Spline shaft mechanism for agricultural machine and low in use cost

A technology for agricultural machinery and spline shafts, applied in mechanical equipment, shaft couplings, rigid shaft couplings, etc., can solve the problem of unbalanced force on spline shafts and bushings, easy wear of spline shafts, and limited protrusions. Ring wear and other problems, achieve the effect of force balance, increase service life and reduce use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through the accompanying drawings and embodiments. However, it should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the scope of the present invention.

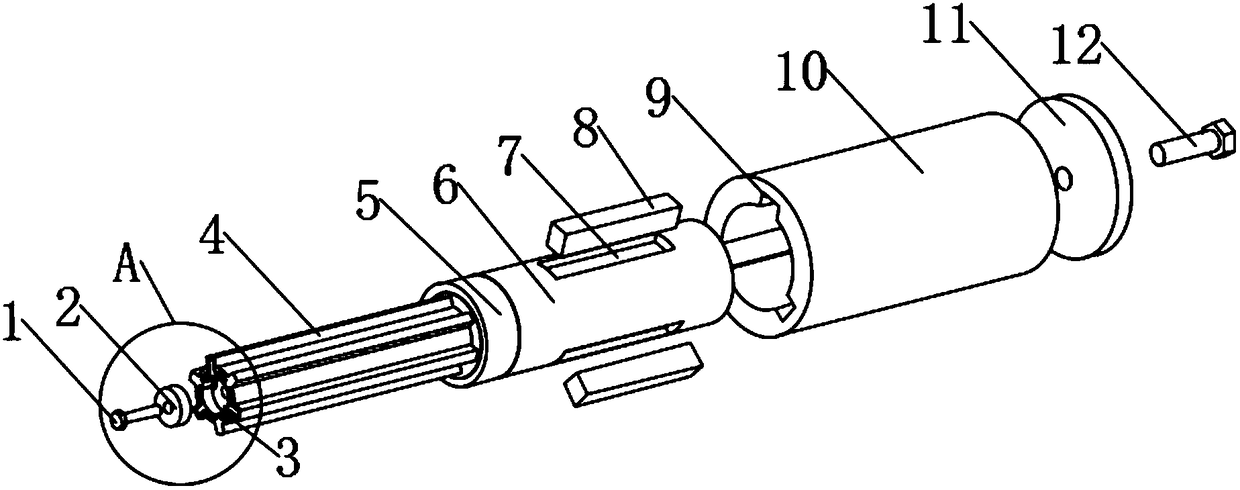

