Sensory control automatic conveying equipment for smart car motor paint immersion

A technology of automatic conveying and sensor control, which is applied to devices for coating liquid on surfaces, pretreatment surfaces, coatings, etc., can solve problems such as high labor costs, and achieve the effect of reducing labor costs and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

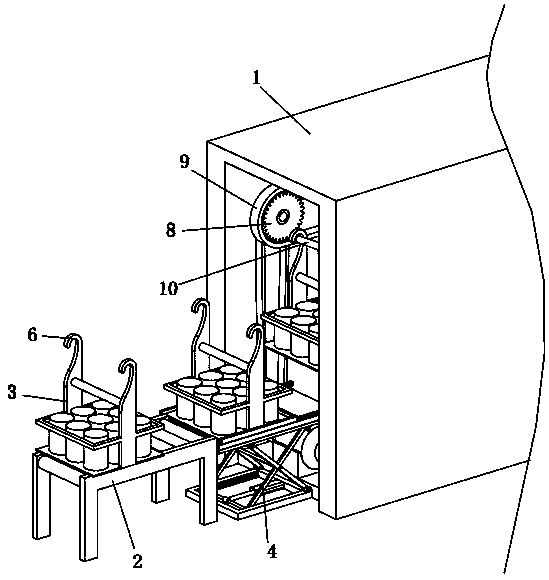

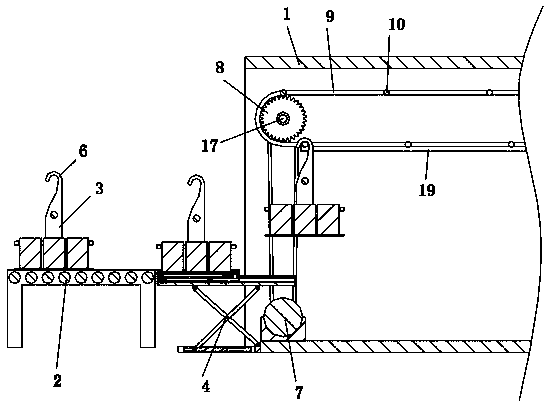

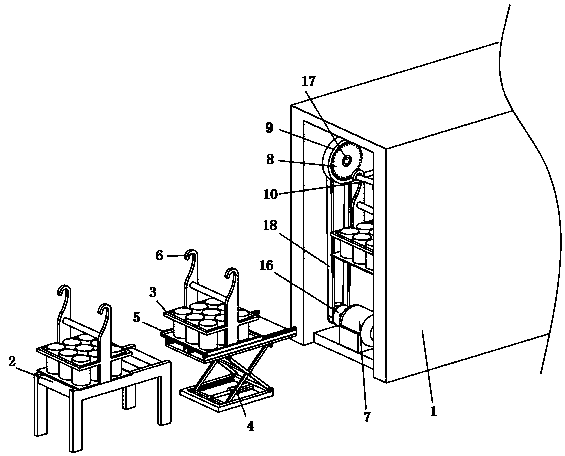

[0021] refer to Figure 1 to Figure 5 The sensor-controlled automatic conveying equipment for smart car motor dipping shown includes a vacuum continuous immersion machine. The vacuum continuous immersion machine includes a drying tunnel 1, and also includes a motor conveyor belt 2, a motor holding frame 3, and a lifting device 4 and the transmission assembly, the transmission assembly is arranged inside the drying tunnel 1, the lifting device 4 is arranged at the entrance of the drying tunnel 1, the motor conveyor belt 2 is arranged on the side of the lifting device 4 away from the drying tunnel 1, and the top of the lifting device 4 is provided with The translation assembly, the translation assembly includes a translation plate 5 that can move horizontally on the top of the lifting device 4, the motor holding frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com