Storage rack storing and taking method

一种货架、货物的技术,应用在仓储系统领域,能够解决起重工具行动不灵活、仓储堆放工作困难、机器价格昂贵等问题,达到码放整齐、提高仓储效率、行动灵活方便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

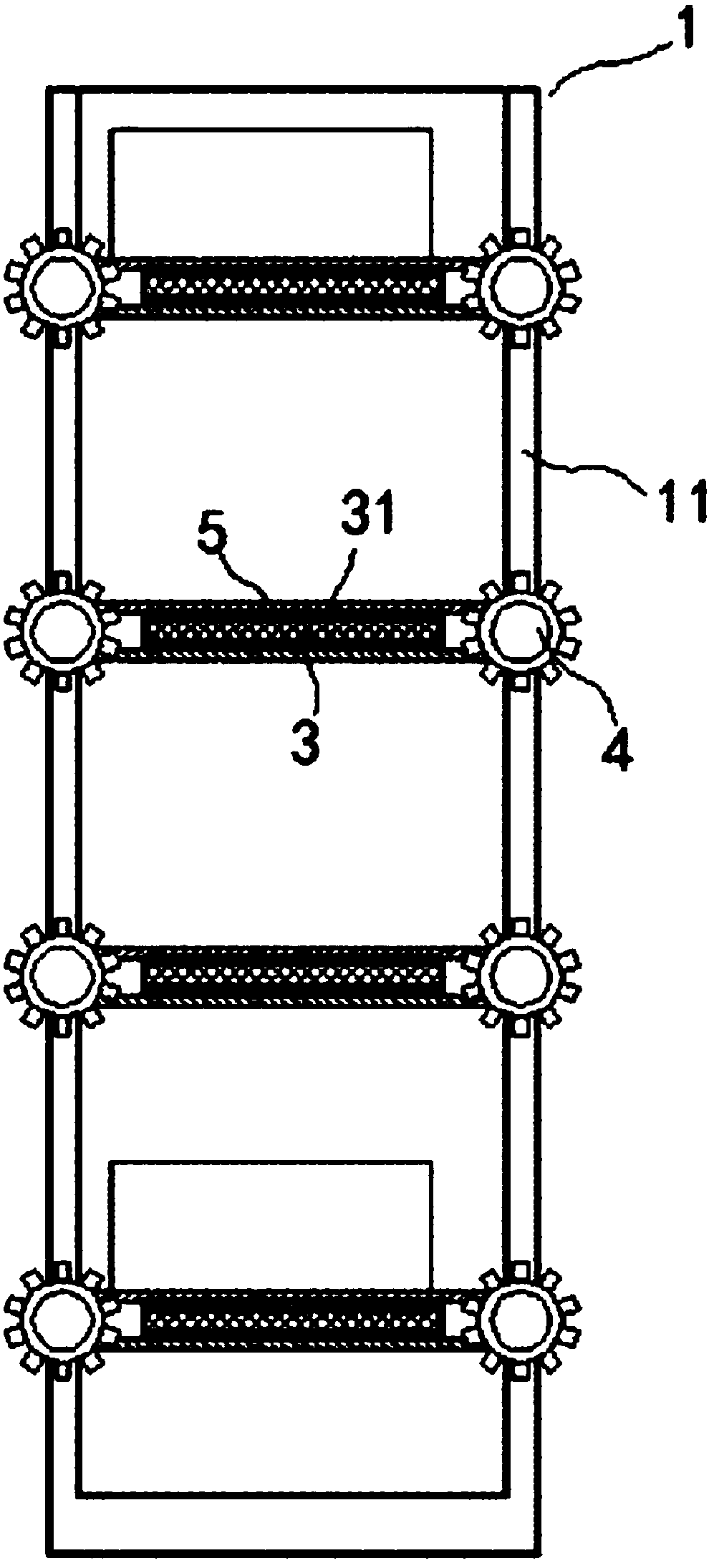

[0016] exist figure 1 , figure 2 In the shown embodiment, the easy-access shelf system includes a storage rack 1 and a storage cart 2; the storage rack 1 includes a vertical support rod 11, on which the support rod 11 is equidistantly fixed from top to bottom There is a support plate 3; in this embodiment, the support plate 3 is made of a heat storage plate, and friction heat sheets 31 are fixed on the upper and lower surfaces of the heat storage plate; installed on the two symmetrical sides of the support plate 3 There are rollers, and transmission wheels 4 are fixedly installed at the two ends of each roller, and the transmission wheels 4 are made of ferromagnetic material; a conveyor belt 5 is sleeved between the two rollers; the conveyor belt 5 can be Rotate around the support plate 3 under the drive of the roller;

