Variable-geometry supersonic velocity combustion chamber

A technology of supersonic combustion chamber and combustion chamber, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of difficult sealing, complex structure, design of fixing device and cooling structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

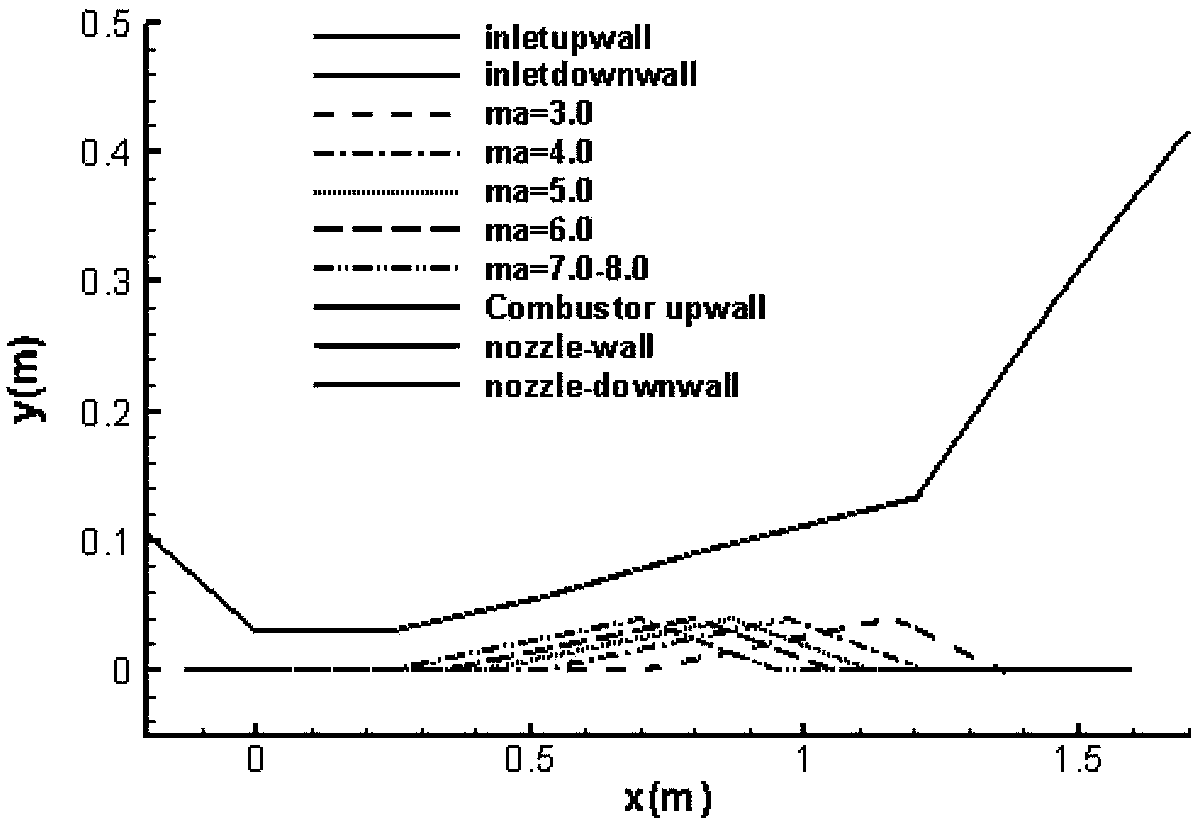

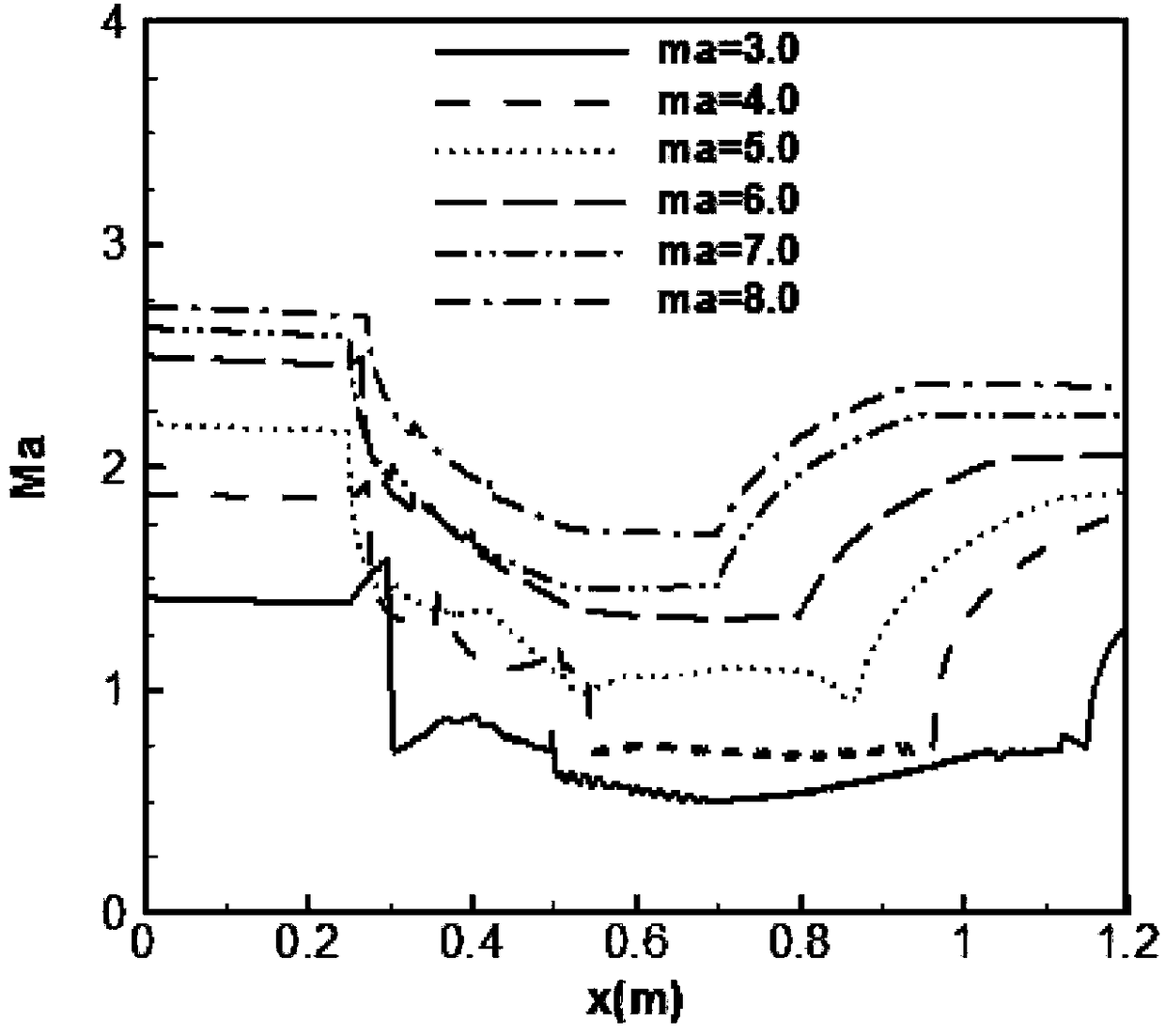

[0019] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The geometry of the combustion chamber is all expansion type within the range of Mach number 3.0-8.0. When the incoming flow velocity is lower, such as when the flight Mach number is 3.0, the center body on the lower wall is located at the rear of the combustion chamber, and there is a large expansion space between the center body and the isolation section. Due to the pressure increase caused by combustion in the combustion chamber, the airflow passes through the intake port and forms a normal shock wave in the isolation section. After the normal shock wave, the airflow decelerates to subsonic speed, and the combustion chamber is in a sub-combustion mode. The gas flow is accelerated to supersonic speed through the thermodynamic throat at the corner of the center body. At low flight Mach number, the center body of the lower wall is located in the rear position, so that there is a large expansion space for the combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com