A kind of metal gel electrolyte and preparation method thereof

A metal gel and electrolyte technology, used in capacitor electrolytes/absorbers, electrolytic capacitors, circuits, etc., can solve the problems of poor ionic conductivity, difficult battery packaging, volatile electrolyte leakage, etc., and achieve high-efficiency photoelectric performance, material Rich, easy-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of the metal gel electrolyte: Weigh 18 mg of tannic acid, 20 mg of bis(acetylacetonate) diisopropyl titanate and 0.45 ml of dimethylformamide in a sample bottle, disperse them by ultrasonication for 20 min, and then statically Let it stand for 1 hour to form a metal gel, and then add 0.8ml of liquid electrolyte to the metal gel. After 1 day of adsorption, pour out the unabsorbed liquid electrolyte, and the metal gel electrolyte is in the sample bottle. The liquid electrolyte includes: 1mol / L 1,3-dimethyl-3-imidazolium iodine (DMII), 0.1mol / L lithium iodide, 0.13mol / L guanidine thiocyanate, 0.11mol / L iodine, 0.7mol / L4-tert-butylpyridine, the solvent is a mixed solution of acetonitrile and valeronitrile with a volume ratio of 85:15.

Embodiment 2

[0032] Fabrication of quasi-solid-state dye-sensitized solar cells based on metal gel electrolytes:

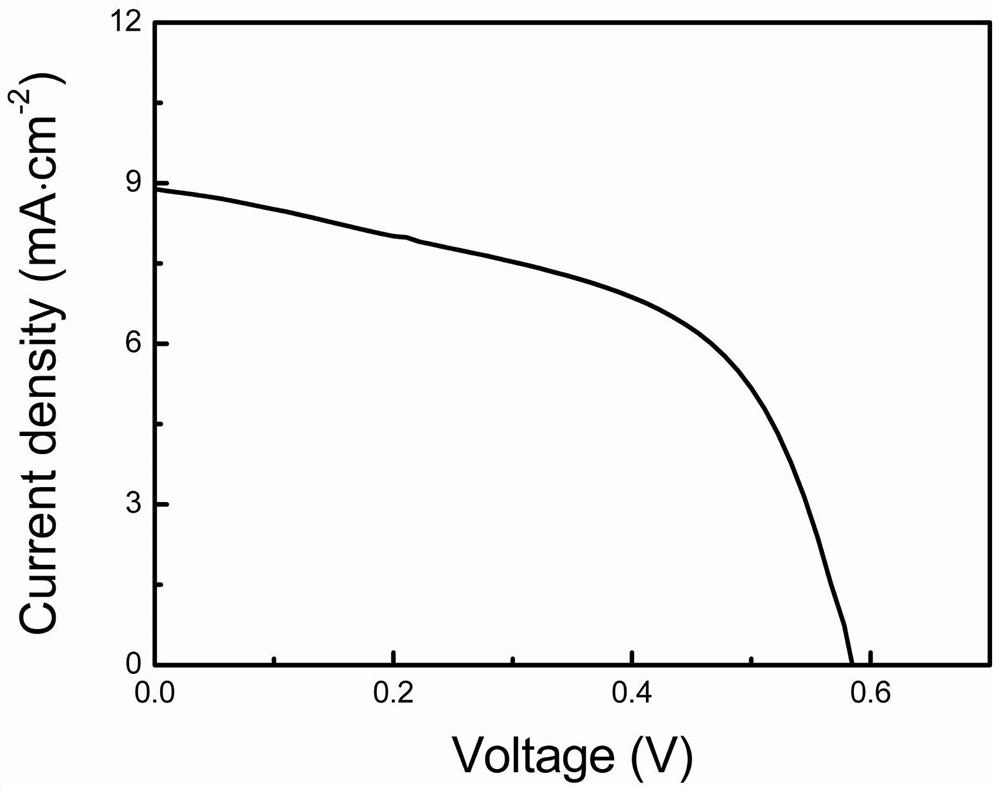

[0033] TiO2 was screen-printed 2 Nanoparticles are printed on the cleaned FTO conductive glass, and its thickness is controlled to be about 11 μm. It is heat treated in a programmed temperature muffle furnace at 510 ° C for 30 minutes. After cooling to room temperature, it is soaked in 30 mMTiCl at 70 ° C. 4 20min in aqueous solution, then sintered at 510°C for 30min at high temperature, and when cooled to 120°C, soak it in N719 dye for 16 hours, then take it out to get a photoanode that adsorbs N719 dye. Coat another piece of cleaned FTO conductive glass with isopropanol solution containing chloroplatinic acid, calcinate at 410°C for 30min, and cool to room temperature to obtain a Pt-containing counter electrode. Finally, the metal gel electrolyte is placed between the photoanode and the counter electrode by a sandwich method to assemble a battery. Such as figure 1 Shown a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com