Automatic die switching device for injection molding machine

An automatic mold changing and injection molding machine technology, applied in the field of automatic mold changing device and automatic mold changing device of injection molding machine, can solve the problems of unclean finished product, reduced mold service life, large mold deformation and wear, etc., and achieves convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

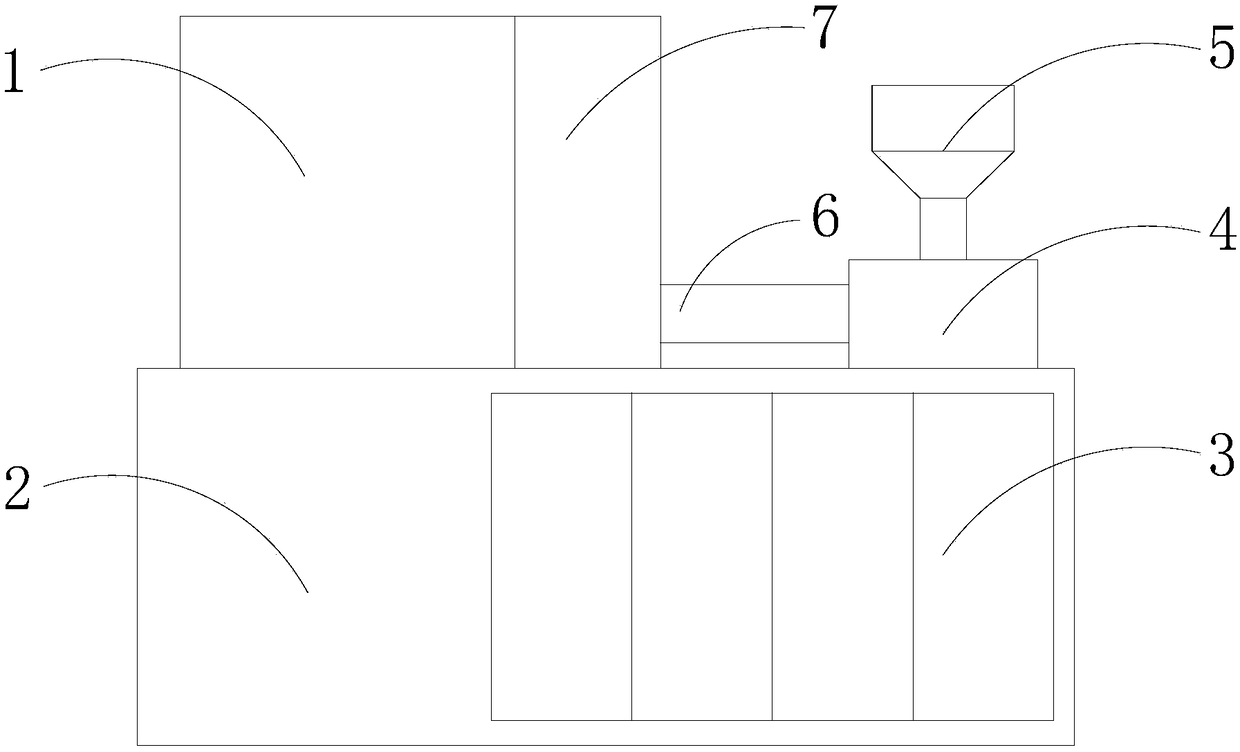

[0024] see Figure 1-Figure 5, the present invention provides an automatic mold changing device for an injection molding machine. 1. The lower surface is fixedly installed on one end of the base 2. The base 2 and the cabinet 3 are an integrated structure. The propeller 4 is installed on the other end of the base 2. The lower end of the feeding hopper 5 is installed on the propeller 4. The propeller 4 is connected to the head end of the feed pipe 6 , and the end of the feed pipe 6 is connected to the mold clamping host 7 , and the mold clamping host 7 is connected to the mold changing host 1 .

