Bridge deck filling equipment

An equipment and end face technology, applied in the field of bridge deck filling equipment, can solve the problems of affecting the efficiency of watering and filling, slowing down the filling progress, and large labor force, so as to reduce the amount of manual labor, improve the uniformity, and reduce the labor force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

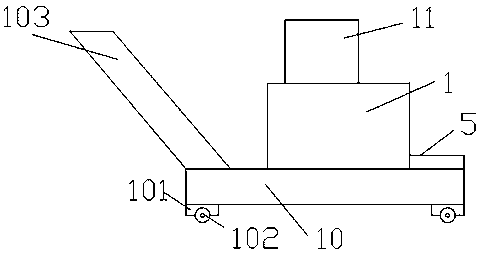

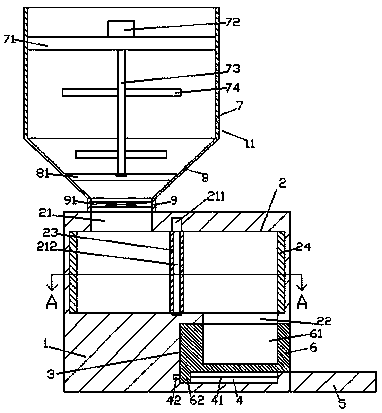

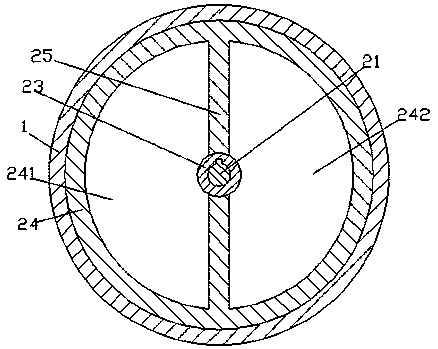

[0022] Such as Figure 1-Figure 7 As shown, a bridge deck filling device of the present invention includes a base plate 10, a round platform 1 arranged above the base plate 10, and a bucket 11 arranged above the round platform 1, and four corners of the bottom of the base plate 10 are provided with There is a corner post 101, the bottom of the corner post 101 is provided with rollers, the left side of the bottom plate 10 is fixedly connected with a handle 103, so as to realize the convenience of moving or carrying, the top end surface of the bottom plate 10 and the bottom end surface of the bucket bin 11 Fixedly connected, the bucket bin 11 includes a first bucket portion 7, a second bucket portion 8 arranged at the bottom of the first bucket portion 7, and a third bucket portion 9 arranged at the bottom of the second bucket portion 8, so The inside of the round platform 1 is provided with a first chamber 2, the top of the left side of the first chamber 2 is provided with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com