A method for controlling the drying process of materials in a drying room based on the calculation of accumulated temperature

A drying process and accumulated temperature technology, which is applied in the direction of drying solid materials, drying, lighting and heating equipment, etc., can solve the problems of poor accuracy and low degree of automation, and achieve the goal of ensuring quality, improving precision and stability, and reducing complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

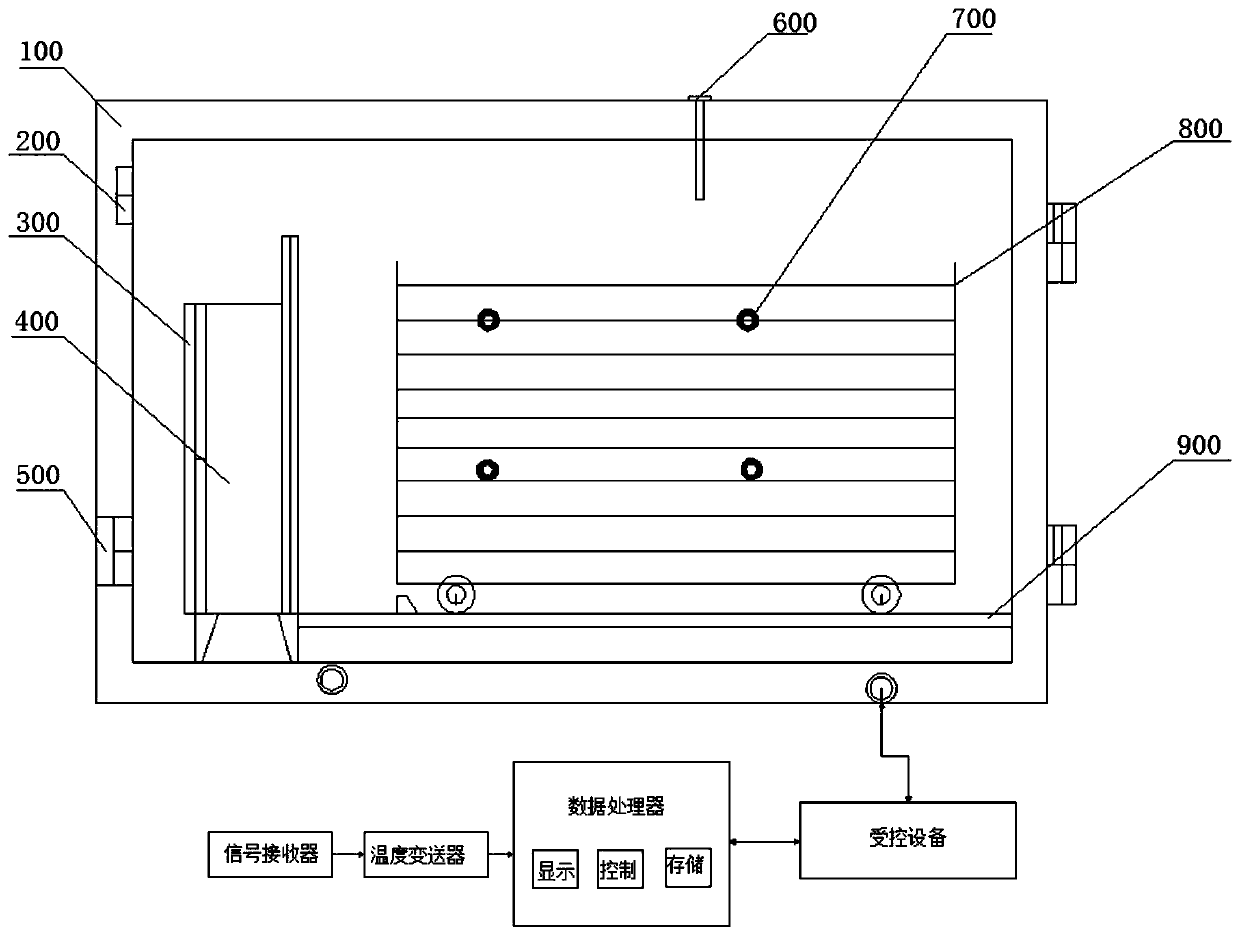

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

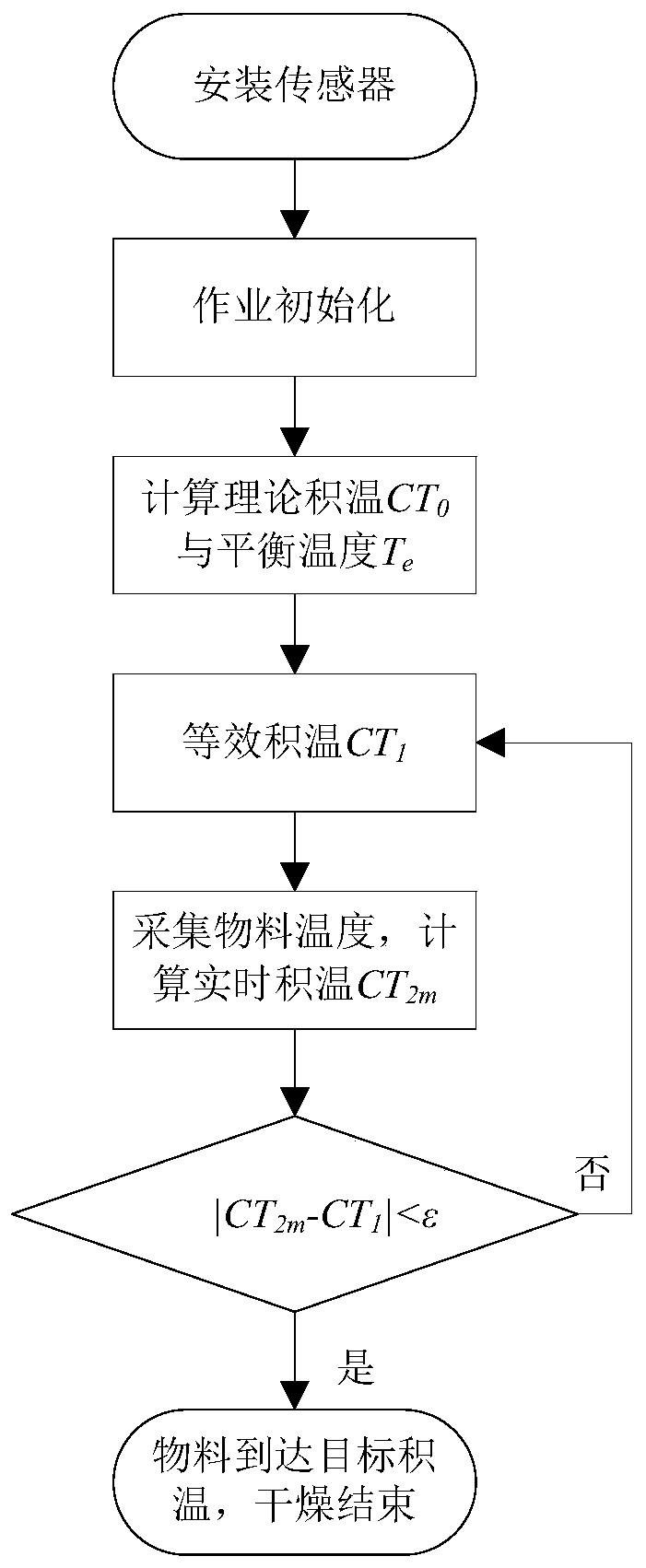

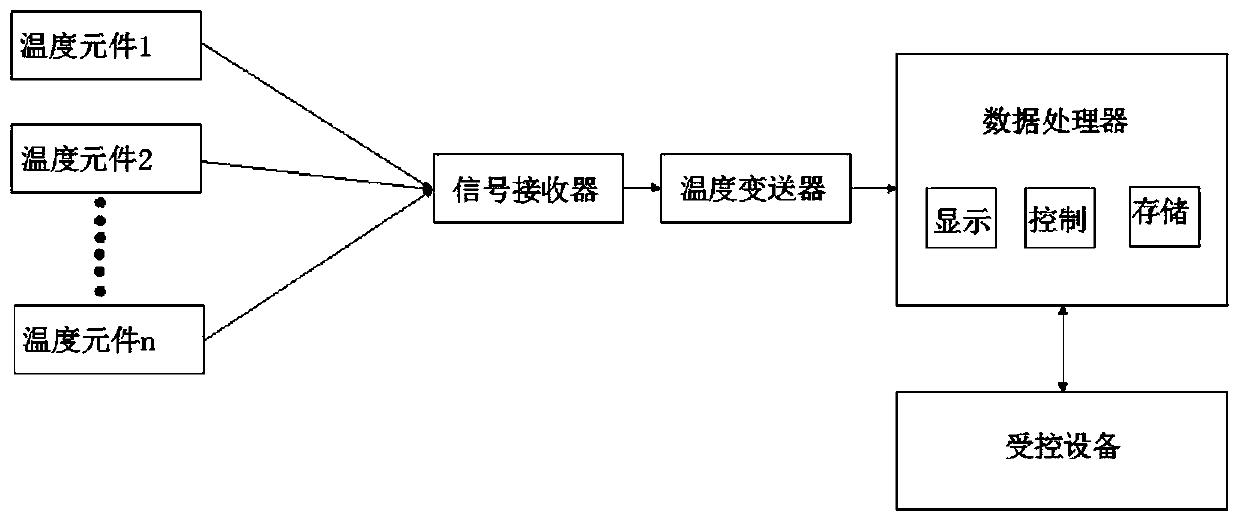

[0036] Such as figure 1 As shown, the present invention provides a method for controlling the drying process of materials in a drying room based on accumulated temperature calculation, including: Step 1. During the process of loading materials, a plurality of temperature acquisition elements are synchronously arranged in the trolley for loading materials, so that the The temperature collection element is submerged in the material, and the trolley is pushed into the drying position.

[0037] Step 2. Select the theoretical accumulated temperature calculation model and the equilibrium temperature calculation model, and set the temperature acquisition period t a , Accumulated temperature control accuracy ε, Accumulated temperature correction coefficient K 0 .

[0038] Step 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com