Saw-toothed woven tape

A zigzag, webbing technology, applied in the webbing field, can solve the problems of poor ventilation effect, poor comfort, lack of air permeability, etc., and achieve the effect of simple production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

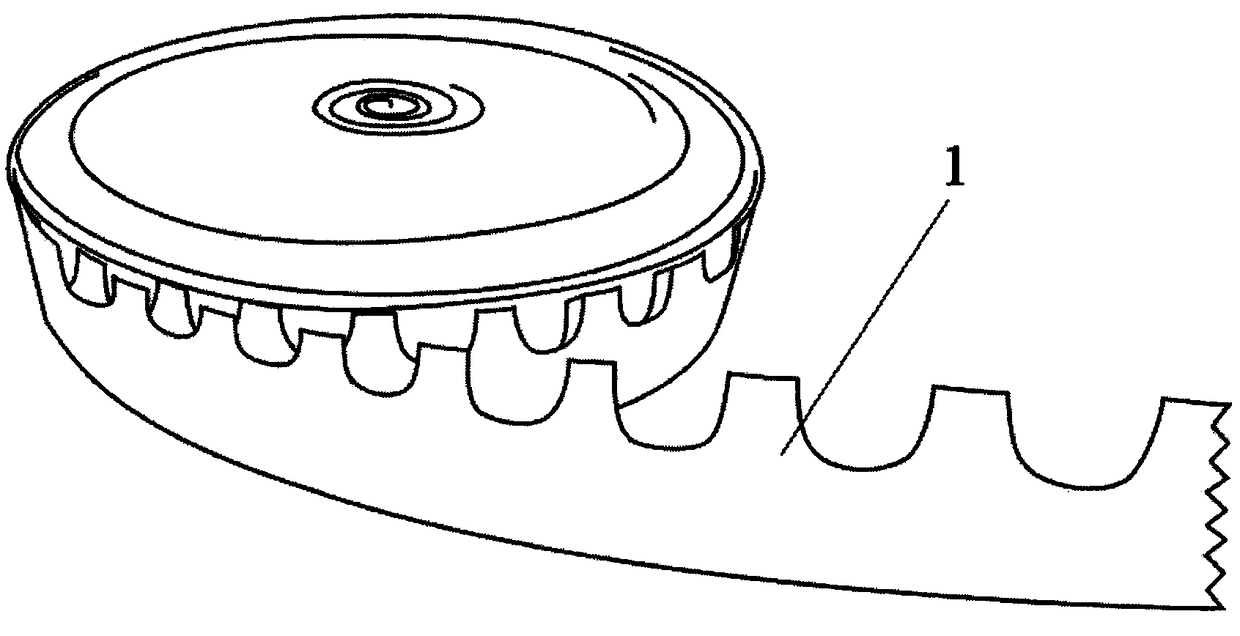

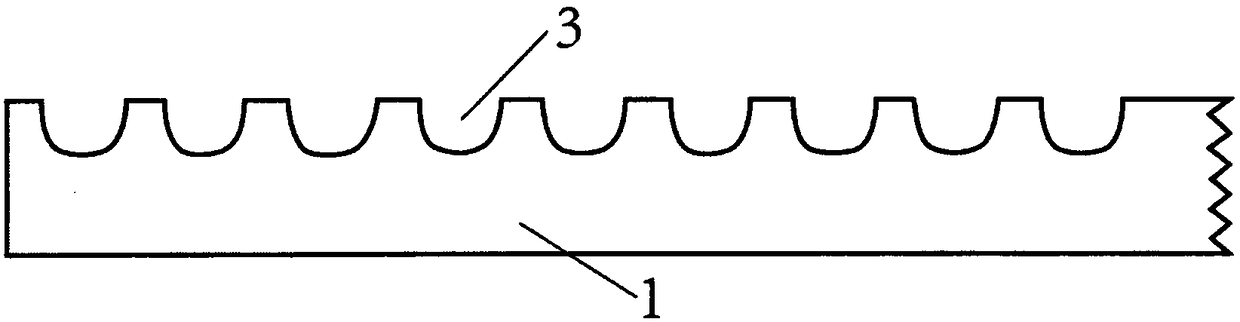

[0023] Such as figure 1 , 2 As shown, it is a zigzag webbing provided by the present invention, one side of which is zigzag. The height of the sawtooth 3 is 1 / 3 of the total width of the ribbon 1. The outer surface of the ribbon 1 is provided with a waterproof coating, and the waterproof coating is a PU coating or a PA coating.

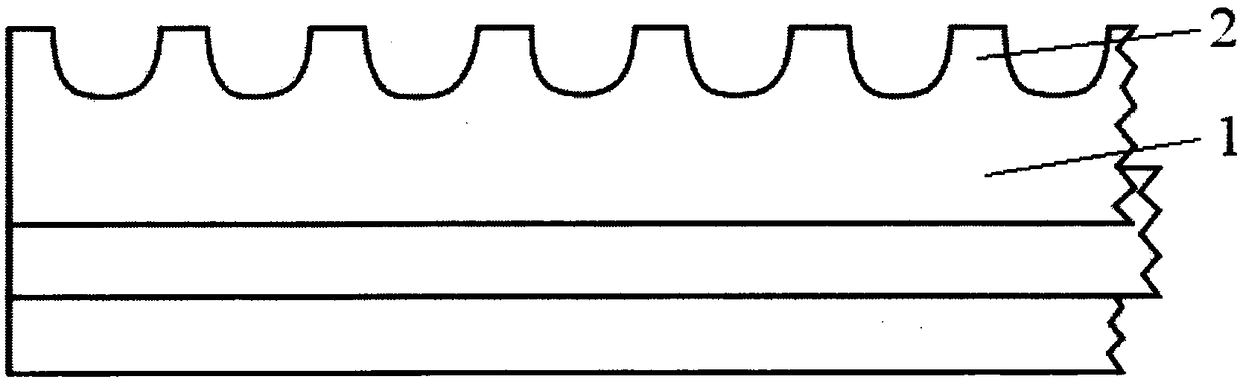

[0024] Such as Figure 3-5 As shown, the sewing product using the above-mentioned zigzag webbing provided by the present invention is made of multi-layer webbing 1 sewn by sutures 2 along the length direction of the webbing, and the sides of the zigzags 3 of each layer of webbing 1 are arranged upwards. , the bottom of the last layer of webbing completely covers the outside of the sawtooth 3 part of the next layer of webbing 1 . The 1 / 3 of the height of the sawtooth 3 of each layer of webbing 1 is provided with sutures 2 .

[0025] Such as Figure 6-9 As shown, the webbing is used to make raincoats, and the webbing 1 is cut according to the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com