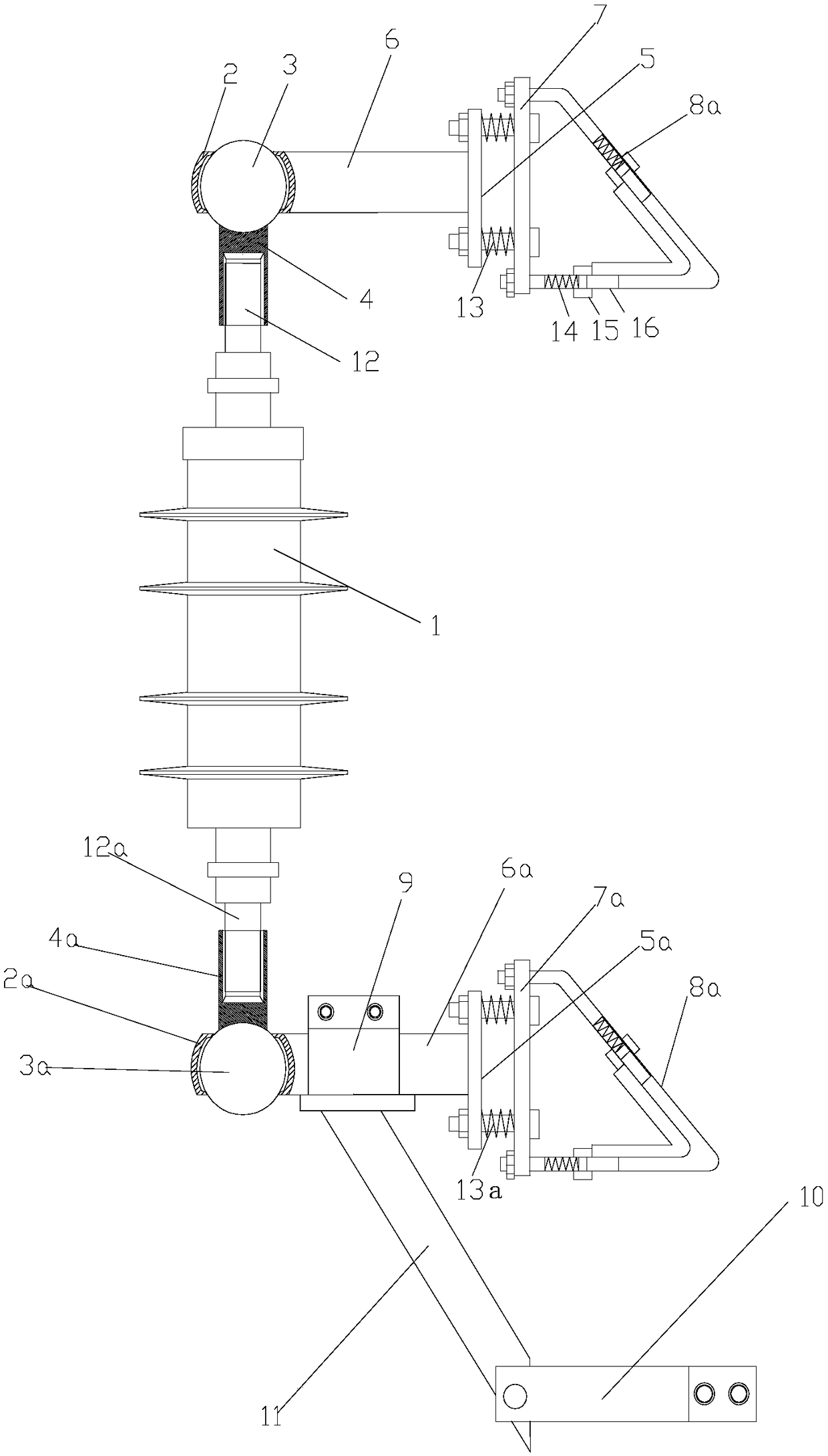

[0014] As shown in the figure: the transmission line intelligent lightning protection system of this embodiment includes a lightning arrester body 1 and an upper connection assembly and a lower connection assembly respectively used to connect the upper and lower ends of the lightning arrester body 1 and the pole cross arm, the upper connection assembly and the lower connection assembly. The components have the same structure, and both at least include an outer ball bag (outer ball bag 2 and outer ball bag 2a in the figure), a sphere movably connected with the outer ball bag (ball 3 and sphere 3a in the figure) and a 1 vertical connecting arm (vertical connecting arm 4 and vertical connecting arm 4a in the figure) with threaded ends, vertical connecting arm 4 is fixedly connected to sphere 3, vertical connecting arm 4a is fixedly connected to sphere 3a, and sphere It can be fixedly connected with the vertical connecting arm by welding, and can also be integrally formed, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com