Rail vehicle air-conditioning duct pipe and preparation method thereof

A technology for air-conditioning air ducts and rail vehicles, which is applied in the heating/cooling of railway vehicles, railway car body parts, transportation and packaging, etc. Excellent thermal insulation effect, stable and lasting thermal insulation effect, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

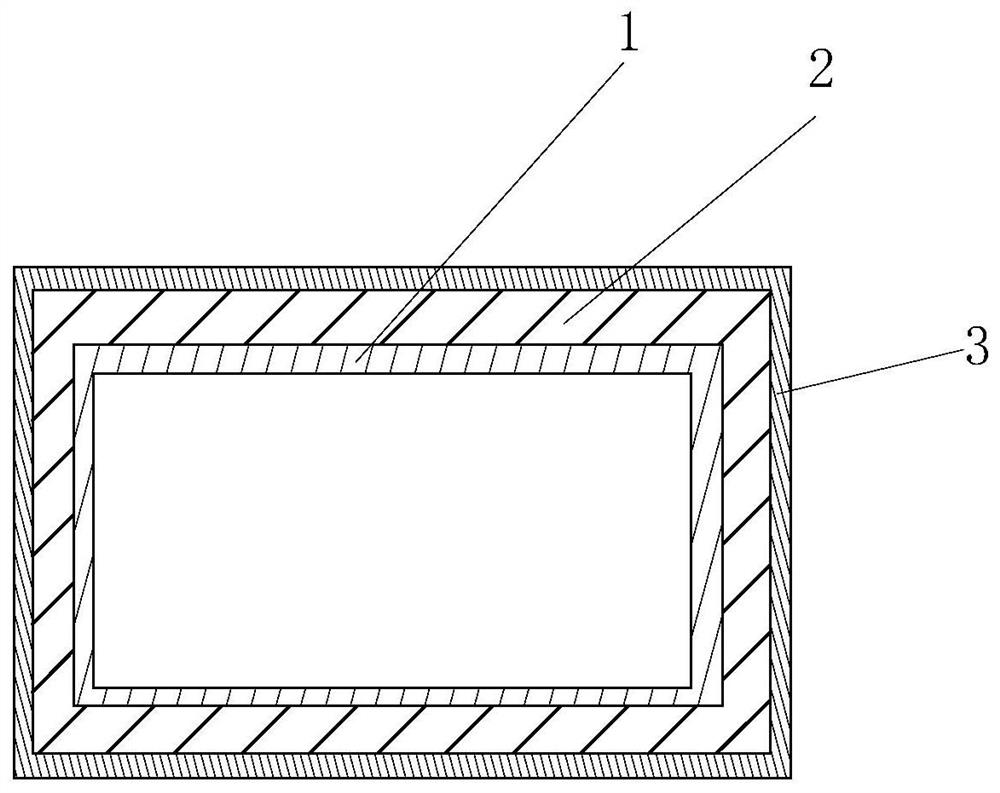

[0049] See figure 1 , The rail vehicle air-conditioning duct pipe of this embodiment is a composite pipe, including a three-layer structure, which is an inner side layer 1, a fiber-reinforced airgel felt layer 2 and an outer side layer 3 from the inside to the outside.

[0050] In this embodiment, both the inner side layer 1 and the outer side layer 3 are cured prepregs.

[0051] Prepreg is a fiber composite material, which is flexible when uncured and can adapt to different shapes of the mold, and the prepreg has great viscosity when uncured; the cured prepreg is shaped and has strength.

[0052]The prepreg comprises the following components in parts by weight: 50-65 parts of fiber fabric, 20-48 parts of resin, and 0-18 parts of auxiliary agent. The additives are determined according to the resin selected for the prepreg, including curing agent, curing accelerator, thickener, etc.; each additive corresponds to the selected resin. Among them, the fiber fabric is any fabric t...

Embodiment 2)

[0069] The rest of the rail vehicle air-conditioning duct pipe of this embodiment is the same as that of Embodiment 1, except that the inner side layer 1 and the outer side layer 3 are obtained by curing epoxy resin prepreg.

[0070] The epoxy resin prepreg of the present embodiment consists of the following components in parts by weight: 50 parts of 800g / m 2 Biaxial fabric, 40 parts of epoxy resin E51, 4 parts of dicyandiamide curing agent, 2 parts of methylimidazole accelerator, 4 parts of flame retardant ammonium polyphosphate.

[0071] The rest of the preparation method of the rail vehicle air-conditioning duct pipe of the present embodiment are the same as claim 1, except that:

[0072] Step ⑥Put the mold as a whole into the drying room, keep the pressure in the vacuum film at -0.085~-0.01MPa; turn on the heating, slowly rise to 120°C~150°C, after the material is solidified, slowly cool down and demould, and the obtained air duct is made of The fiber-reinforced airgel fe...

Embodiment 3)

[0074] The rest of the rail vehicle air-conditioning duct pipe of this embodiment is the same as that of Embodiment 1, except that the inner side layer 1 and the outer side layer 3 are obtained by curing cyanate resin prepreg.

[0075] The cyanate ester resin prepreg of the present embodiment consists of the following components in parts by weight: 50 parts of 800g / m 2 Biaxial fabric, 40 parts cyanate ester resin, 2 parts cobalt naphthenate, 2 parts nonylphenol.

[0076] The rest of the preparation method of the rail vehicle air-conditioning duct pipe of the present embodiment are the same as claim 1, except that:

[0077] Step ⑥Put the mold as a whole into the drying room, keep the pressure in the vacuum film at -0.085~-0.01MPa; turn on the heating, slowly rise to 150~180°C, after the material is solidified, slowly cool and demould, the obtained air duct tube is made of fiber The reinforced airgel felt layer 2 is composed of cyanate ester composite materials cured on its inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com