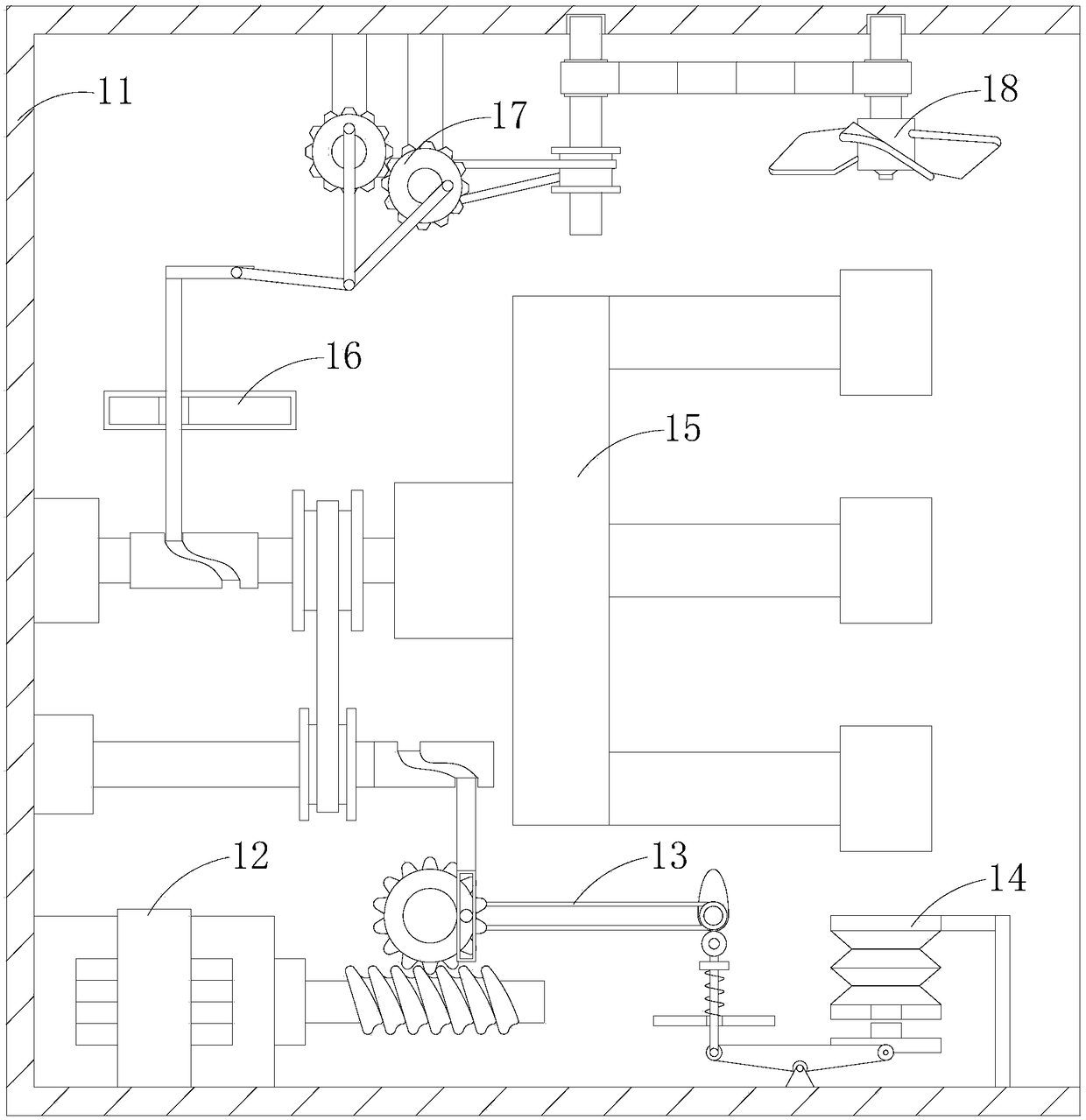

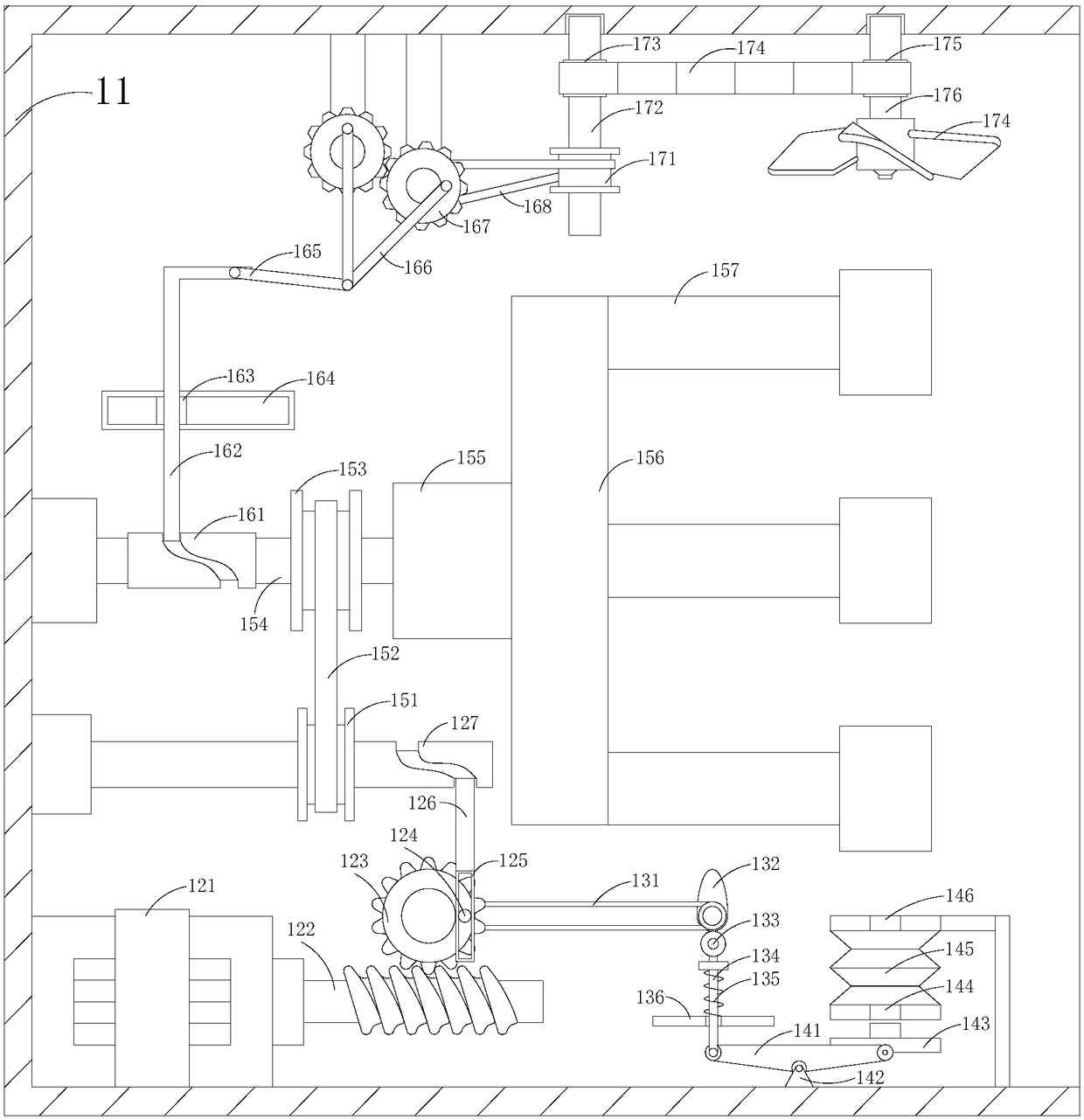

[0025] The mold changing host 1 includes a housing 11, a power mechanism 12, a pressing mechanism 13, a dust removal mechanism 14, a rotating mold changing mechanism 15, a driving mechanism 16, and a cooling mechanism 17. The lower surface of the housing 11 is fixedly mounted on one end of the base 2, The power mechanism 12 is fixedly installed on the inner bottom surface of the shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com