Movable tail wheel mechanism of double-rope coal mine transportation system

A transportation system and mobile technology, applied in conveyors, underground transportation, mechanical conveyors, etc., can solve the problems of cumbersome disassembly of the tail wheel mechanism, troublesome installation and debugging, and increased labor input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

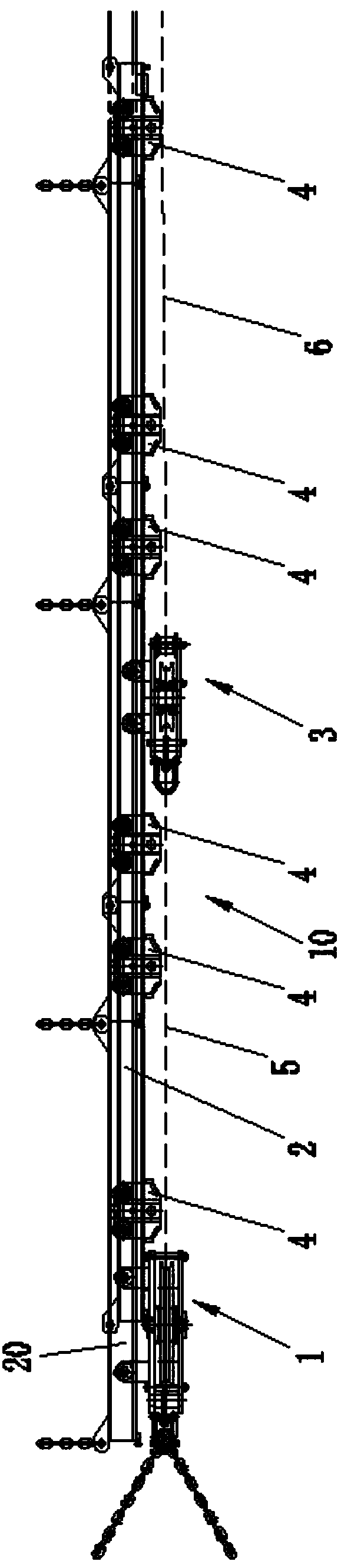

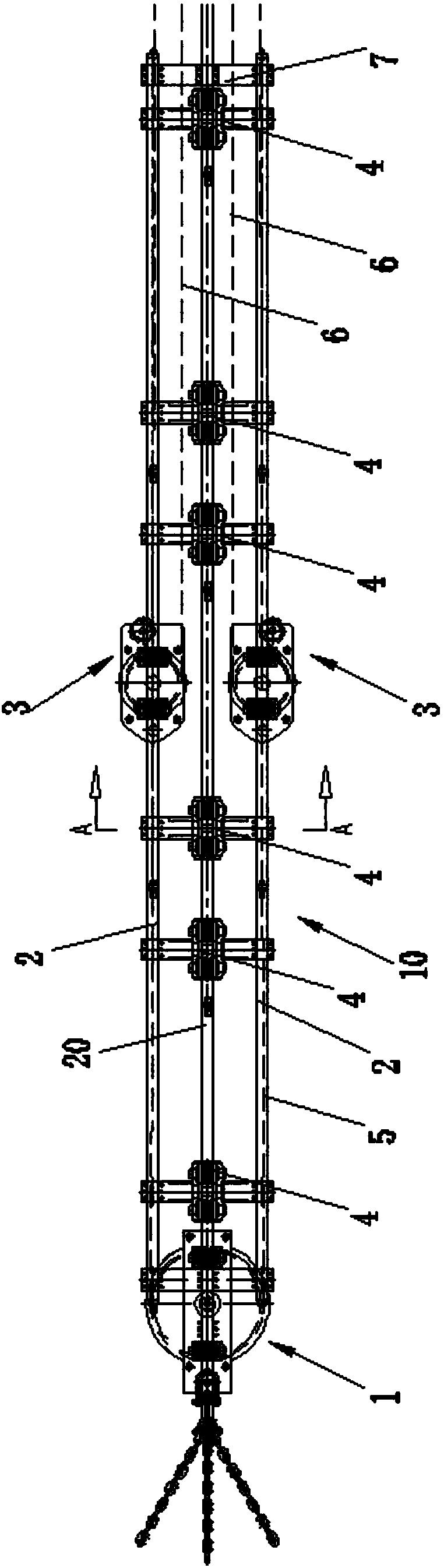

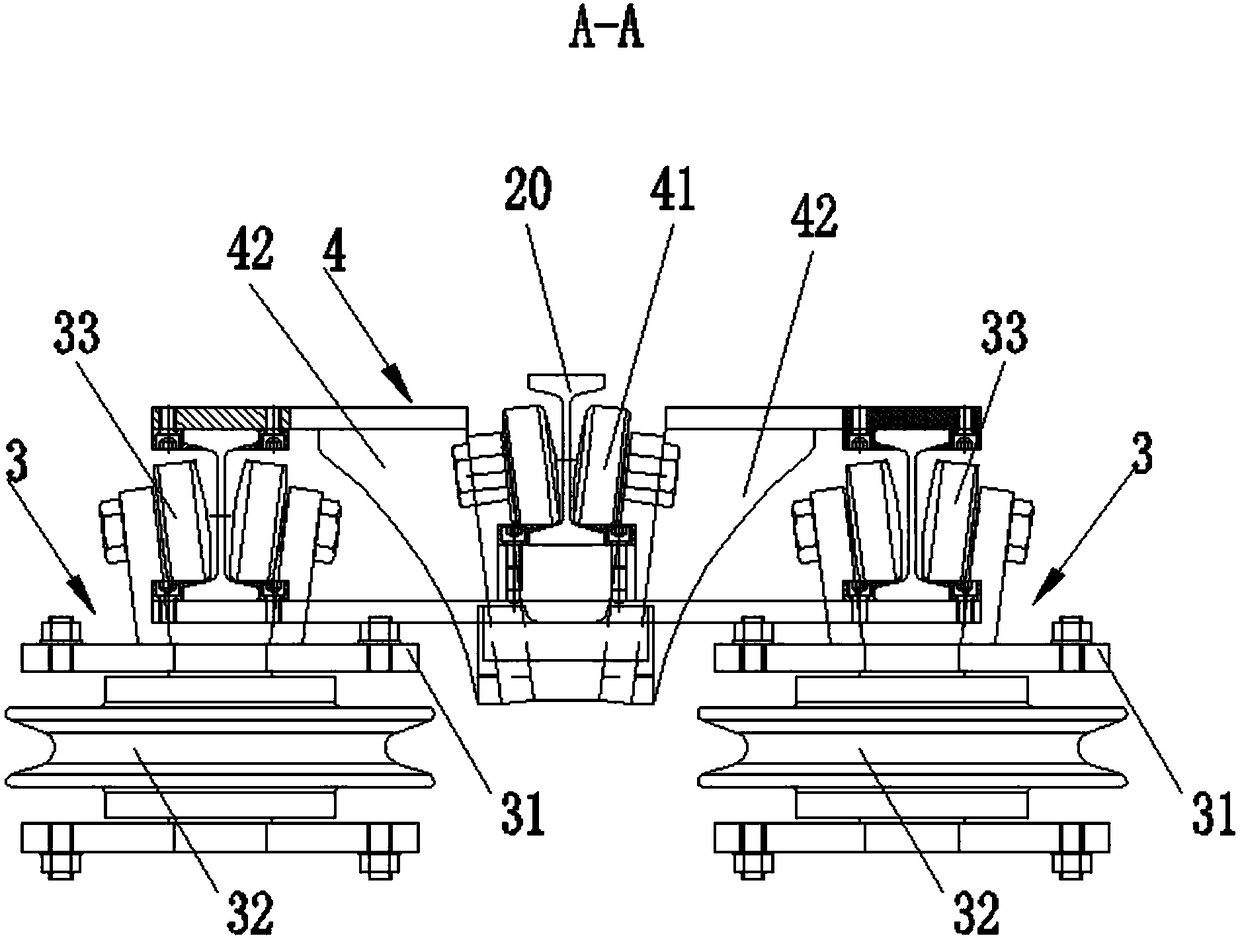

[0015] see figure 1 , 2 , Shown in 3 and 4, a mobile tail wheel mechanism of a double-rope coal mine transportation system includes a tail wheel mechanism 10 installed at the end of the main track 20 of the coal mine transportation system, and the tail wheel mechanism 10 includes a tail wheel assembly 1, two A balance slide rail 2, two sets of balance slide tail wheels 3, a balance slide rail buckle seat 4 and a balance steel wire rope 5, the balance slide rail buckle seat 4 is slidingly connected with the main track 20, and the two balance slide rails 2 Fixed on the rail buckle seat 4 of the balanced slide rail, and located on both sides of the main rail 20, the two sets of balanced sliding tail wheel sets 3 are slidingly connected with the corresponding two balanced slide rails 2, and the two traction wire ropes 6 bypass the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com