Automatic feeding mechanism of 3D hot bending machine

A technology of automatic feeding and hot bending machine, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., to avoid influence, ensure product quality consistency, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

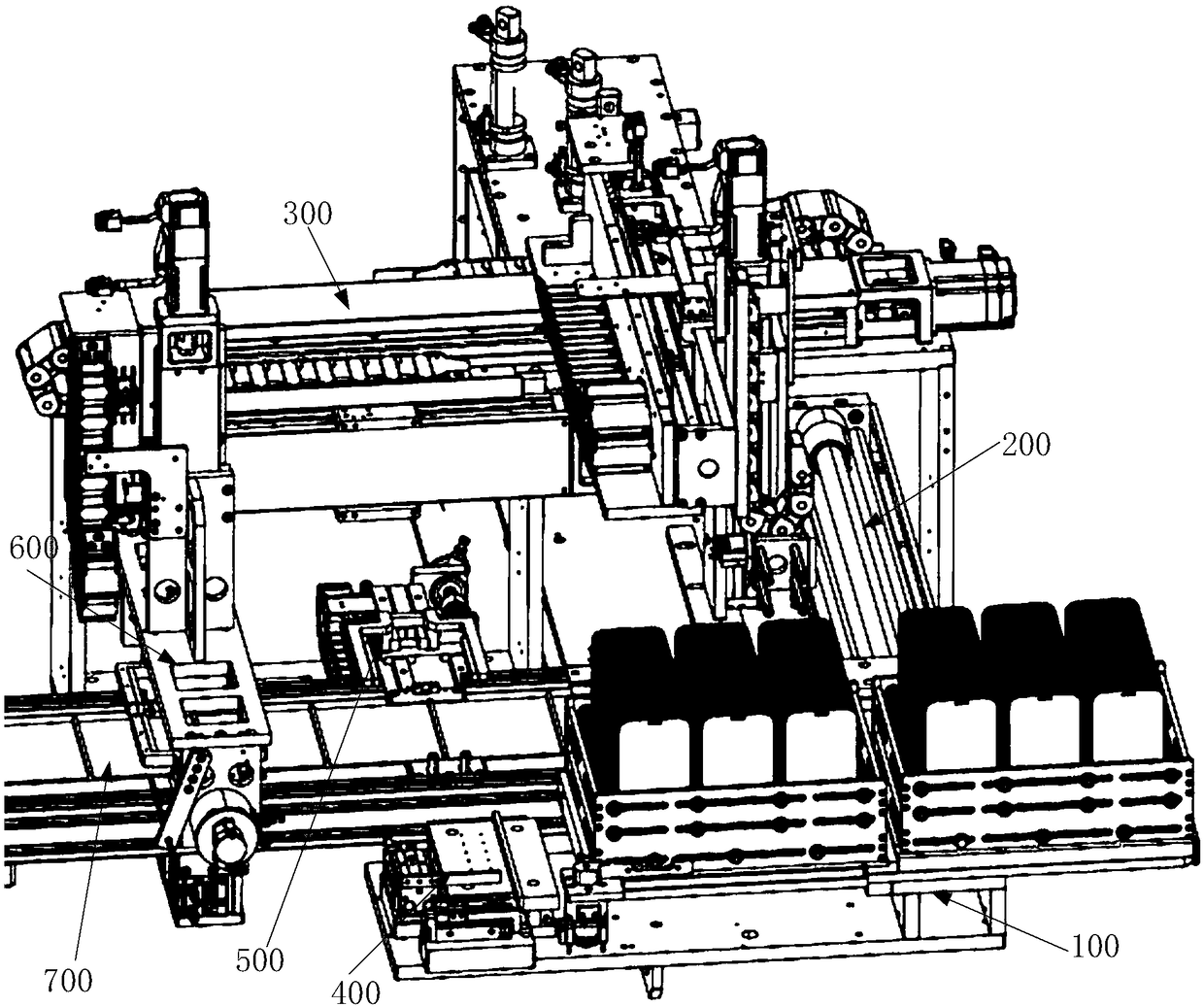

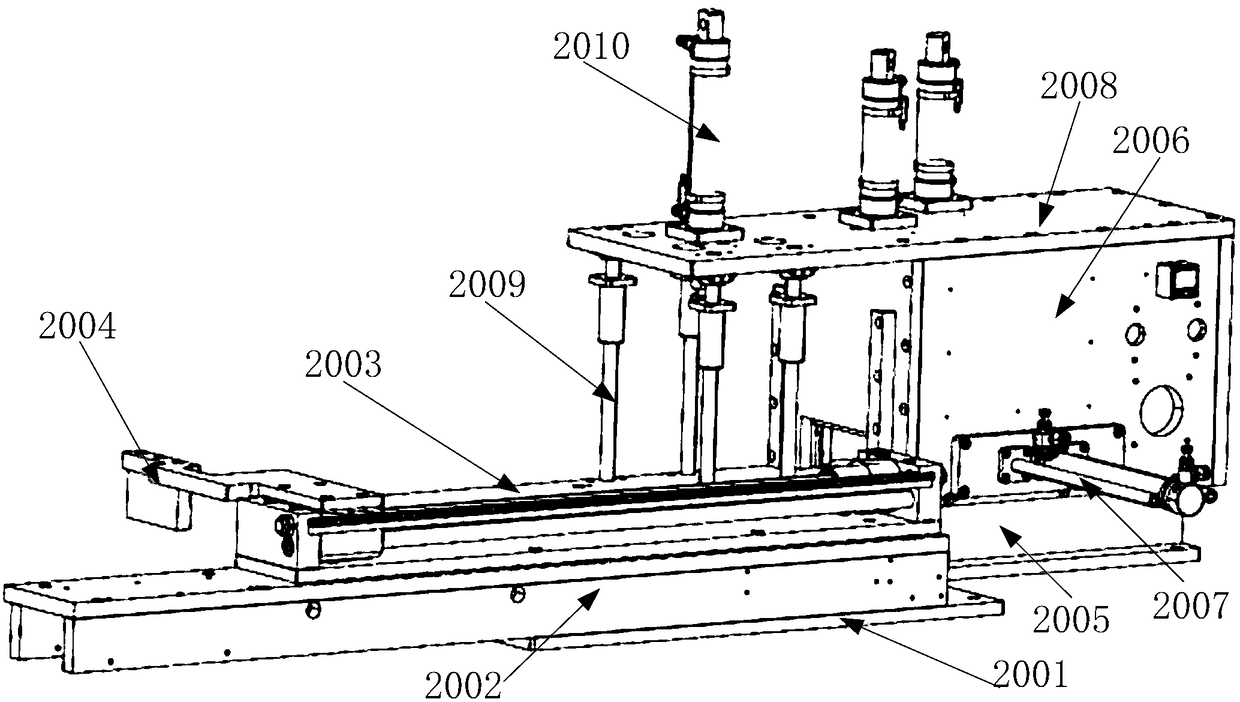

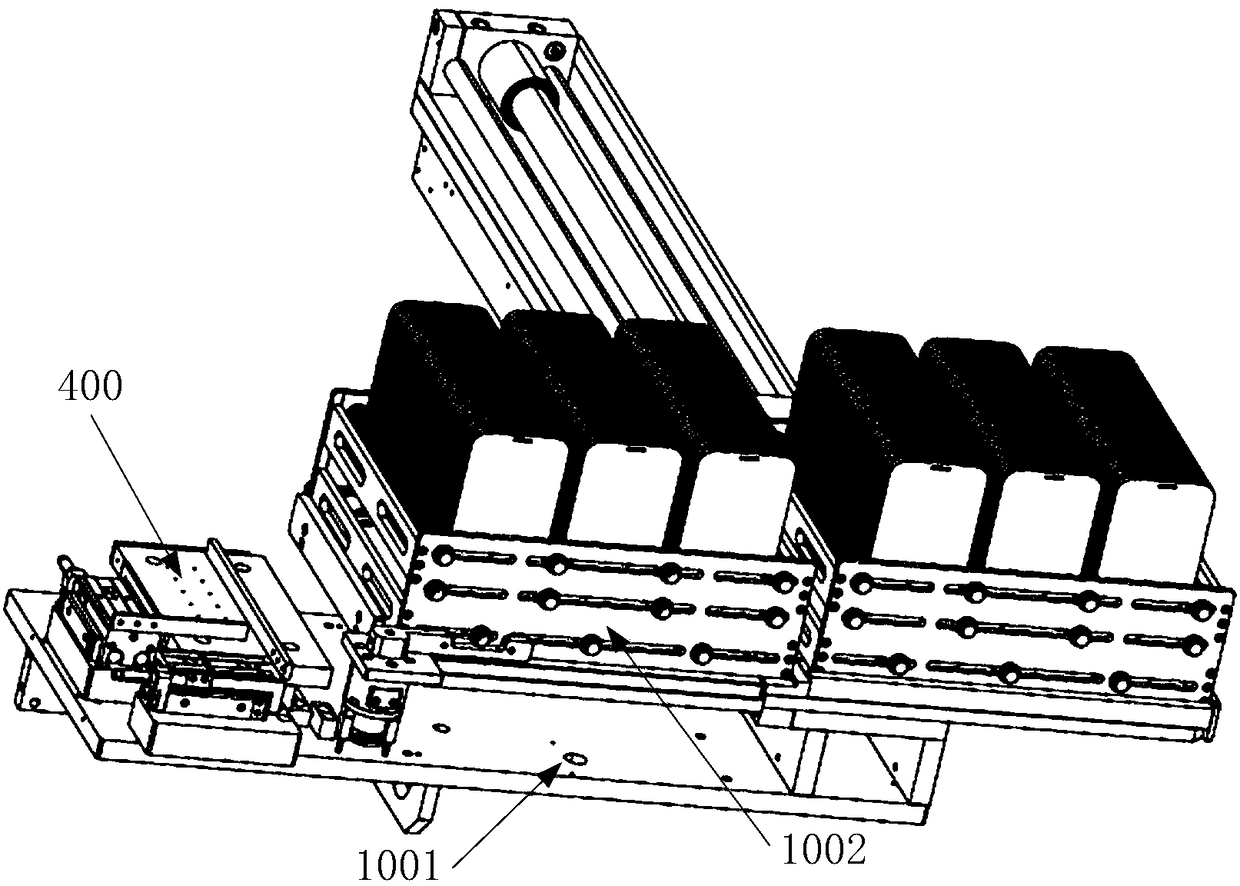

[0023] Reference signs: 100-glass tray assembly 200-feeding toggle assembly 300-retrieving manipulator assembly 400-glass secondary positioning assembly 500-lower mold positioning assembly 600-upper mold positioning pick-and-place assembly 700-mold conveyor belt line Component 1001-feed tray bracket 1002-feed tray 2001-toggle bottom plate 2002 screw bracket 2003-ball screw 2004-toggle piece 2005-toggle bracket 2006-toggle seat 2007-pneumatic mechanism 2008-toggle plate 2009- Connecting pillar 2010-cylinder 3001-feeding manipulator bracket 3002-manipulator 3003-X-axis retrieving motion mechanism 3004-Y-axis retrieving motion mechanism 3005-Z-axis retrieving motion mechanism 4001-positioning seat 4002-first limit seat 4003 -Second limit seat 4004-First positioning plate 4005-Second positioning plate 5001-Guide rail 5002-Slider 5003-Cylinder connecting plate 5004-Cylinder 5005-Lower mold positioning claw 6001-X-axis upper mold pick-and-place movement mechanism 6002 - Z-axis upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com