Self-decompression gas distribution mechanism and low-temperature refrigerator adopting the self-decompression gas distribution mechanism

A technology of low-temperature refrigerators and gas distribution mechanisms, which is applied to gas cycle refrigerators, refrigerators, compressors, etc., can solve problems such as large positive pressure, wear of rotary valves, and reduced reliability of equipment, so as to reduce positive pressure and prolong Service life, effect of reducing plane wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

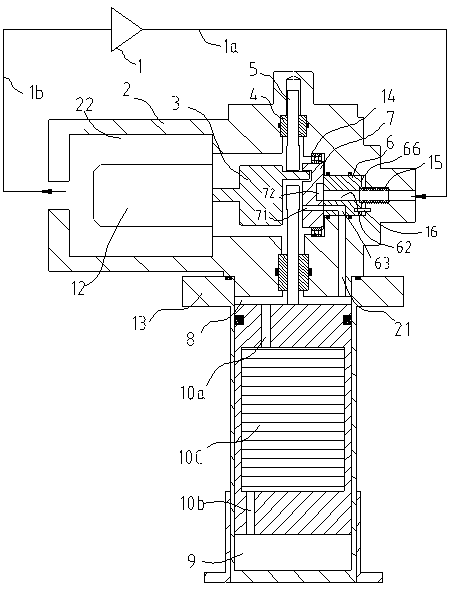

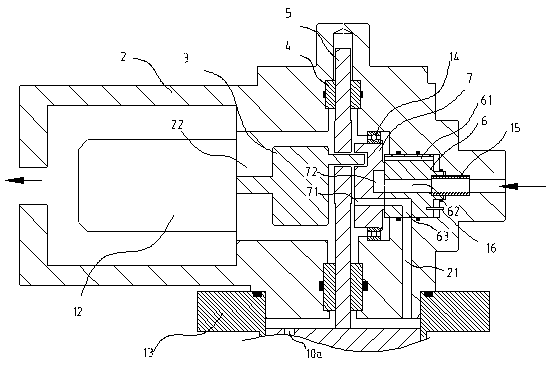

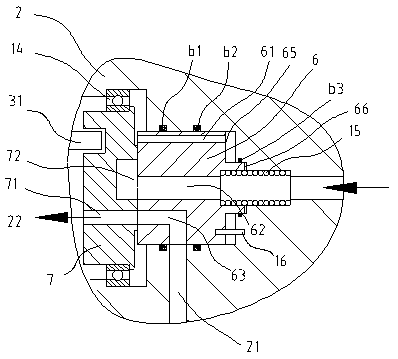

[0027] Such as Figure 2-7 As shown: a self-decompression gas distribution mechanism, including a gas distribution valve 6 and a rotary valve 7. The gas distribution valve 6 is provided with a high-pressure air hole 62 penetrating the gas distribution valve 6 in the axial direction, and penetrating the gas distribution valve in the bending direction. 6, the gas distribution valve hole 63, the high-pressure gas hole 62 can communicate with the high-pressure exhaust pipeline 1a of the compressor 1, and the gas distribution valve hole 63 can communicate with the cover body gas hole 21 on the cover body 2; The high-pressure groove 72 on the valve 7 communicates with the air distribution valve air hole 63 and the housing air hole 21; The circumferential surface of the gas distribution valve 6 is provided with a first sealing ring b1 and a second sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com