Forklift work safety control system

A safety control and forklift technology, applied in the direction of lifting equipment safety devices, lifting devices, etc., can solve the problems of falling goods, safety accidents, falling damage, etc., and achieve the effect of protecting the safety of operators and goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

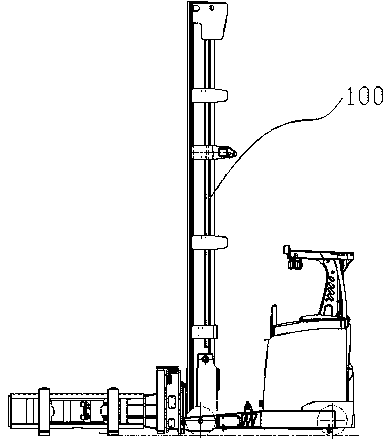

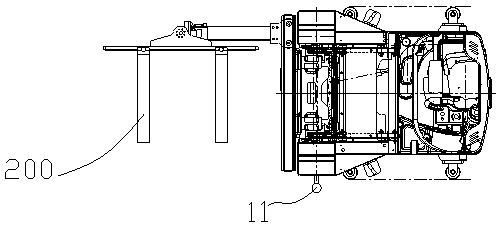

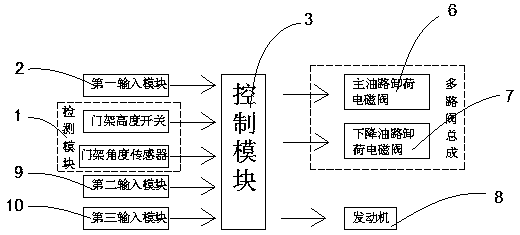

[0051] Embodiment 1: The present invention provides a forklift work safety control system, which is installed in the forklift control room, and is used to control the work of the forklift mast tilt angle data adjustment hydraulic subsystem, including: detection module 1, hydraulic subsystem 4, control Module 3 and the first input module 2, the control module is respectively connected to the detection module, the hydraulic subsystem and the first input module; the detection module is used to collect data on the height of the mast or the inclination angle of the mast and transmit it to the control module Among them: the hydraulic subsystem is used to receive instructions from the control module to drive the lifting of the mast 100 or adjust the inclination angle of the mast; the first input module is used to provide a signal for adjusting the leveling of the forklift or a normal operation mode signal; When the first input module gives a signal to adjust the leveling of the forkli...

Embodiment 2

[0053] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention provides a forklift work safety control system, which is installed in the forklift control room, and is used to control the work of the forklift gantry tilt angle data adjustment hydraulic subsystem, including: detection module 1, hydraulic subsystem 4, control module 3 and the first input module 2 . Wherein, the detection module is used to collect the data of the height of the mast or the data of the inclination angle of the mast and transmit it to the control module; the detection module includes a mast height switch 3-3 and a sensor for the inclination angle of the mast 4-3. The hydraulic subsystem is used to receive instructions from the control module to drive the lifting of the mast or adjust the inclination angle of the mast; the hydraulic subsystem also includes a main oil circuit, a descending circuit and a multi-way valve assembly 5-3. The circuit va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com