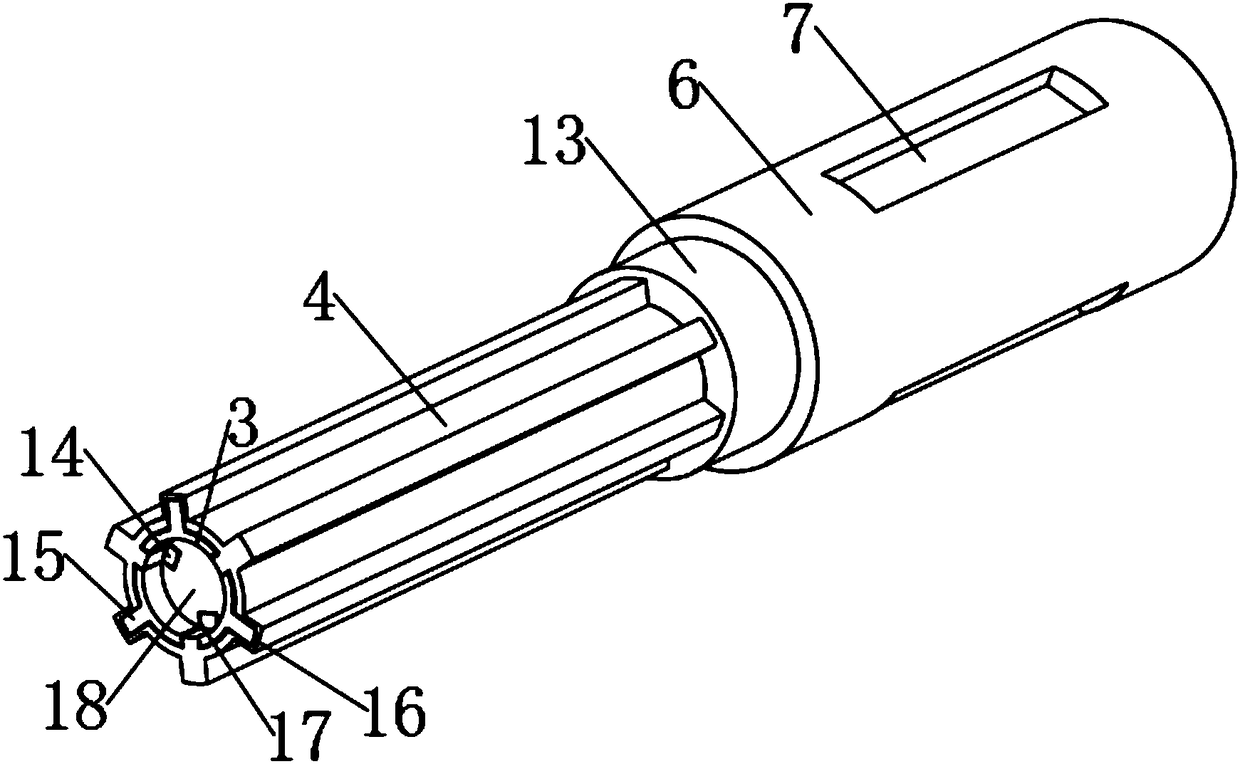

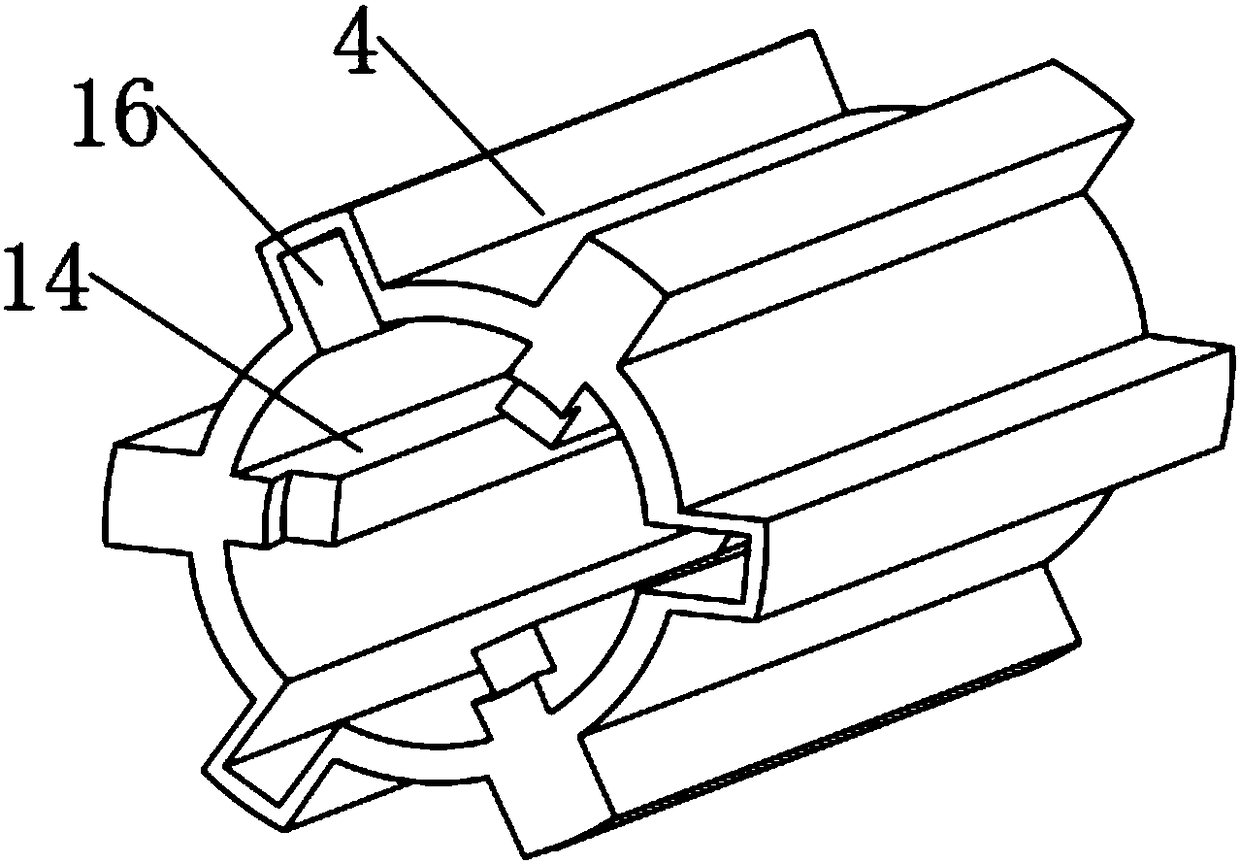

[0028] see Figure 1-4 , the present invention provides a technical solution: a low-cost spline shaft mechanism for agricultural machinery, including: a spline shaft 3, a spline sleeve 4, a connecting section 6 and a shaft sleeve 10; 4 sets of spline sleeves Set on the outer ring of the spline shaft 3, the outer ring of the spline shaft 3 is fixed with three spline outer teeth 15 in a circular array, and the inner ring of the spline shaft 3 is provided with three teeth in a circular array. Spline outer ring tooth grooves 17, three spline outer ring teeth 15 and three spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com