Multifunctional rolling machine

A rolling machine, multi-functional technology, applied in the direction of presses, lamination, presses using rotating pressure members, etc., can solve the problems of poor quality of belt material transportation, poor rolling effect, and belt slippage, etc., to achieve Easy to operate, avoid running deviation and avoid slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

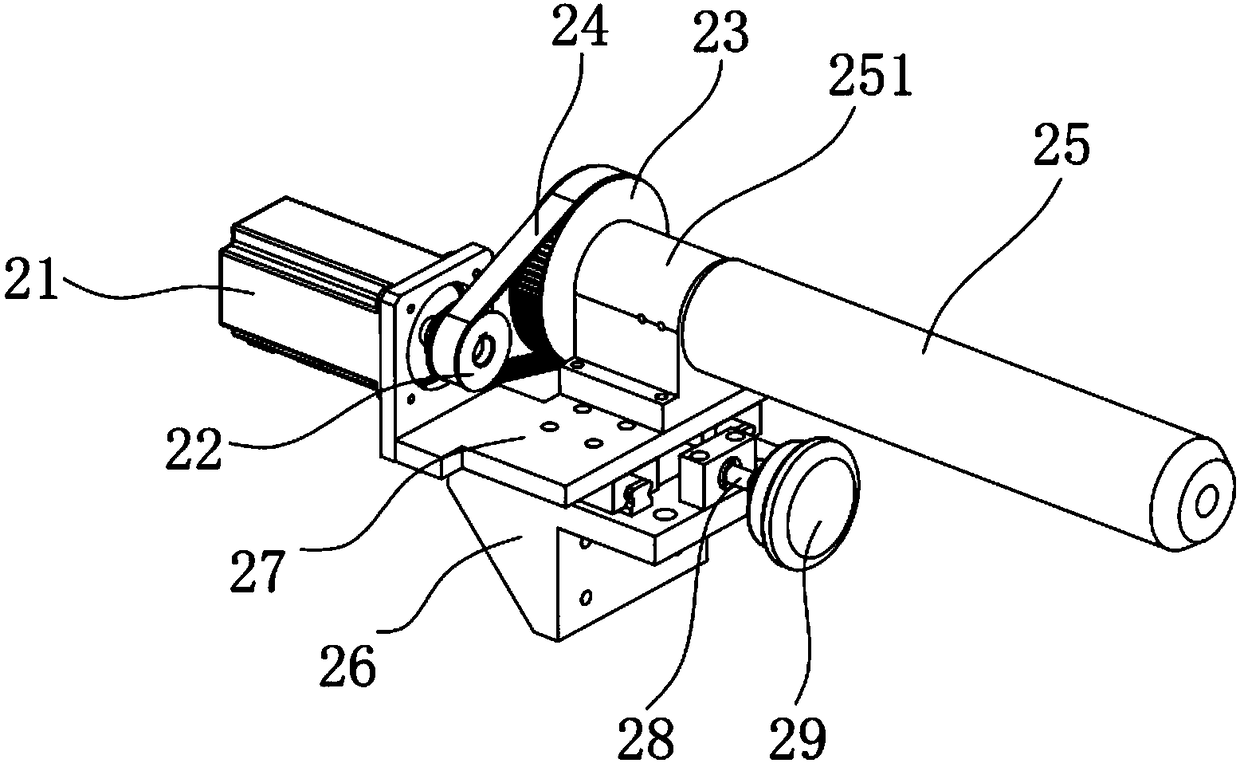

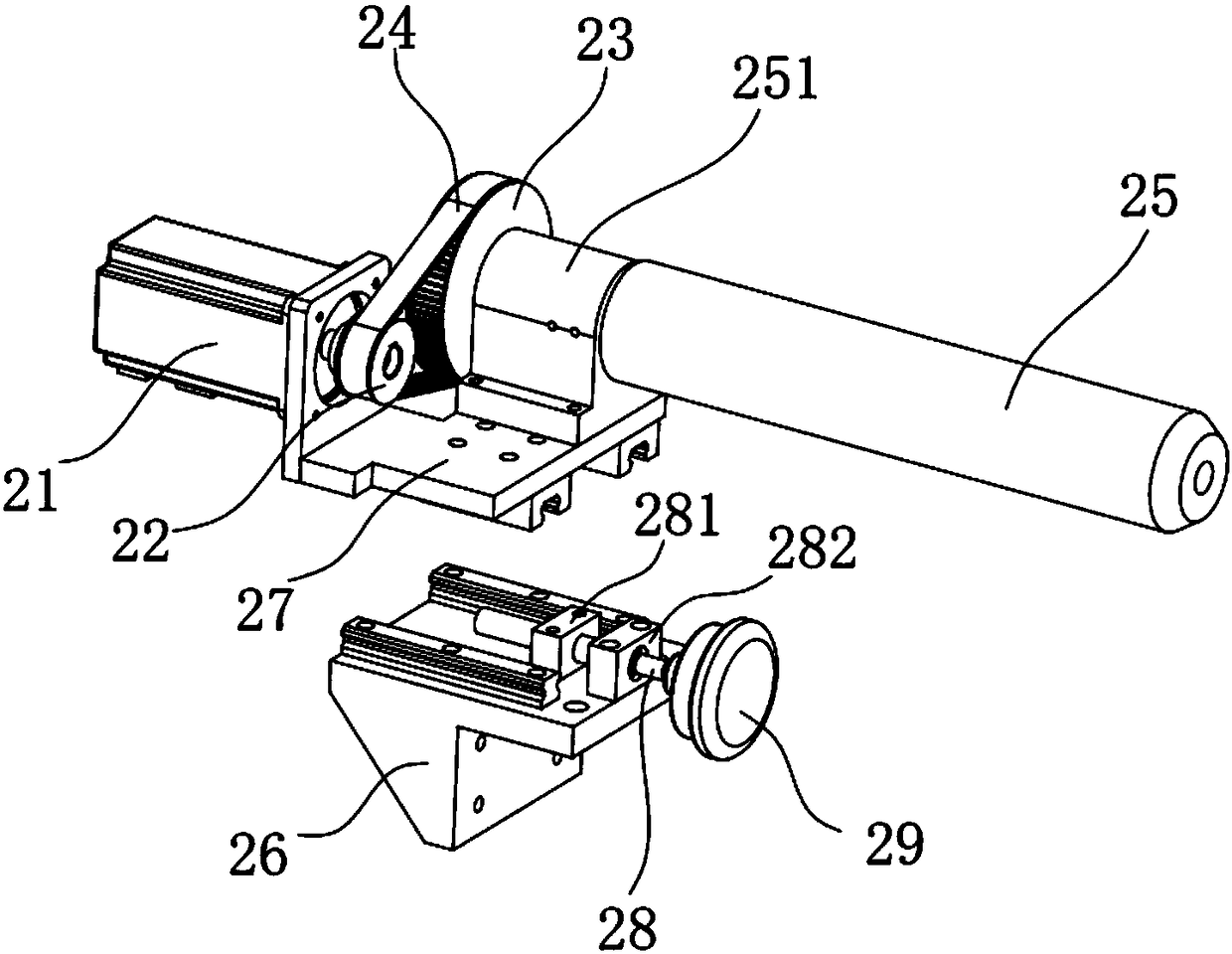

[0033] Such as figure 1As shown, the present invention provides a multifunctional rolling machine, comprising: a frame 10; a plurality of retractable roller units 20, which are arranged on the frame 10, and the horizontal etc. between the retractable roller units 20 The spacing is arranged side by side; at least one rolling unit 30 is arranged on the frame 10 and below the take-up roller unit 20, such as Figure 4 to Figure 7 As shown, the rolling unit 30 includes a bracket 31 fastened on the frame 10, a driving roller unit arranged on the bracket 31, a roller unit arranged on the bracket 31 and located on the driving roller unit The pressure roller unit directly above; the conveyor belt 50, which is stretched on the drive roller unit; and the pressure sensor unit 70; wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com