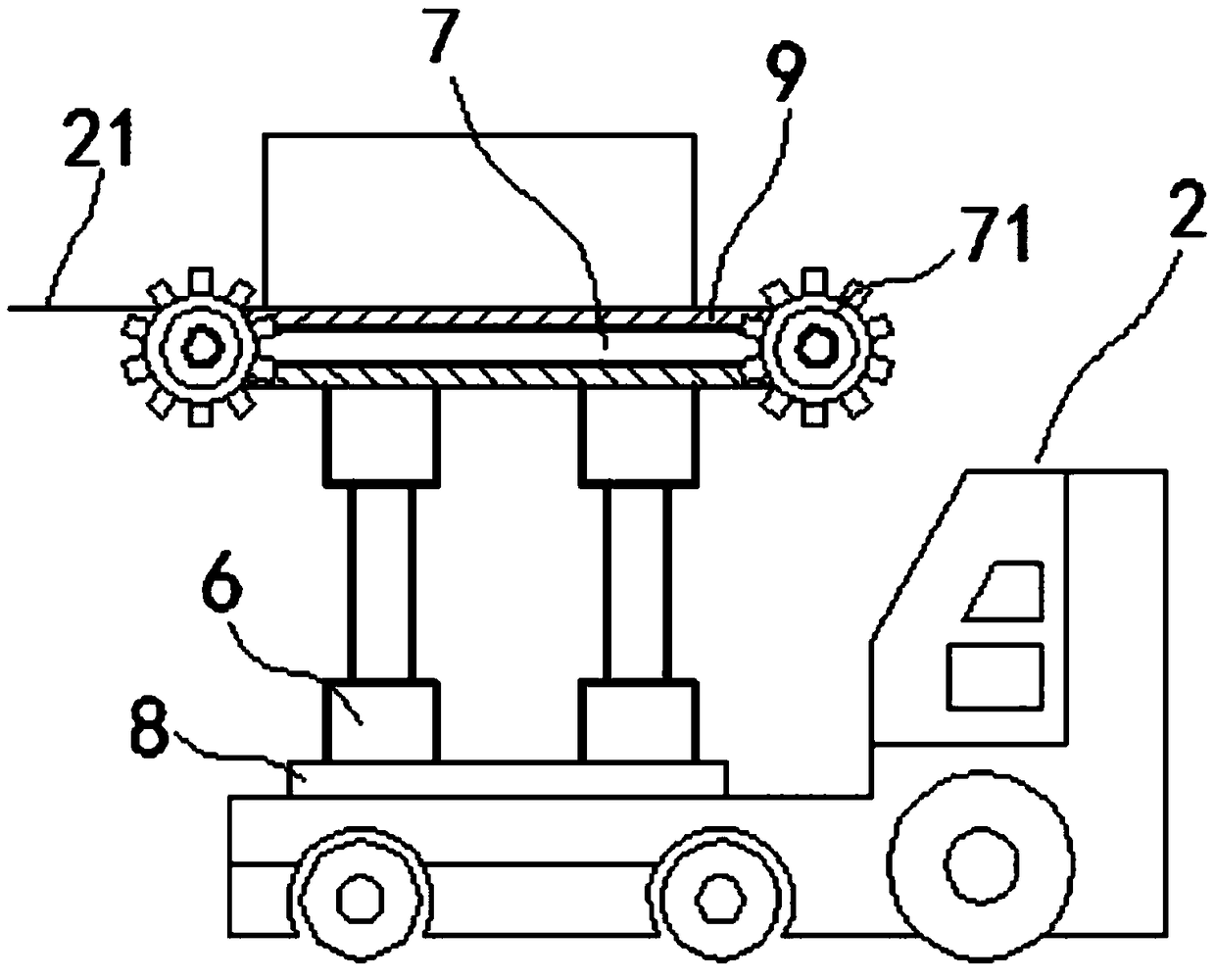

[0017] The storage vehicle 2 includes a driver's cab, a base, a lifting rod 6 and a transfer plate 7, and a steering wheel 8 is also connected between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com