Advanced flower equipment

A flower and equipment technology, applied in the field of flowers, can solve the problems of non-adjustable flow, inconvenient filling and collection, and insufficient mixing when the nutrient solution is discharged, and achieve the effect of simple structure, enhanced strength, and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

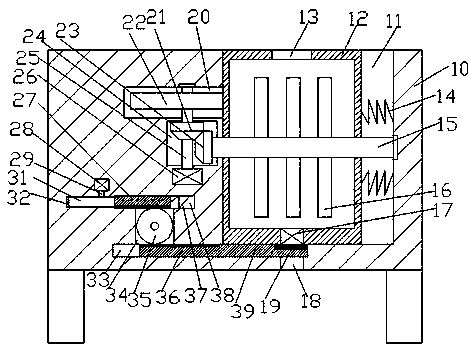

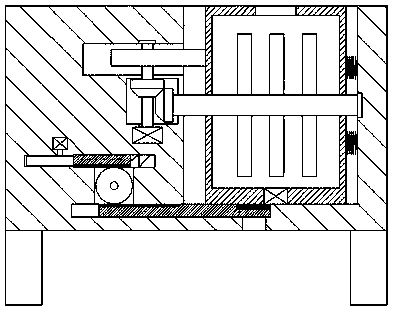

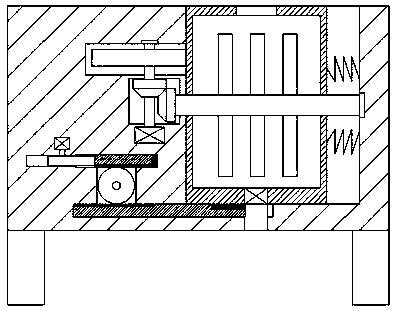

[0015] Such as Figure 1-Figure 4 As shown, an advanced floral equipment of the present invention includes a fixed base 10, and the fixed base 10 is provided with a cavity 11 whose top communicates with the outside, and the cavity 11 is provided with a box body 12, and the box body 12 is connected with the cavity 11 by sliding fit, the top wall of the box body 12 is provided with an inlet 13 communicating with the outside, the bottom wall of the box body 12 is provided with an on-off valve 17, and the bottom wall of the cavity 11 is connected with a The discharge pipe 18 corresponding to the switching valve 17, the first spring 14 fixedly connected to the inner wall on the right side of the cavity 11 is arranged symmetrically up and down on the left side of the box body 12, and the left and right sides of the box body 12 are provided with The first rotating shaft 15, a plurality of blades 16 are arranged at equal intervals on the first rotating shaft 15, the right end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com