A method for measuring the channel diffusion factor of porous materials

A determination method and technology of porous materials, applied in the field of preparation of porous materials, can solve the problem of not being able to characterize and measure the degree of pore tortuosity and the degree of restriction of molecular diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: the synthesis of reference sample

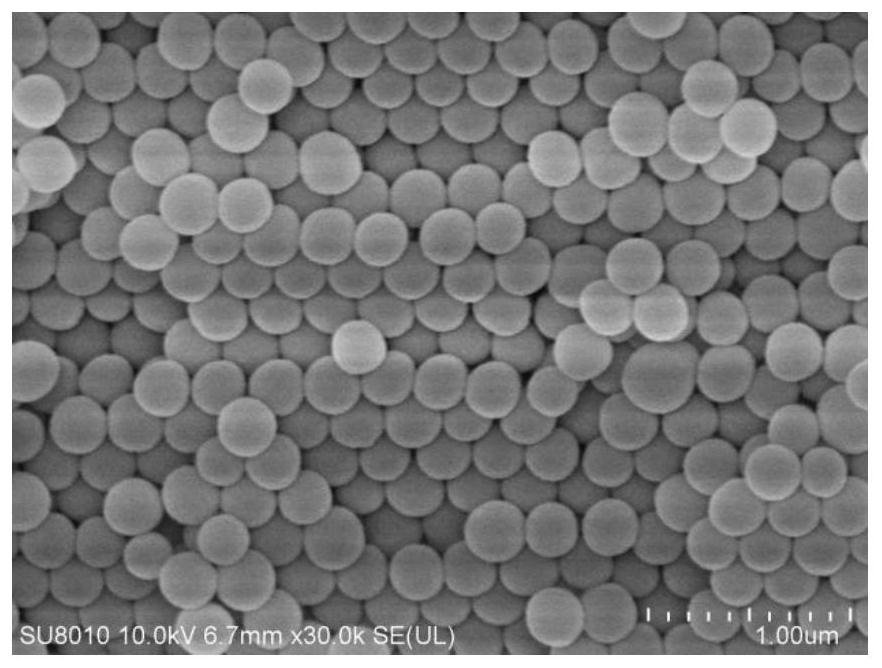

[0082] The porous material reference sample of the present invention is the Al of surface Al modification 2 o 3 / SiO 2 Opal, the synthesis process is as follows:

[0083] Add 504mL of ethanol, 130mL of water and 40mL of ammonia water with a mass fraction of 25% in a 2000mL three-necked flask. Then 0.333 g of silica sol with a solid content of 30% by weight and an average particle diameter of about 30 nm was added to a three-necked flask, and the temperature of the reaction solution was controlled at 30°C. Then, under the state of mechanical stirring, the mixed solution prepared by 61mL concentration of 25% by weight ammonia, 35mL water and 104mL ethanol was added dropwise, and the mixed solution prepared by 163mL tetraethyl orthosilicate and 37mL methanol was added dropwise. for 3 hours. Continue to react for 2 hours after the dropwise addition, then centrifuge, wash with water and separate to obtain ~300nm monodisp...

Embodiment 2

[0086] Embodiment 2: the preparation of different solute concentration solutions

[0087] Take 2000g of n-octane and 2000g of mesitylene, mix them evenly, add 2,6-lutidine to it, and prepare a solution with a concentration of 2,6-lutidine of 1000ppm, which will be used as a solvent for the diffusion experiment and set aside.

[0088] Take five parts of the above-mentioned solvents, 100 g each, and add dibenzothiophene (DBT) therein to prepare standard solutions with DBT concentrations of 20 ppm, 30 ppm, 40 ppm, 60 ppm, and 80 ppm respectively for future use.

[0089] Take 900g of the above-mentioned solvent, add DBT thereinto, and make a diffusion solution with a DBT concentration of 5000ppm for future use.

[0090] Take 150g of each of the above four solvents, add DBT therein, and prepare adsorption solutions with DBT concentrations of 1000ppm, 3000ppm, 7000ppm, and 9000ppm, respectively, for future use.

Embodiment 3

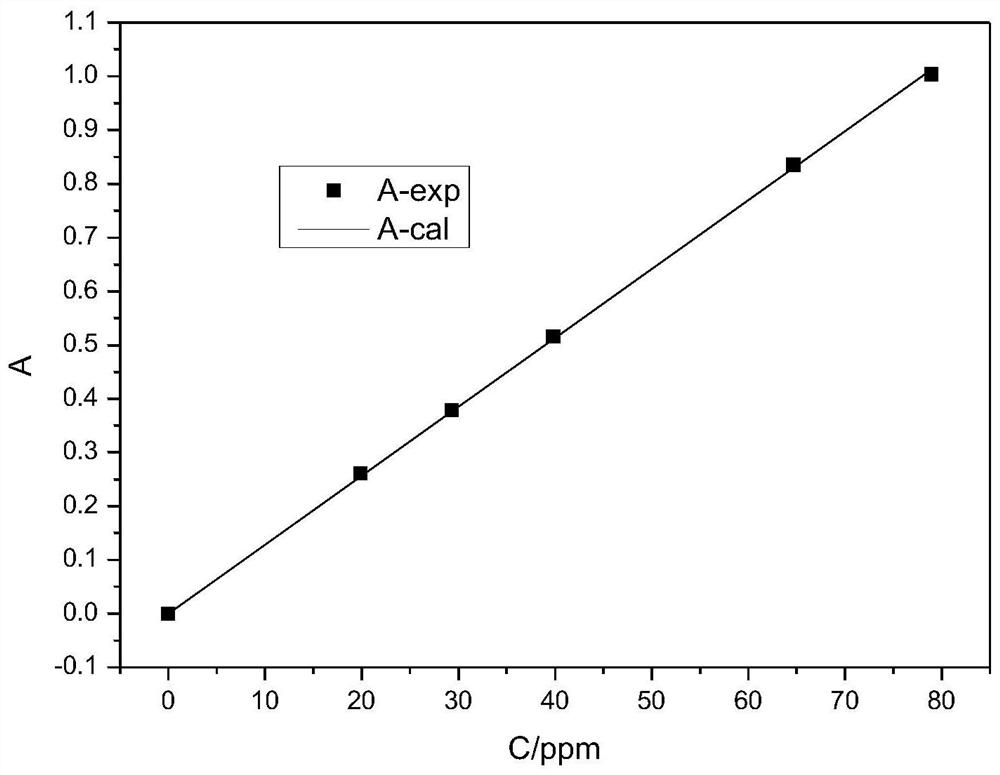

[0091] Example 3: Creation of Calibration Curve for Dibenzothiophene UV Absorbance

[0092] Measure the absorbance A at 327nm of DBT standard solutions with different concentrations. Plot the DBT concentration (C A ) and absorbance (A) curve, see figure 2 . C A It has a good linear relationship with A, and its linear equation (that is, the DBT ultraviolet absorption calibration curve) is A=0.012832C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diffusion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com